PERSONAL HAZARD WARNINGS

During cleaning and flushing, solvents can be forcefully expelled from fluid and air passages. Some

solvents can cause eye injury. Be sure user and bystanders in the area are wearing impact resistant

eye and face protection. Even small projectiles can injure eyes and cause blindness.

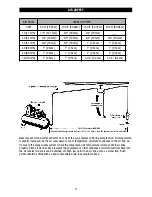

Air under pressure can cause severe injury. Always shut off air supply, drain hose of air pressure and

disconnect tool from air supply when not in use, before changing accessories or when making repairs.

Never direct air at yourself or anyone else. Whipping hoses can cause serious injury. Always check for

damaged or loose hoses and fittings. Never use quick-change couplings at tool. They add weight and

could fail due to vibration. Instead, add a hose whip and connect coupling between air supply and hose

whip, between hose whip and leader hose whip, or between hose whip and leader hose.

DO NOT EXCEED

MAXIMUM AIR PRESSURE OF 90 PSI.

Always use tool a safe distance from other people in work area.

Maintain tools with care. Keep tools clean and oiled for best and safest performance. Follow instructions

for lubricating and changing accessories. Wiping or cleaning rags and other flammable waste materials

must be placed in a tightly closed metal container and disposed of later in the proper fashion.

Do not wear loose or ill-fitting clothing. Remove watches and rings. Do not over reach. Keep proper

footing and balance at all times. Slipping, tripping and falling can be a major cause of serious injury or

death. Be aware of excess hose left on the walking or work surface. Do not abuse hoses or connectors.

Never carry tool by the hose or yank it to disconnect from power supply. Keep hoses from heat, oil

and sharp edges. Check hoses for weak or worn condition before each use, making certain that all

connections are secure.

High sound levels can cause permanent hearing loss. Protect yourself from noise. Noise levels vary with

work surface. Wear ear protectors. When possible secure work with clamps or vise so both hands are

free to operate tool.

Repetitive work motions, awkward positions and exposure vibration can be harmful to hands and

arms. Avoid inhaling dust or handling debris from work processes, which can be harmful to your health.

Operators and maintenance personnel must be physically able to handle the bulk, weight and power of

the tool. This tool is not intended for using in explosive atmospheres and is not insulated for contact with

electric power sources. Solvent and coatings can be highly flammable or combustible especially when

sprayed. Adequate exhaust must be provided to keep air free of accumulations of flammable vapors.

Smoking must never be allowed in the spray area. Fire extinguishing equipmentmust be present in the

spray area. Never spray near sources of ignition such as pilot lights, welders, etc.

2

• FAILURE TO HEED ALL WARNINGS COULD RESULT IN SEVERE PERSONAL OR BYSTANDER INJURY,

EVEN DEATH.

• ONLY USE TOOLS FOR PURPOSE THEY ARE INTENDED FOR.

• YOU MUST WEAR PROTECTIVE EYEWEAR AND SUITABLE RESPIRATORY PROTECTION (OSHA

APPROVED) WHILE SPRAYING OR CLEANING THIS GUN OR ITS ATTACHMENTS.

• NEVER AIM SPRAY GUN AT PEOPLE. SOLVENTS AND THINNERS CAN CAUSE INJURY.

• DO NOT EXCEED RATED OPERATING PRESSURE.

• CAUTION: POTENTIAL FLAMMABILITY OF SPRAYED PAINT, AND AVOID SPRAYING NEAR FLAMES

OR SPARKS.

• USE PAINT MASK/RESPIRATOR WHILE OPERATING PRODUCT.

• USE PRODUCT ONLY IN WELL-VENTILATED AREAS.

• WEAR EAR PROTECTORS.

• HALOGENATED HYDROCARBON SOLVENTS. FOR EXAMPLE: METHYLENE IS NOT CHEMICALLY

COMPATIBLE WITH THE ALUMINUM THAT MIGHT BE USED IN MANY SYSTEM COMPONENTS.