33

32

model no. 054-1232-4 | contact us 1.800.689.9928

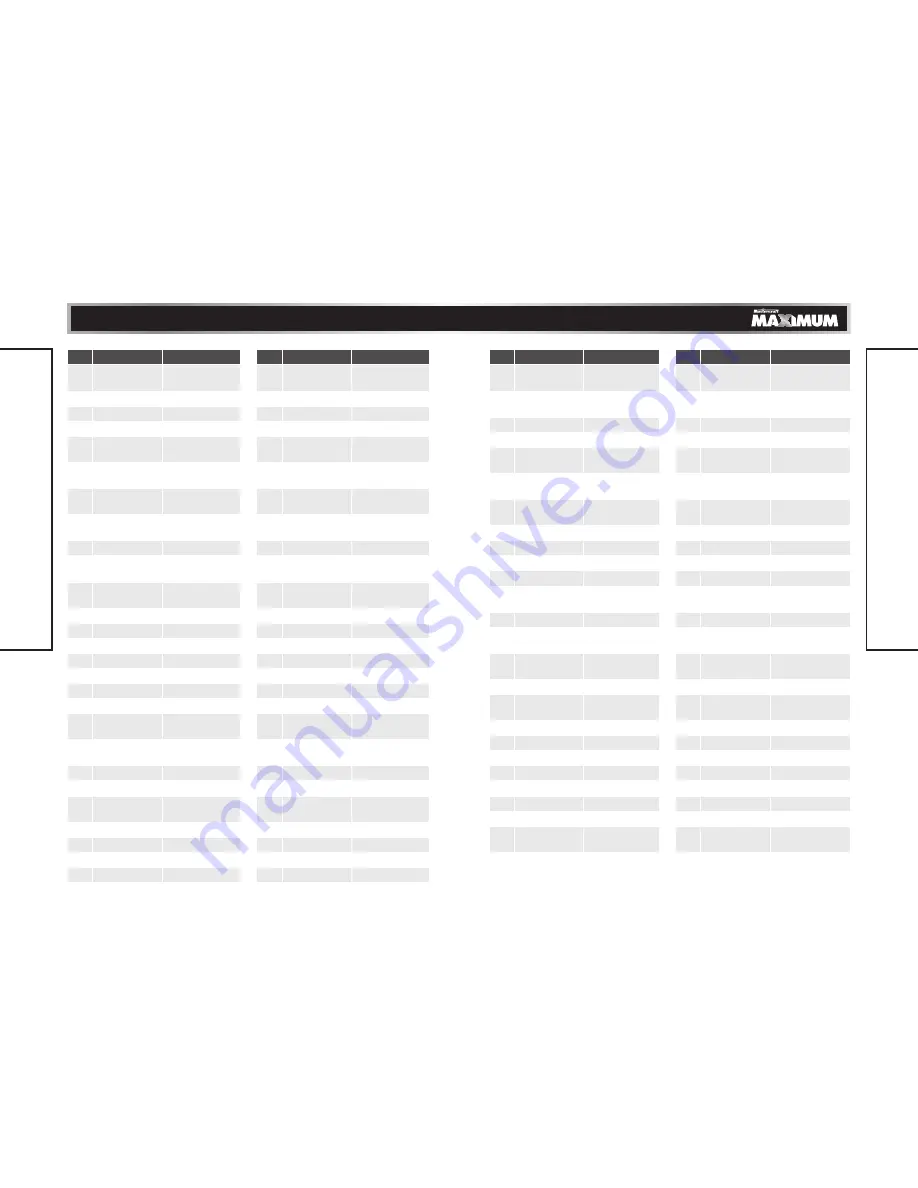

No.

Part No.

description

No.

