www.masterweld.co.uk

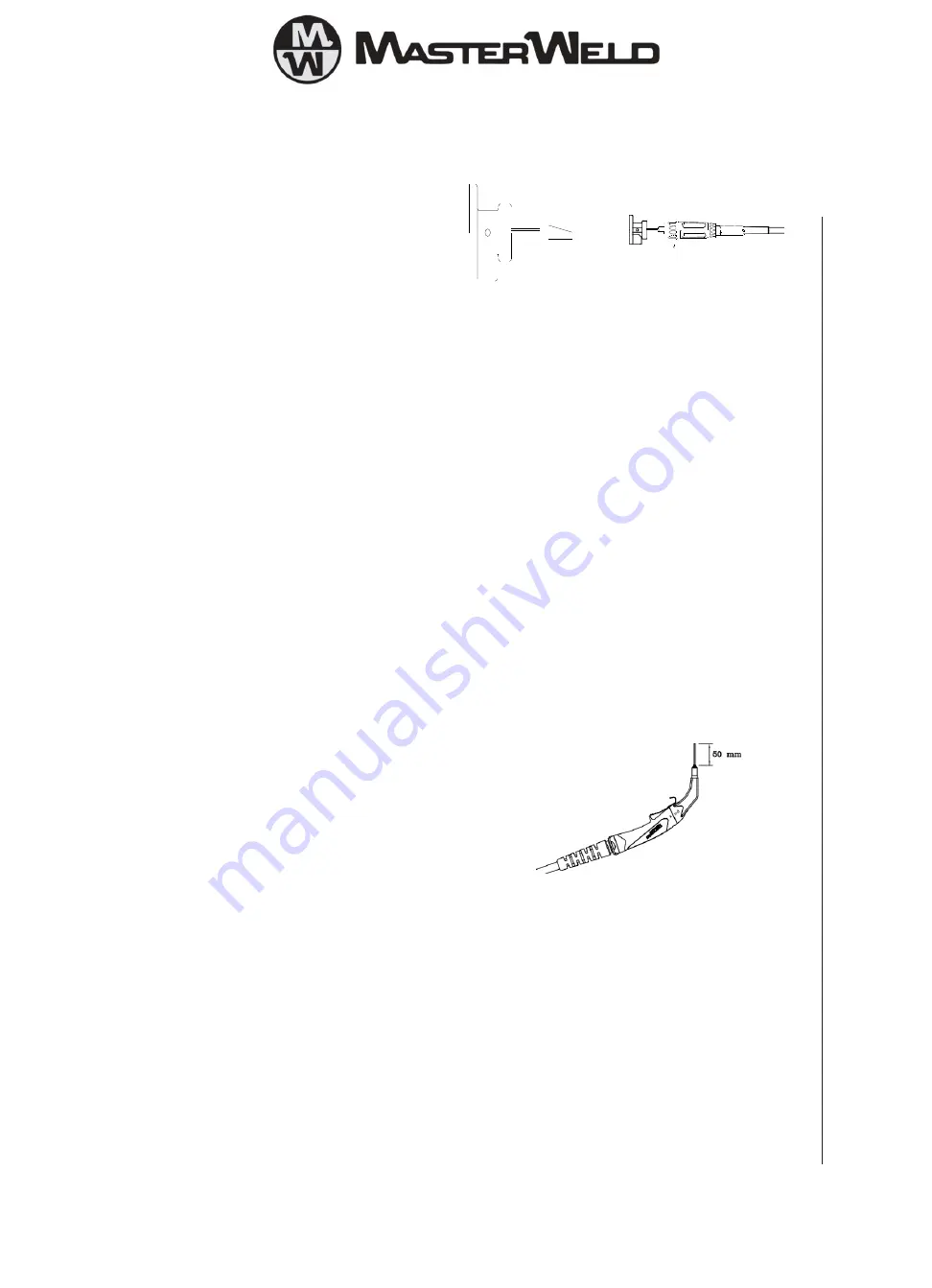

Fig 1

5.11 Torch Installation

•

Insert the Euro connector of the welding torch into the Euro

socket and screw tight with the hand nut.

