SPRAY GUN HANDLING

Your new spray gun is exceptionally rugged in construction and is built to stand up under hard continuous

use. However, like any other fine precision instrument, its most efficient operation depends on knowledge

of its construction, operation, and maintenance. Properly handled and cared for, it will produce beautiful,

uniform finishing results long after other spray guns have worn out.

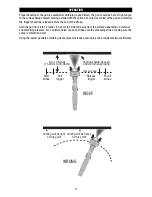

SPRAY PATTERN ADJUSTMENT KNOB:

Turn right for round, left for fan.

FLUID CONTROL KNOB:

Turn right to decrease flow, left to increase.

As width of spray gun is increased, more material must be

allowed to pass through the gun to obtain same coverage

on the increased area.

Spray pattern may be infinitely adjusted

from round to flat.

In normal use, the nozzle wings are horizontal as shown here.

This provides a vertical fan-shaped pattern which gives maximum,

even, material coverage as the gun is moved back and forth parallel

to the surface being finished.

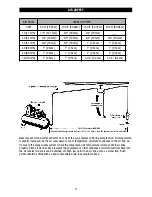

SIPHON SPRAYING

Set atomization pressure at approximately 50 PSI for lacquer and 60 PSI for enamel. Try spray. If it is too

fine, then decrease the air pressure or open fluid control screw. If the spray is too thick, then close the fluid

control screw. Regulate the pattern width and repeat adjustment of spray as needed.

PRESSURE SPRAYING

After selecting correct size fluid, set fluid pressure for the desired flow. Open atomization air and test

spray. If spray is too fine, then reduce air pressure. If spray is too coarse, then raise air pressure. Adjust

pattern width and repeat adjustment of spray.

Keeping fluid control screw in open position will reduce fluid needle wear.

NOTE: To reduce overspray and obtain maximum efficiency, always spray with the lowest possible

atomization air pressure.

5

The spray pattern of the gun is variable

from round to flat with all patterns in between.