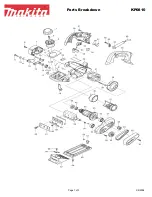

9

3. Clean out all chips or foreign

matter adhering to the cutter

block (8) and the blade.

4. Either turn over the planer blade

(7) or replace it if required.

5. Slide the good blade face up

into the blade retainer (17) of

the cutter block (8). The ridge

along the blade should be on the

opposite side from the clamping

screws (9).

NOTE:

The blades are preset so

that the cutting edge is level, i.e.,

parallel to the surface of the rear

shoe (11).

6. Tighten the clamping screws

(9), ensuring they are tightened

evenly.

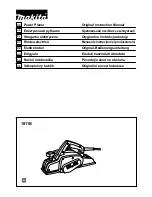

7. Repeat for the second blade,

making sure that both blades

are set to the same cutting level

and positioned in the center of

cutter block (8). Otherwise your

planing surface will be rough and uneven. (Fig. 2-4)

NOTE:

Always change both blades at the same time, and use blades of the

same dimensions and weight, otherwise the resulting imbalance can cause

vibration, poor planing action and shorten the blade and tool life.

CAUTION:

Tighten all the clamping screws (9) carefully when attaching the

blades to the planer. A loose clamping screw could be extremely dangerous.

Regularly check to see they are

tightened securely.

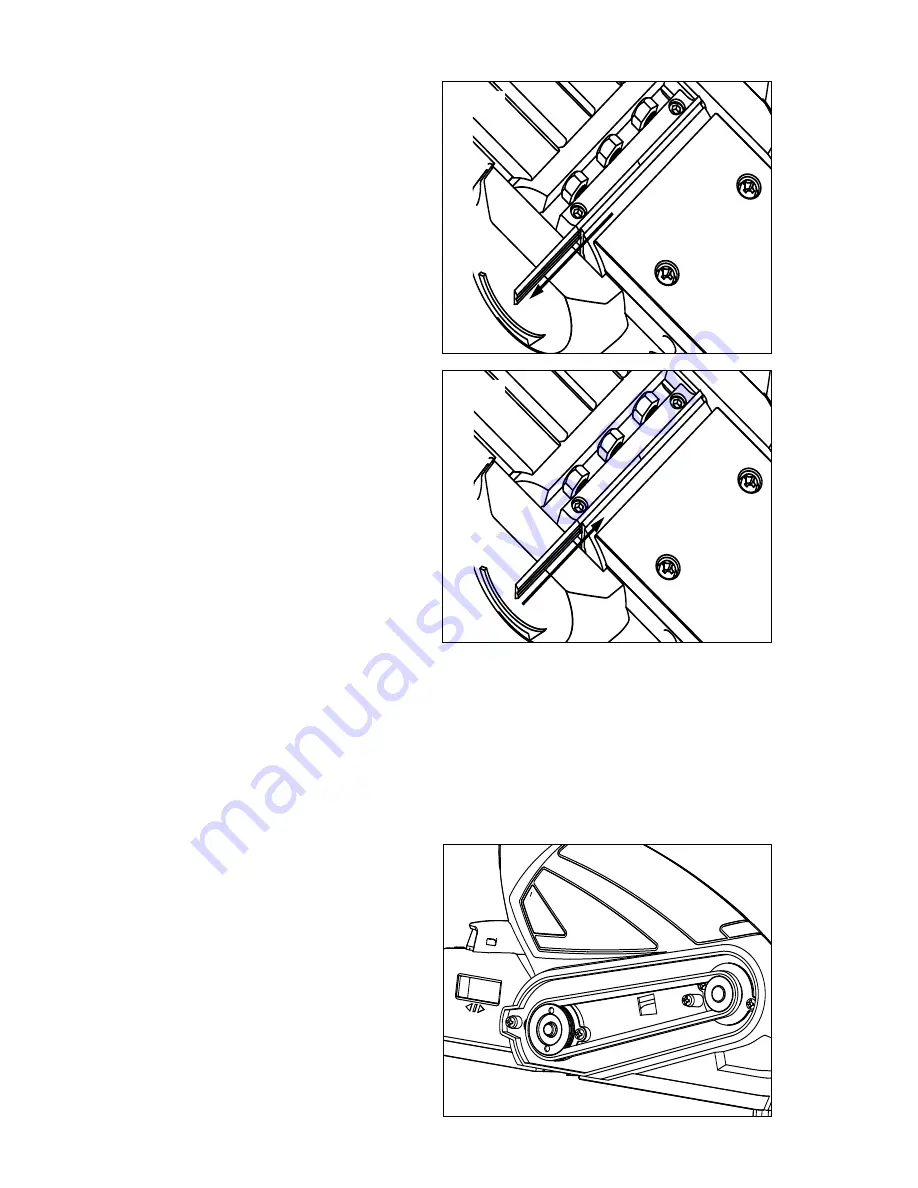

DRIVE BELT REPLACEMENT (Fig.5)

1. Remove the cross-head screws

that secure the drive belt cover

on the left-hand side of the

planer as viewed from the rear.

2. Remove the damaged belt and

use a soft brush to clean the

pulleys and the surrounding

area.

Fig. 3

Fig. 4

Fig. 5