Part No.

description

1

3320601000

Left Housing

Assembly

28

3320103000

Knob Set

2

3420338000

Left Alum Cover

29

3320104000

Knob Assembly

3

3320616000

Push Button

30

3551339000

Bush

4

3121037000

Cord Guard

31

3420945000

Alum Cover

5

4810002000

Power Cord &

Plug

32

5610022000

Tapping Screw

6

5680019000

Hexagon

Wrench

33

3120477000

Bearing Holder

7

3320819000

Left Handle

Assembly

34

3520055000

Aligning

Bearing

8

3320820000

Right Handle

Assembly

35

5610106000

Tapping Screw

9

3660030000

Spring

36

3420946000

Drive Bracket

10

3123857000

Lock Pin

37

3520057000

Lower Sliding

Bearing

11

3320615000

Lock Button

38

3420129000

Sliding Bearing

Support

12

3121459000

Switch Cover

39

5610021000

Tapping Screw

13

3420675000

Hander Lever

40

5650001000

Plain Washer

14

3320105000

Switch Lock A

41

3120444000

Dust Seal

15

3660072000

Spring

42

3120491000

Guiding Block

16

3123856000

Trigger Lock

43

3550213000

Pendulum Pin

17

3120457000

Limiting Piece

44

3660071000

Spring

18

3660054000

Spring

45

3550202000

Pin

19

3700220000

Connecting

Piece

46

3550191000

Pin 1

20

3121471000

Pendulum Lever

47

2822446000

Plunger

Assembly

21

3700536000

Felt Ring

48

3550214000

Crank Roller

22

3700145000

Washer

49

5700022000

Needle Bearing

23

5660027000

Circlips For

Shaft

50

5660007000

Circlips For

Shaft

24

3660050000

Spring B

51

3700183000

Washer C

25

3700191000

Cap

52

3550993000

Gear Set

26

5610040000

Tapping Screw

53

5700030000

Needle Bearing

27

2822669000

Link Assembly

54

3700203000

Washer 1

No.

Part No.

description

No.

Part No.

description

55

3520058000

Pendulum Plate

80

3660055000

Carbon brush

Spring

56

3700224000

Counterweight

A

81

4870043000

Switch

57

3700225000

Counterweight

82

4890524000

PCB Assembly

58

3700226000

Washer

83

4930004000

Connecter

59

3700184000

Washer D

84

3123861000

Left Indictor

Cover

60

2820588000

Bearing Support

Assembly

85

4540017000

Power Supply

Indicator

61

5700045000

Steel Ball

86

3123860000

Right Indictor

Cover

62

3120016000

Spring Tube

87

3320248000

Vacuum Adapter

63

5620064000

Screw

88

3700675000

Rip Fence

64

3700227000

Washer

89

3124066000

Blade Storage

65

3550201000

Located Pin

90

3420814000

Base Plate

66

2822593000

Roller Support

Set

91

3124065000

Base Plate Cover

67

3400175000

Knob

93

3700236000

Clamp Washer

68

5610079000

Thread Forming

Screw

94

5620013000

Hexagon Socket

Screw

69

3123859000

Switch Actuator

95

3320602000

Right Housing

Assembly

70

3123858000

Lever

96

2822242000

Blowing Knob

71

3660051000

Spring

97

3420339000

Right Alum

Cover

72

3123855000

Link

98

3650099000

Wire Guard

73

2750897000

Rotor

99

3121368000

Guard

74

3700164000

Square Nut

100

3123507000

Transparent Cap

75

2740270000

Stator

101

4360001000

LED

76

5610024000

Tapping Screw

102

2780030000

Laser Set

77

3120234000

Cord Anchorage

103

4890523000

PCB Assembly

78

4960017000

Carbon Brush

104

5700011000

Ball Bearing

79

2820587000

Brush Support

Assembly

105

5700004000

Ball Bearing

If the problem remains unsolved after performing the checks described above,

call the toll-free helpline at 1-800-689-9928.

P

ART

L

IS

T

P

ART

L

IS

T

Summary of Contents for MAXIMUM 054-1232-4

Page 19: ......