A

CCESSORY

I

NSTALLATION

If it becomes necessary to store or

transport the unit where temperatures

could drop below freezing, 32° F, the

pump, solution hoses and valve on the

tools must be protected from freezing

with a solution of automotive radiator

antifreeze.

1

. Mix

1

/

2

gallon of water and

1

/

2

gal-

lon of antifreeze in the solution tank.

Hook up the hoses and tools to the

extractor.

2.

Turn the pump

ON

and press the

valve to let antifreeze mixture fill the

solution line system.

3.

Disconnect solution supply hoses and

vacuum out remaining antifreeze from

the solution tank

4

. To prevent damage to unit, allow the

extractor to reach room temperature

before using. The antifreeze

MUST

be

flushed out of solution system with clean

water, otherwise, the carpet may be

damaged.

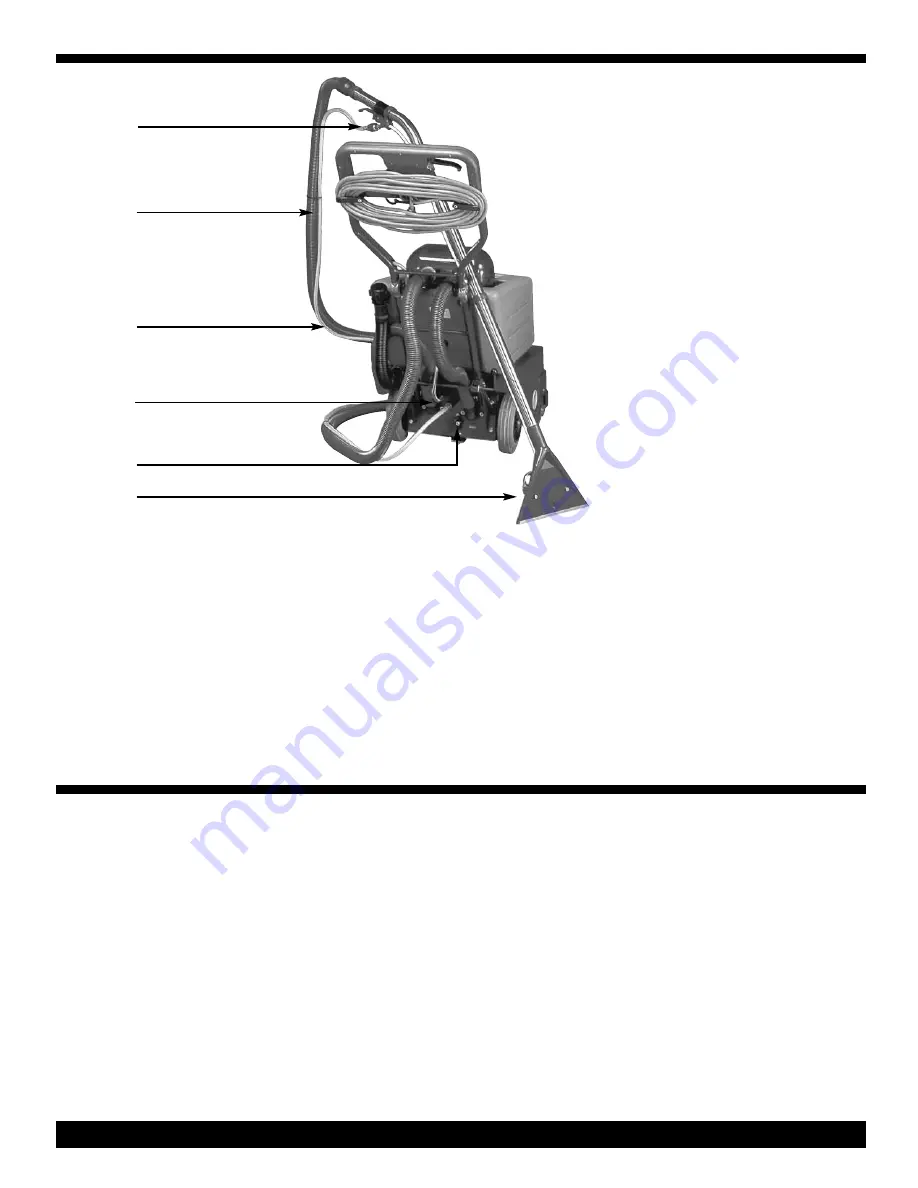

Accessory Tool

Quick-Connect

Accessory Tool

Vacuum Hose

Accessory Tool

Solution Hose

Accessory Tool

Quick-Connect

Solution Control Knob

Cleaning Tool and Wand

P

AGE

7

F

REEZING

T

EMPERATURE

P

RE

-C

AUTIONS

1

. Remove the vacuum hose from the

left side of the tank cover.

2.

Connect the accessory tool vacuum

hose to the left fitting on tank cover and

on to the end of the cleaning tool wand.

Note:

The hose must be connected

tightly.

3.

Connect solution hose to accessory

quick-connect in the back of the extrac-

tor and to quick connect located on the

handle of the tool.

4

. Turn solution control knob in the back

of the extractor to the upright position.

5.

Turn

ON

the solution and vacuum

switches.

DO NOT

turn on brush

switch.

6.

Start cleaning by squeezing trigger

on the wand while slowly pulling the tool

towards you.

7.

When finished, turn

OFF

vacuum and

solution switches, disconnect vacuum

and solution hoses from unit.

8.

Re-connect the extractor’s vacuum

hose to left fitting on the tank cover.

9.

Return the solution control knob to

the normal position.