Secure the saw to a base (Fig. 7)

Use the two plastic sliding blocks to

secure the saw to a base so that it will

not move when cutting tile.

1. Place the s-clamp supports (1)

over the two front rubber feet (2).

2. Position the saw on a work surface

so that the edges of the s-clamp

supports (1) fit against the edge of

the work surface.

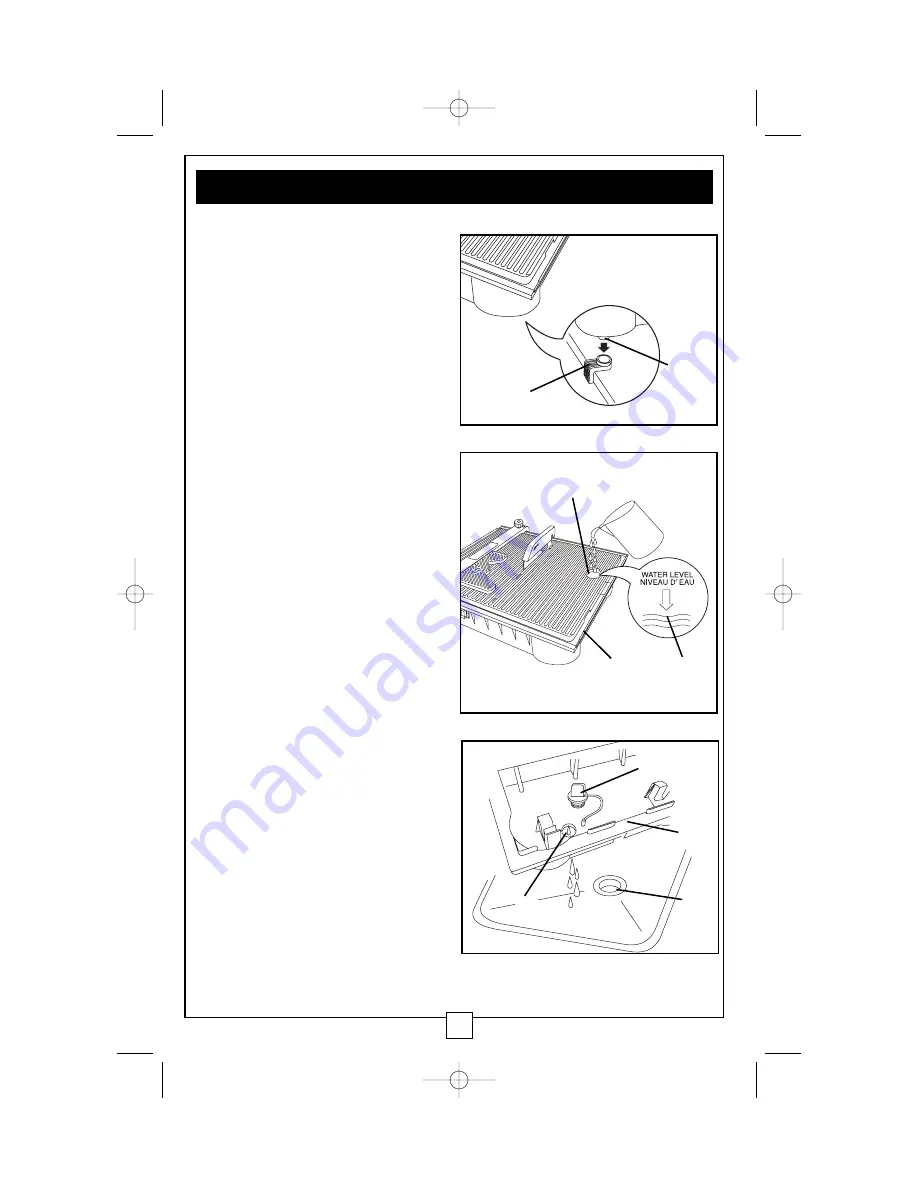

Add water (Fig. 8)

1. Lift up the tilting table (1) and

make sure the drain plug is in the

base and fits snugly. Lower the

tilting table.

2

Remove the cap from the port (2)

on the tilting table.

3. Pour water through the port (2)

into the base. Look through the

port and make sure the water level

does not exceed the upper-most

indicator line (3) on the water level

gauge.

4. Replace the port cap.

Drain water (Fig. 9)

1. Turn OFF the power and unplug

the wet tile saw.

2. Remove the tilting table from the

base (1).

3. Place the wet tile saw over a sink

or drain (2).

4. Turn and pull up on the drain

plug (3) to remove it from the

base. Allow the water to drain out

of the opening (4) in the base.

VI. Assembly and adjustments - continued

12

Fig. 7

1

2

Fig. 8

3

1

2

Fig. 9

2

1

4

3

MC_WetTileSaw 55-6829 E 3/17/05 4:53 PM Page 12