Page 16

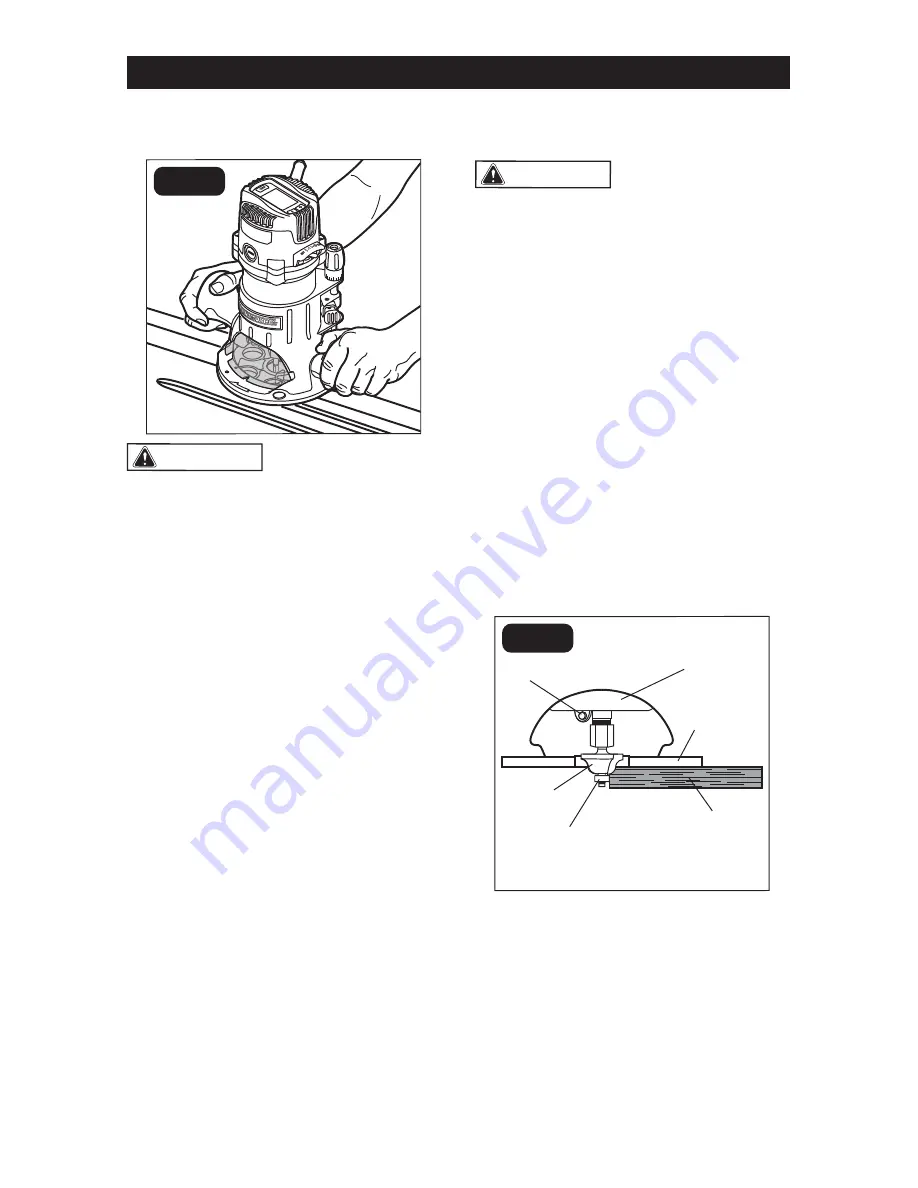

FREEHAND ROUTING WITH THE

FIXED BASE (FIG. 14)

0

3/64

1/64

FIG. 14

WARNING:

Do not use large cutter

bits for freehand routing. Using large

cutter bits when freehand routing could

cause loss of control or create other

hazardous conditions that could result

in personal injury. If using a router table,

large bits should be used for edging only.

When used freehand, the router becomes

a flexible and versatile tool. This flexibility

makes it possible to easily rout signs, relief

sculptures, etc.

When freehand routing:

1. Draw or lay out the pattern on the

workpiece.

2. Choose the appropriate bit.

3. Follow the instructions for INTERNAL

ROUTING, and rout the pattern in two or

more passes. Do not exceed 1/8” depth

of cut in a single pass. This will help

provide better control, as well as serve

as a guide on the next passes.

NOTICE: A core-box bit or V-groove bit is

often used for routing letters and engraving

objects. Straight bits and ball mills are often

used to make relief carvings. Veining bits

are used to carve small, intricate details.

NOTICE: Making a single deep cut is

never advisable. Smaller-diameter bits are

easily broken by too much side thrust and

torque. Larger bits will cause a rough cut

and be difficult to guide and control.

OPERATION

For these reasons, do not exceed 1/8”

depth of cut in a single pass.

WARNING:

Always securely clamp

your workpiece in place, and keep a firm

grip on the router base with both hands at

all times. Failure to do so could result in

loss of control causing possible serious

personal injury.

EDGING WITH A PILOT

BIT (FIG. 15-16)

Arbor-type bits with pilots are excellent for

edge shaping of any workpiece edge that is

either straight or curved at a curvature that

is as great as or greater than the radius of

the bit to be used. The pilot prevents the bit

from making an excessively deep cut; and

holding the pilot firmly in contact with the

workpiece edge throughout prevents the cut

from becoming too shallow.

TOP EDGE SHAPING (FIG. 15)

FIG. 15

Motor

housing

Fixed base

sub-base

Work piece

TOP EDGE SHAPING

Spindle lock

Cutter bit

Pilot

Whenever the workpiece thickness, together

with the desired depth of cut (as adjusted by

the cutting-depth setting) are such that only the

top part of the edge is to be shaped (leaving at

least a 1/16”. thick uncut portion at the bottom),

the pilot can ride against the uncut portion,

which serves to guide it (FIG. 15).