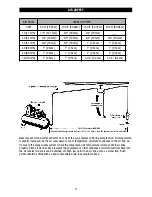

AIR PRESSURE

Oil and water extractor is important.

Achieving a fine spray finish without the use of a good oil and water extractor is virtually impossible.

The extractor eliminates blistering and spotting by keeping air free of oil and water and gives precise

air pressure control at the gun.

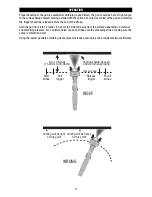

AIR NOZZLE, FLUID NOZZLE, AND NEEDLE ASSEMBLY

1. All nozzles and needles are precision made and should be handled with care.

2. Except as described in #5, do not make any alterations to the gun.

3. To clean nozzles, soak them in solvent to dissolve any dried material. Afterwards, blow the

nozzles clean with air.

4. Do not probe any of the holes in the nozzles with metal instruments. If probing is necessary,

use only a tool that is softer than brass.

5. Adjust the fluid needle valve so when gun is triggered, air flow occurs before fluid flow.

SERVICE

• Tool service must be performed only by qualified repair personnel. Service or maintenance performed

by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may

create a risk of electrical shock or injury.

9

DO NOT USE LUBRICANTS CONTAINING SILICONE.

SILICONE MAY CAUSE DEFECTS IN THE FINISH APPLICATION.

ALL PARTS ON A SPRAY GUN SHOULD BE SCREWED IN BY HAND AT FIRST.

THIS WILL AVOID THE POSSIBILITY OF CROSS THREADING THE PARTS. IF THE PARTS

CANNOT BE TURNED BY HAND EASILY, MAKE SURE YOU HAVE THE CORRECT PARTS,

UNSCREW, REALIGN, AND TRY AGAIN.

NEVER

USE UNDUE FORCE IN MATING PARTS.