•

Fit the coolant hoses to the appropriate quick couplings: red

(coolant back flow) and blue (coolant supply).

Wire feed

Opening the door of the wire feeder drive

CAUTION

The door of the feed system must be opened for the following

operations. The door must be closed again before starting work.

Loading the wire to the feed unit

CAUTION

Risk of injury due to moving parts!

Wire feeders are equipped with moving parts that can trap hands,

hair, clothes or tools and thus injure people!

•

Do not handle rotating or moving parts or drive parts by hand!

•

Keep the protective covers closed during operation! Risk of injury

due to uncontrolled welding wire!

The welding wire can be feeding at high speed and can get out of

control and injure people in the case of improper or incomplete wire

feeding!

•

Ensure full wire delivery from the wire coil to the welding torch

before connecting to the mains!

•

If the welding torch is not installed, unscrew the rollers of the wire

feeder!

•

Check the wire delivery at regular intervals!

•

Keep all body covers and protective covers closed during

operation!

Risk of injury due to welding wire feeding from the welding torch!

The welding wire can overflow the welding torch with a high speed

and injure face and eyes with body parts!

•

Never point the welding torch to your body and to the bodies of

others!

ATTENTION

The wear on the wire feed rollers increases due to unsuitable roller

pressure!

•

In the setting nuts of the pressurised pressure units, it must be

adjusted so that the wire electrode is stopped, but only when the

wire feed is blocked!

•

Adjust the press pressure of the front rollers (when viewed in the

push direction) higher!

•

The transmission speed can be infinitely adjustable by pressing

the wire feed button and also by rotating the wire feed speed

rotary knob. The selected feed rate is shown on the left display of

the wire feed unit.

•

Extend the torch straight while loading wire .

Your MasterWeld MIG/MAG Welding Torch has been supplied

ready to weld. It has been supplied with the standard consumables

denoted in the product brochure.

To connect the torch to the power source:-

1. Remove the tip adaptor and contact tip

2. Inch the wire from the exit of the wire guide on the feed unit

as Figure 1. Ensure that it does not short out on any machine

panels.

Fig 2

3. Carefully slide the electrode wire into the torch liner and slowly

locate the torch gun plug body into the feed unit central connector

and tighten the gun plug nut as Figure 2

NOTE:- To aid the initial location of a new torch and to prevent

damage to the gas nipple O Ring a very light application of

grease to the O Ring is beneficial.

4. Keeping the torch as straight as possible, use the power source

inch facility or torch trigger to feed the electrode wire 50mm from

the end of the liner conduit.

5. Once the electrode wire has stopped, refit the tip adaptor,

diffuser, contact tip and gas nozzle.

6. Trim the electrode wire to within 5mm of the face of the nozzle,

this will facilitate jolt free arc initiation.

7. Press the gas purge button and check the gas flow is adequate

for your application.

8. An inexpensive flow meter is available from MasterWeld

9. If you are setting a water-cooled torch ensure you have the

recommended water flow rate.

NOTE:- It is essential to ensure adequate flow of clean, cool

water to prevent irreparable torch failure, a minimum of 1.2 l/

min is recommended.

Note.

Water flows into the torch through the blue hose. The blue

hose delivers cold water directly to the prime source of heat, the

swan neck and consumable. The re circulated water is then passed

through the torch power cable to cool the power cable as it is

returned to the cooler through the red water return lead.

Ensure all air is removed from the water cooling circuit before

welding.

5.12 Work Return Lead Connection

Insert the work return lead connector into the receptacle on the front

panel of the machine and twist it clockwise until tightly secured.

Connect the earth clamp to the work piece as close as possible to

the point to be welded and ensure that a good electrical connection

is created to bare metal.

5.13 Shielding Gas Connection

1. Using the gas hose supplied connect the hose to the gas inlet

connection on the rear of the machine and tighten it with a

spanner.

2. Connect the opposite end of the gas hose to the output

connection of a gas regulator capable of supplying the correct

gas flow for the welding operation.

NOTE:- If the gas cylinder is to be stored on the back of

the machine ensure it is secured using the retention chain

provided.

11