CLEANING AND MAINTENANCE

SPRAY GUN

1. Submerge the front end of the gun in solvent just until the fluid connection is covered.

2. Paint that has built up on the gun should be removed using a bristle brush and solvent.

3. Never submerge all of the spray gun in solvent. This will dissolve the lubricant in the leather packing

and on wear surfaces, causing them to dry out and resulting in difficult operation and faster wear. Air

passages in the gun will become clogged with dirty solvent.

4. Using a rag moistened with solvent, wipe down the outside of the gun.

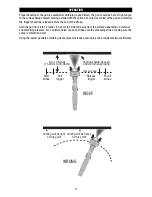

5. Oil gun daily. Use a drop of lightweight machine oil on:

A. External Needle Pack Adjustment (Packing Nut)

B. Trigger Pivot Point

See FIGURE 1 on page 3 for location of above points.

WHEN USED WITH SIPHON CUP

A compatible thinner or solvent should be

siphoned through gun by inserting tube in

open container of that liquid. Trigger gun

repeatedly to flush passageway thoroughly

and to clean tip of needle.

WHEN USED WITH PRESSURE TANK

Shut off air supply to tank and release pressure

on tank. Open vent and loosen air nozzle. Hold

a piece of cloth over the air nozzle and squeeze

trigger. Air will back up through fluid nozzle,

and force fluid out of hose into tank. Next, put

enough thinner into tank to wash hose and gun

thoroughly. Spray thinner through the gun until

it is clean. Attach fluid hose to air line and blow

it out thoroughly to remove all traces of materials

and dry hose.

•

RESPONSIBILITY.

IT SHALL BE THE TOOL OWNER'S RESPONSIBILITY TO ASSURE THAT TOOLS ARE

MAINTAINED IN A SAFE OPERATING CONDITION. IF TOOLS ARE DAMAGED, REMOVE FROM SERVICE

IMMEDIATELY.

•

AUTHORIZED PERSONNEL.

TOOL MAINTENANCE AND REPAIR SHALL BE PERFORMED BY

AUTHORIZED, TRAINED, COMPETENT PERSONNEL. PLEASE CALL OUR CUSTOMER SERVICE AT

1-800-423-3598 FOR INFORMATION.

•

REPAIRS.

TOOLS SHALL BE DISCONNECTED FROM THEIR COMPRESSED AIR SUPPLY BEFORE

REPAIR IS ATTEMPTED. REPAIRS SHALL BE CONSISTENT WITH MANUFACTURER'S RECOMMENDED

PROCEDURES. PLEASE REFER TO CLEANING AND MAINTENANCE OR TROUBLESHOOTING SECTIONS.

•

REPLACEMENT.

TOOLS, HOSES AND FITTINGS SHALL BE REPLACED IF UNSUITABLE FOR SAFE

OPERATION.

8