MW 8100

PORTABLE WELDING FUME EXTRACTOR

MW 8100

6.

T

ROUBLES AND

C

URES

Make sure that the machine is switched off and disconnected from the

supply mains before carrying out any maintenance or repair procedures.

Make also sure that these procedures can not cause any damages to things

or people.

Always apply to Qualified Personnel.

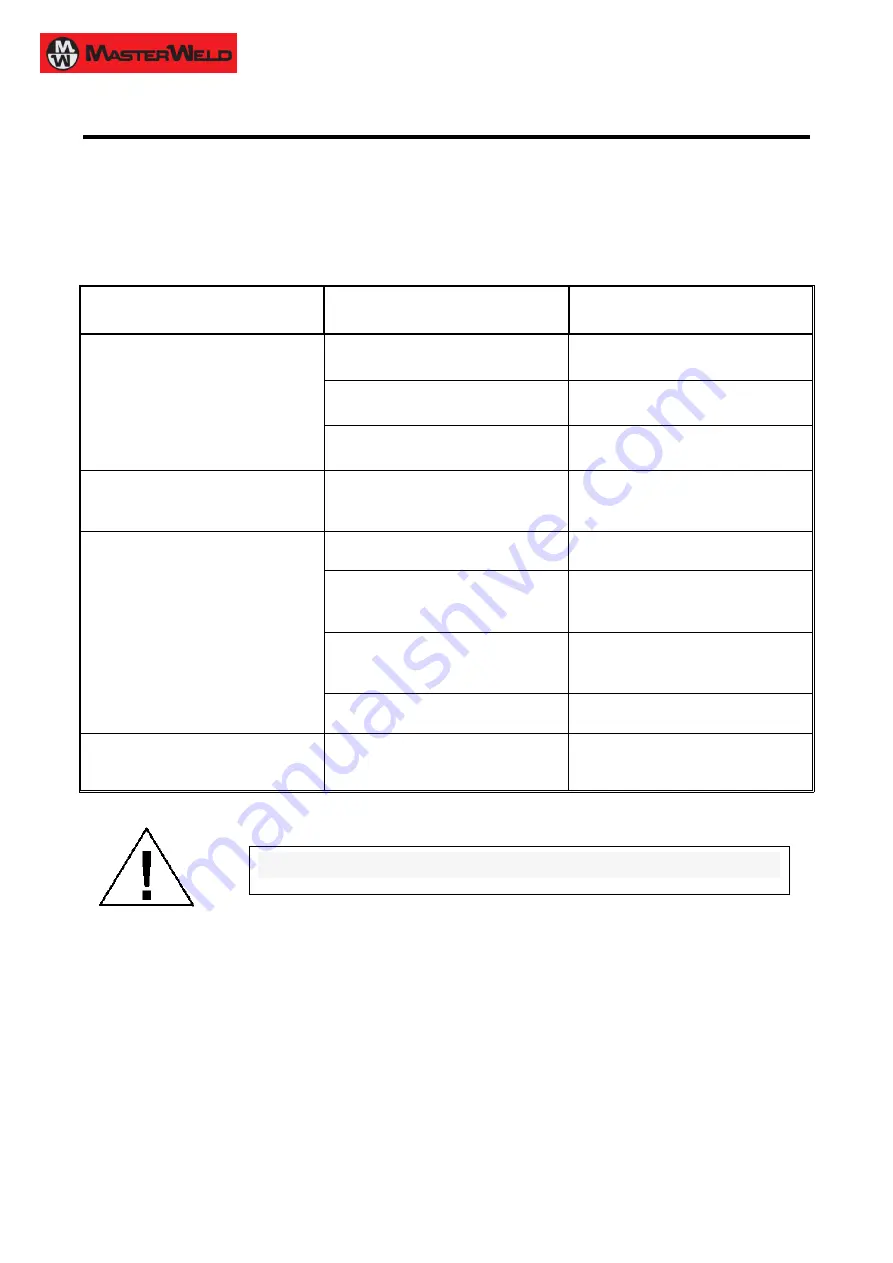

Troubles

Causes

Cures

Machine fails to start up

The Fuse has burnt out

Check its state (it is placed near

the star up button - picture 3)

Too low voltage

Check the supply mains voltage

The electric motor is mis-working

Contact our After-Sale Service or

professionally qualified staff

The emitted air is not purified

enough

Inefficacious action of filters

Check their state and replace them

(ref. to chapter 5

M

AINTENANCE

)

The machine does not develop a

sufficient aspirating capacity

Filters are clogged and dirty

Check their state and replace them

(ref. to chapter.

5

M

AINTENANCE

)

Physical obstructions and/or

blockages

Check whether there are any

foreign bodies inside the hose.

Take them away

The hose is broken or damaged

Check its state and if it’s damaged

replace it.

The electric motor is not working

Contact our After-Sale Service or

professionally qualified staff

Fuses of main electric system burn

out and/or differential relay device

-ground fault interrupter trips

Short circuit (in electric motor)

Contact our Technical Service or

professionally qualified staff to

carry out a more precise check.

ALWAYS CONSULT A QUALIFIED PERSONNEL