MAINTENANCE

23

AIR

-

POWERED 2

-

IN

-

1 NAILER 058

-

8548

-

4

DANGER!

Potential hazard that will result in serious injury or loss of life.

•

Disconnect the tool from the air compressor before performing maintenance/

service, adjusting, clearing jams, reloading, and when it is not in use.

•

Repairs must be performed by a qualified service technician only. Failure to

comply will lead to serious injury or loss of life.

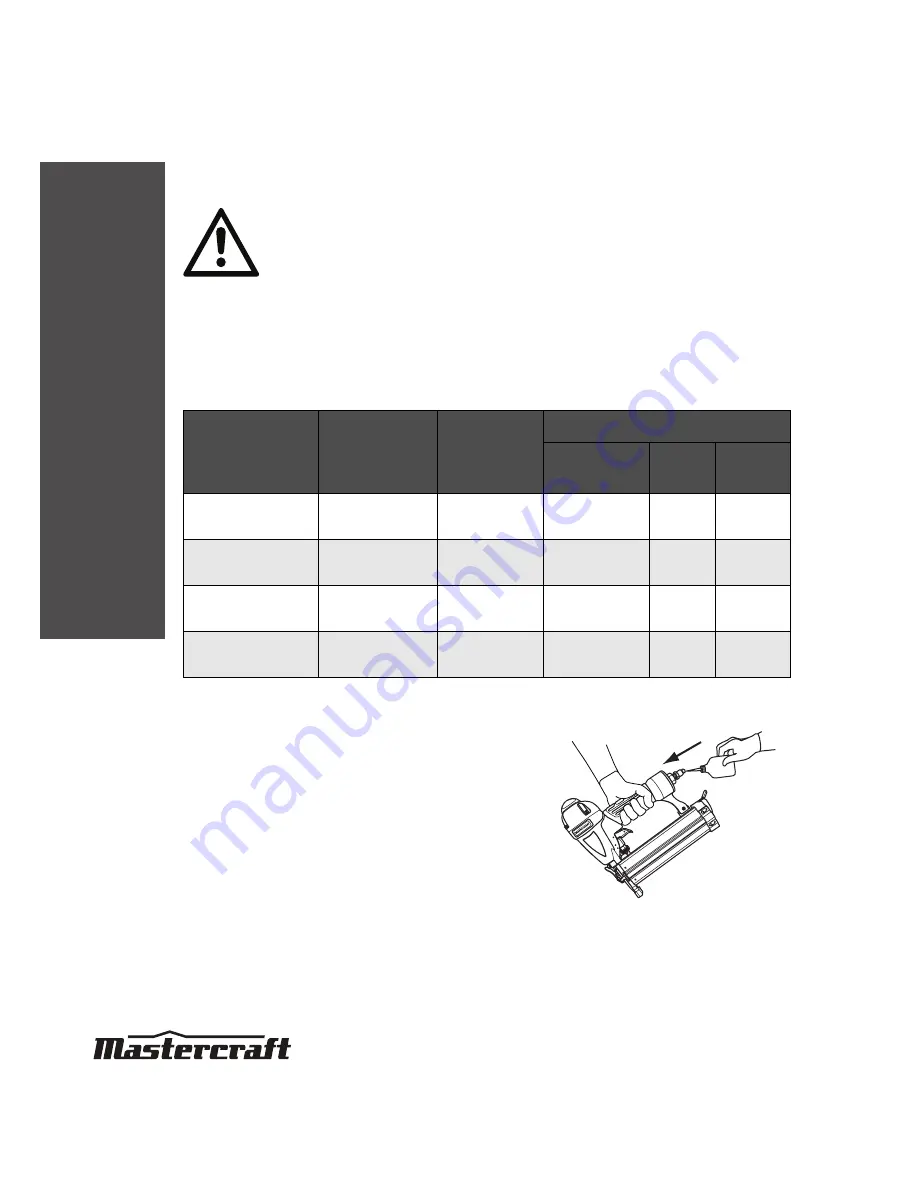

MAINTENANCE

REQUIRED

DESCRIPTION

TOOLS OR

MATERIALS

REQUIRED

MAXIMUM SERVICE INTERVAL

Each Use or

every 2 Hrs

Monthly

As

Needed

General inspection

-

free movement

Trigger, spring,

safety mechanism

None

X

In

-

depth inspection

Worn or broken

parts

X

X

Replace worn or

broken parts

X

Lubrication

See below

Pneumatic tool

oil

X

•

Lubrication: If the Air

-

powered 2

-

in

-

1 Nailer and

the compressor are not equipped with an in

-

line

lubrication system, place up to 6 drops of pneu-

matic tool oil into the air inlet before each work

day or after every 2 hours of continuous use,

depending on the characteristics of the workpiece

and type of fasteners used.

MC-588548-21

Summary of Contents for AIR-POWERED 2-IN-1 NAILER

Page 1: ...INSTRUCTION MANUAL AIR POWERED 2 IN 1 NAILER 058 8548 4...

Page 3: ......

Page 21: ......