HALOGENATED HYDROCARBON SOLVENTS. For example: Methylene is not chemically compatible with

the aluminum that might be used in many system components. The chemical reaction caused by these

solvents reacting with aluminum can become violent and lead to an equipment explosion. Guns with

stainless steel fluid passages can be used with these solvents. However aluminum is widely used in

other spray application equipment such as material pumps and cups. Make sure they can also be used

safely with these solvents. Read the label or data sheet for the material you intend to spray. If in doubt

as to whether or not a coating or cleaning material is compatible, contact your material supplier.

Spray materials may be harmful if inhaled, or if there is contact with the skin. Adequate exhaust must

be provided to keep the air free of accumulations of toxic materials. Use a mask or respirator whenever

there is a chance of inhaling sprayed materials. The mask must be compatible with the material being

sprayed and its concentration.

SPECIFICATIONS

Fluid Tip Size:

1.6 mm Diameter

Air Inlet:

1/4" (6,35mm) NPS

Air Consumption:

4 CFM (50 PSI)

Capacity of Cup:

7 fl. oz. (207 cc)

Maximum Pressure:

70 PSI

3

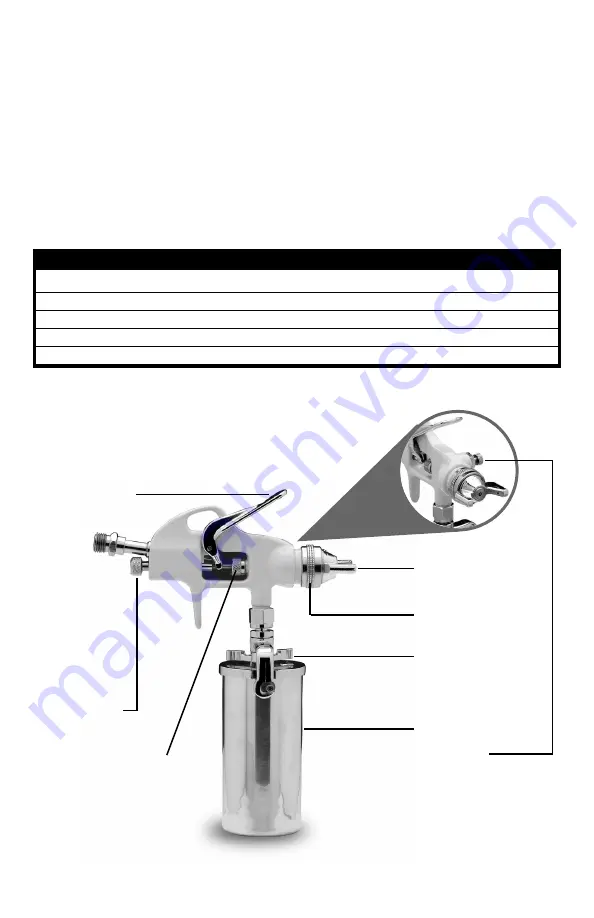

FIGURE 1

Air Nozzle

Air Cap

Container Lock

Container

Spray Pattern

Adjustment Knob

Trigger Handle

Fluid Control

Knob

External Needle Pack

Adjustment (Packing Nut)