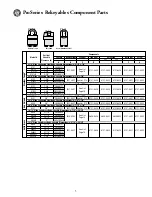

Master Lock keys are coded from bow to tip and with a few exceptions, the increment used

is .0155". Master Lock keys will be encountered with two types of stamping on them.

Both direct and blind codes are stamped on the keys for different products. In the 291 pin

kit you will find the 290-0371 slip gauge for decoding keys. For ProSeries

®

products,

use the top slot in the gauge. Insert the key in the slot at the large end perpendicular to

the gauge. Once inserted, pull the key toward the smaller end of the slot until it stops.

The number stamped on the gauge directly below where the key stops is the cut depth for

that cut position on the key. Repeat the process for each cut position on the key to

determine the actual combination of the key.

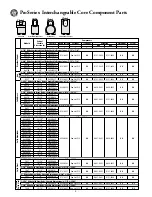

The cylinder being rekeyed may be set to an existing key combination or it may be zero-bitted. In either case, follow the plug

out of the shell and discard the existing pins from the plug. If the cylinder was Master Keyed, also remove any master pins that

may have been retained in the shell. For the combination decoded, select the appropriate length pin from the 291 pinning kit,

and install in the appropriate pin chamber of the plug. Once all pins have been installed, insert the plug into the shell and

check for smoothness of operation. If you note roughness in the operation, check the key to be sure it has been produced to the

bitting specifications on page 20.

M

A S T E R

K

E Y I N G

Most keying system software offers the option of providing a pinning

chart. It is advisable to use that option. If the option is not available,

the following example illustrates the procedure required to determine

the pinning of a master keyed cylinder.

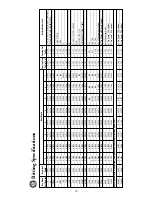

With the example master key combination of 047345 at right, and the

change key combination of 405253, the first step is to figure out the

bottom pins that you must install in the cylinder, then the required master

pins must be determined.

Bottom pins must be selected to allow operation of the shallowest cut

per position in the cylinder for either key. By comparing the two

combinations, select the shallowest cut for each cut position from either

key. In our example we have highlighted the shallowest cut depth,

and you can see that our bottom pins for the cylinder will be 005243.

The master pin sizes are determined by subtracting the shallowest cut

depth from the deepest cut depth for each pin position in the lock.

As noted in the example, the difference is 442112.

From this process, we know that in the first pin chamber we must have

a number zero bottom pin and a number 4 master pin for both keys

to operate. The illustration at the right shows the pinning for the master

keyed cylinder example. Depending upon the size of your key system,

you may or may not require master pinning in all of the pin chambers.

If you find that some cylinders require master pins in different pin

chambers or if different cylinders require different quantities of pin

chambers to have master pins, question the design of the system before

proceeding. Having master pins in different pin chambers may indicate

that the system utilizes a Rotating Constant Method of progression, which

should be verified. Having different quantities of master pins in different

cylinders usually indicates faulty key system design, and you should

recommend that the system be replaced.

Keying

16

0

4 7 3

4

5

4

0 5 2

5

3

Bottom Pins are bold.

0 4 7 3 4 5

4 0 5 2 5 3

4 4 2 1 1 2

Difference equals master pins