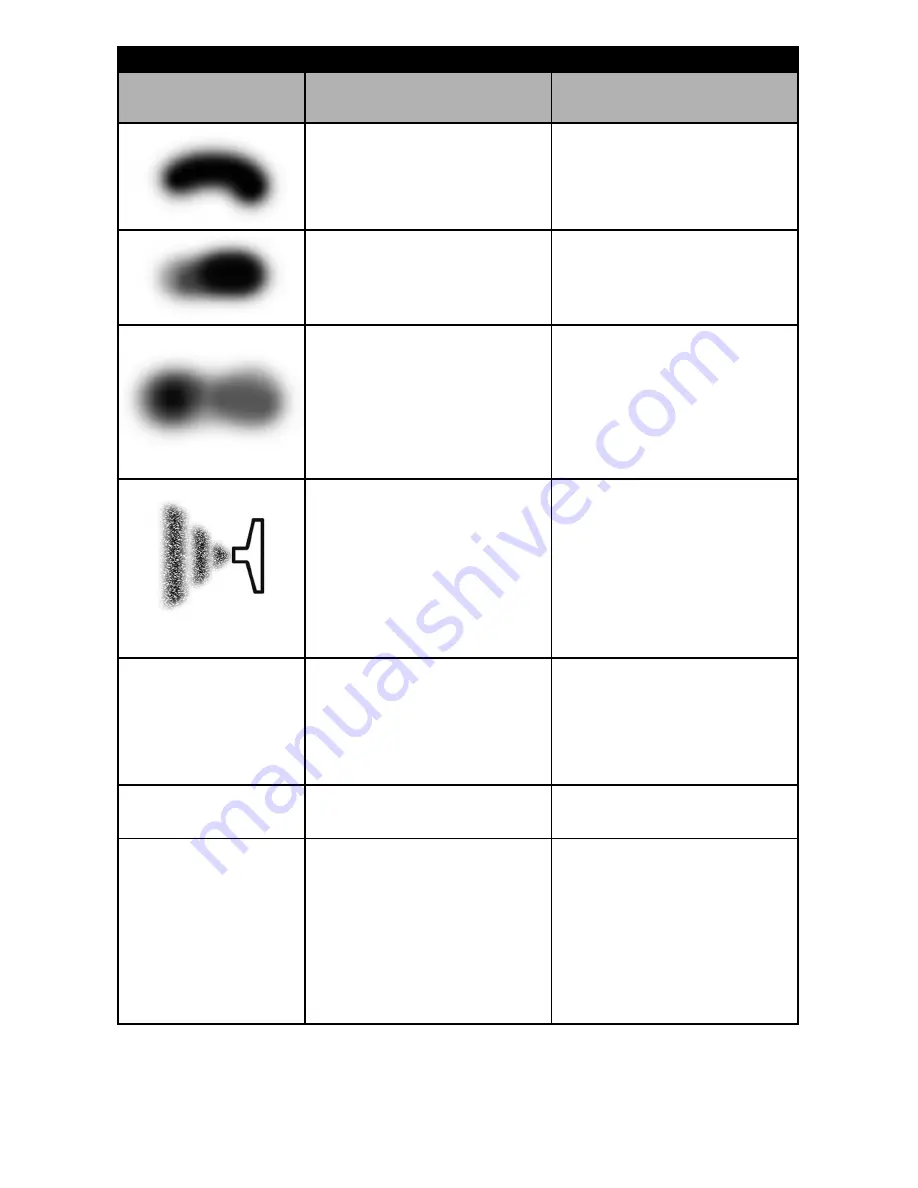

10

SPRAY PATTERN

CONDITION

PROBLEM

SOLUTION

One side of nozzle wing is clogged.

Soak nozzle in solvent to loosen

clogs, then blow air through until

clean. To clean orifices use a

toothpick. Never try and detach

dried material with sharp tool.

a) Loose air nozzle.

b) Material around outside of air

nozzle has dried.

a) Trigger air nozzle.

b) Take off air nozzle and

wipe off fluid tip, using

rag moistened with thinner.

a) Atomization air pressure is set

too high.

b) Trying to spray a thin material

in too wide a pattern.

a) Reduce air pressure.

b) Increase material control by

turning fluid. Control screw

to left, while reducing spray

width by turning spray width

adjustment screw to right.

Spitting

a) Packing around needle valve is

dried out.

b) Fluid nozzle loosely installed or

dirt between nozzle and body.

c) Needle sealing damaged.

a) Back up knurled nut and put

a few drops of machine oil

on packing. Retighten nut.

b) Take off fluid nozzle. Clean rear

of nozzle and seat in gun body.

Replace nozzle and bring in tight

to body.

c) Replace #4 sealing.

Improper spray pattern

a) Gun improperly adjusted.

b) Dirty air cap.

c) Fluid tip obstructed.

d) Sluggish needle.

a) Readjust gun.

Follow instructions carefully.

b) Clean air cap.

c) Clean.

d) Lubricate.

Unable to get round spray

Fan adjustment screw

not seating properly.

Clean or replace.

Will not spray

a) No air pressure at gun.

b) Fluid pressure too low with

internal mix cap and pressure

tank.

c) Fluid control screw not open

enough.

d) Fluid too heavy for suction feed.

a) Check air supply and air lines.

b) Increase fluid pressure at tank.

c) Open fluid control screw.

d) Thin material or change to

pressure feed.

TROUBLESHOOTING