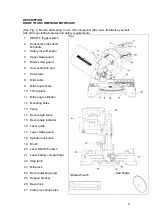

Installing the blade

IMPORTANT: Do not use thin-kerf blades.

Thin-kerf blades can deflect and contact

the guard, which can cause injury to the operator.

1. Match the arrow on the blade with the arrow on the upper blade guard. Make sure

the blade teeth are pointing downward. Install the selected blade by sliding the

blade into the upper blade guard and then placing the blade into position.

2. Install the outer flange.

IMPORTANT:

Make sure the flat side of the flanges is placed against the blade.

3. Press and hold the spindle lock button, turn the blade screw counter-clockwise

using the supplied wrench until the lock engages. Securely tighten the blade

screw securely.

4. Rotate the blade screw guard into position and securely tighten the screw

clockwise. Remove and store wrench in a safe place.

5. Lower the saw head and check the clearance between the blade and the mitre

table. The blade should rotate freely.

ADJUSTMENT

WARNING:

Disconnect plug from power source before performing any

assembly, adjustment or repair to avoid possible injury.

IMPORTANT: Do not use thin-kerf blades.

Thin-kerf blades can deflect and contact

the guard, which can cause injury to the operator.

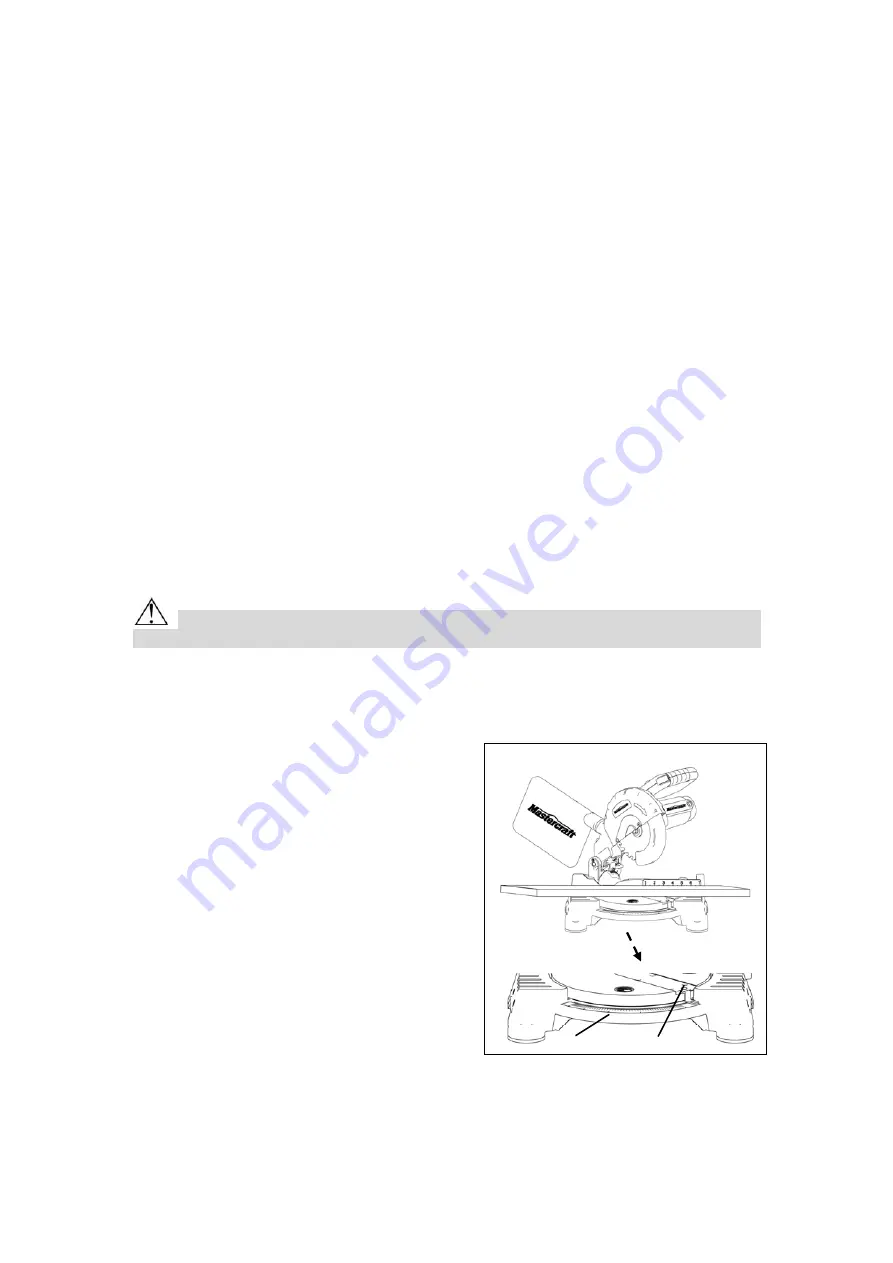

Mitre adjustment

Fig.5

1. Lock the saw head in the down position,

and then loosen the mitre lock by pulling

it upwards.

2. Hold the cutting handle firmly to rotate

the mitre table to any desired angle, and

the mitre table has the most common

angle settings with positive stops at 0°,

15°, 22.5°, 30°, 31.6°, and 45° for quick

and accurate angle.

3. Tighten the mitre lock and release the

saw head.

Mitre angle indicator adjustment (if necessary)

1. Place the mitre table at the zero position

making sure the mitre lock is secured in

position.

2. Loosen the mitre angle indicator screw

and adjust the indicator to the “0” mark on the mitre scale. (See Fig. 5)

3. Tighten mitre angle indicator screw.

Miter scale Indicator screw

11

Summary of Contents for 55-6857-6

Page 17: ...17 ...