Page 10

OPERATION

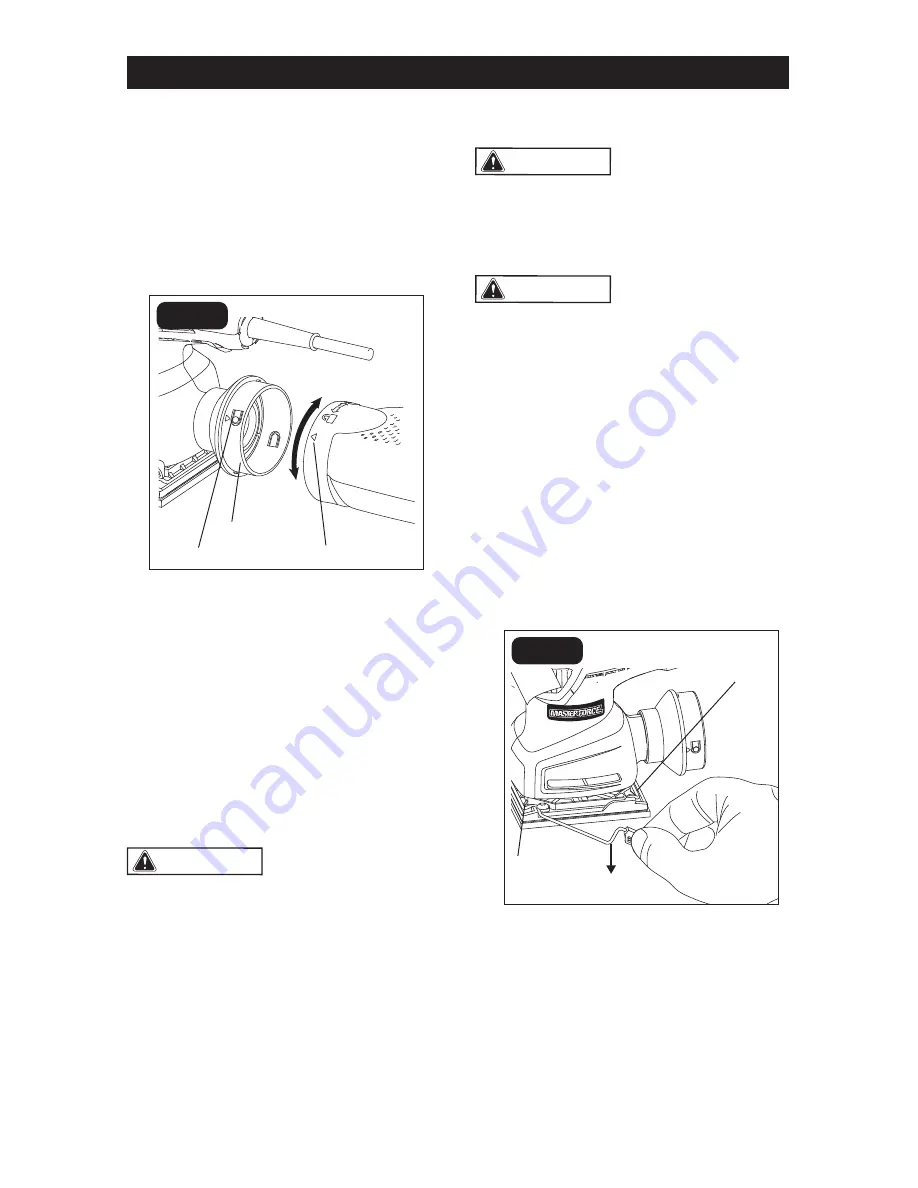

To install:

1. Disconnect the sander from the power

source.

2. Align the indicators on the vacuum

adaptor and the dust box.

3. Slide the dust box forward and push

it onto the adaptor. Rotate the box

clockwise to lock it in place (FIG. 3).

NOTICE: From time to time, clean the

vacuum adaptor with a dry brush. See the

maintenance section for instructions for

cleaning the dust box.

To remove:

1. Disconnect the sander from the power

source.

2. Grip the dust box firmly, rotate it

counterclockwise and pull it out from the

tool (FIG. 3).

WARNING:

Collected sanding dust

from sanding surface coatings such as

polyurethanes, linseed oil, etc., can self-

ignite in the sander dust box or elsewhere

and cause fire. To reduce the risk of fire,

always empty the dust box frequently while

sanding and never store or leave a sander

without totally emptying its dust box. Also

follow the recommendations of the coat-

ings manufacturers.

ATTACHING THE SANDPAPER

WARNING:

Always inspect the

sandpaper before attaching. Do not use

the paper if it is torn or defective.

1. Disconnect the sander from the power

source.

WARNING:

Failure to unplug the

sander could result in accidental starting,

causing possible serious personal injury.

2. Remove any dust or debris from the

platen.

3. The paper clamp levers are located on

each side of the sander and are locked

into the slots on the upper surface of the

platen.

Lift the two levers and disengage them

from the slots in the platen. This will

release the tension on the paper clamps

that hold the paper in position on the

underside of the platen (FIG. 4).

4. Insert the front end of the sandpaper

approximately 1/2 in. under the front

paper clamp.

5. Lift up on the lever that controls the front

paper clamp and lock it back into the slot

on the platen. This will securely clamp

the paper to the front of the platen.

6. Smooth out the sandpaper by pressing

it tightly against the bottom of the pad

(front to back).

FIG. 3

lndicator

Adaptor

Indicator

Unlock

Lock

FIG. 4

Front paper

clamp

Paper clamp

lever

Back paper

clamp