12 - ENG

200-2835

Copyright © 2011 MAT Industries, LLC

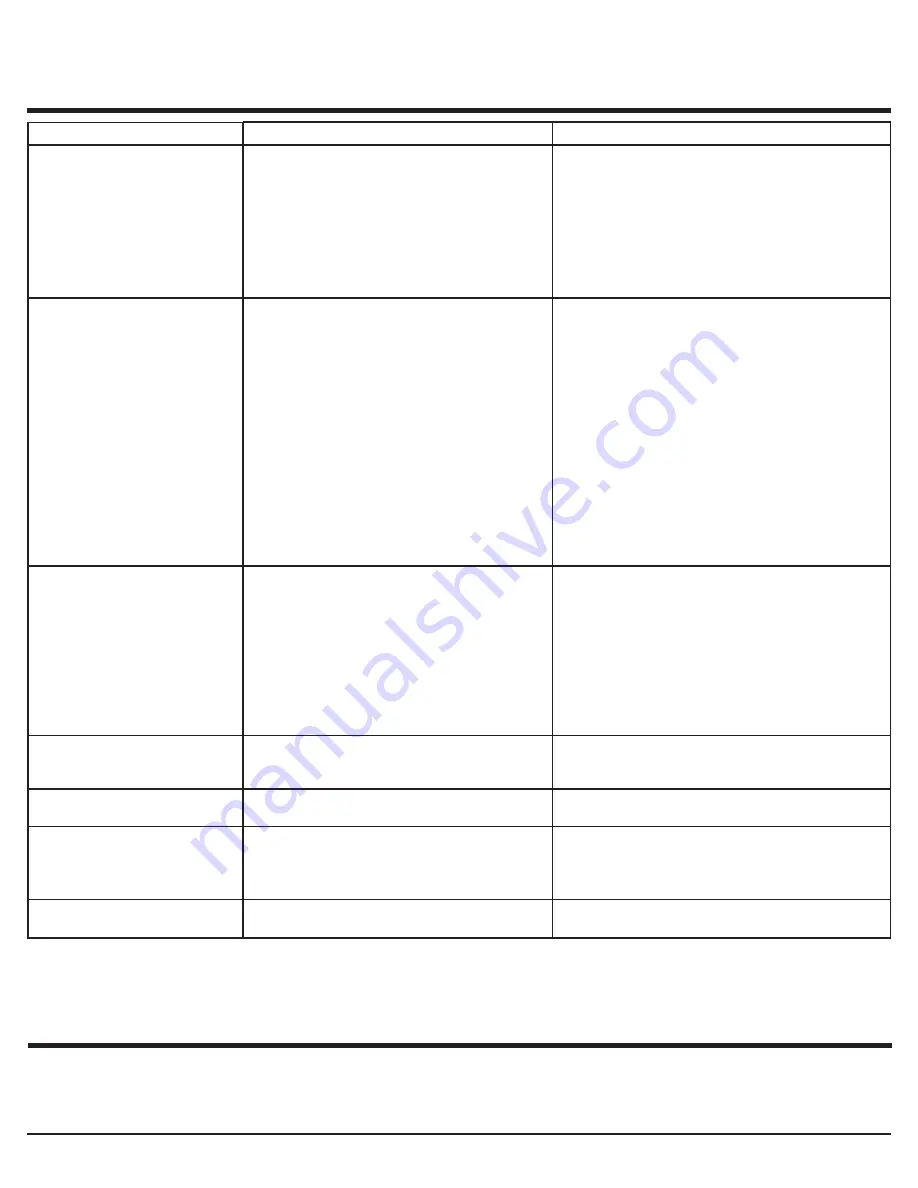

TROUBLESHOOTING GUIDE

• SAVE ALL INSTRUCTIONS

Problem

Cause

Correction

Engine will not start (see Engine

Manual for further engine trouble-

shooting)

1. No fuel

2. Pressure builds up after two pulls on the recoil starter

or after initial use.

3. Choke lever in the “No Choke” position.

4. Spark plug wire not attached.

5. Engine ON/OFF switch in OFF position.

6. Choke lever in the “Choke” position on a “hot” engine

or an engine that has been exposed to thermal heat for

a long period of time.

1. Add fuel.

2. Squeeze gun trigger to relieve pressure.

3. Move choke to the “Choke” position.

4. Attach spark plug wire.

5. Place engine ON/OFF switch in ON position.

6. Move choke to the “No Choke” position.

No or low pressure (initial use)

1. High pressure nozzle is not installed.

2. Low water supply.

3. Leak at high pressure hose fi tting.

4. Nozzle obstructed.

5. Water fi lter screen clogged.

6. Air in hose.

7. Choke lever in the “Choke” position.

8. High pressure hose is too long.

1. See How to Use Spray Wand instructions in the Operation

Section.

2. Water supply must be at least 5 GPM @ 20 PSI.

3. Repair leak. Apply sealant tape if necessary.

4. See Nozzle Cleaning instructions in the Maintenance sec-

tion.

5. Remove and clean fi lter.

6. Turn off the engine, then the water source. Disconnect

the water source from the pump inlet and turn the water

source on to remove all air from hose. When there is a

steady stream of water present, turn water source off. Re-

connect water source to pump inlet and turn on water source.

Squeeze trigger to remove remaining water.

7. Move choke to the “No Choke” position.

8. Use high pressure hose under 100 feet.

Will not draw chemicals

1. Low pressure soap nozzle not installed.

2. Chemical fi lter clogged.

3. Chemical screen not in cleaning solution.

4. Chemical too thick.

5. Pressure hose too long.

6. Chemical build up in chemical injector.

1. See How to Use Spray Wand paragraph in the Operation

Section.

2. Clean fi lter.

3. Make sure end of chemical hose is fully submerged into

cleaning solution.

4. Dilute chemical. Chemical should be in the same consis-

tency as water.

5. Lengthen water supply hose instead of high pressure

hose.

6. Have parts cleaned or replaced by AWSC.

No or low pressure (after period of

normal use)

1. Worn seal or packing.

2. Worn or obstructed valves.

3. Worn unloader piston.

1. Have replaced by AWSC.

2. Have replaced by AWSC.

3. Have replaced by AWSC.

Water leaking at gun/spray wand

connection

1. Worn or broken O-ring.

2. Loose hose connection.

1. Check and replace.

2. Tighten.

Water leaking at pump

1. Loose connections.

2. Piston packing worn.

3. Worn or broken O-rings.

4. Pump head or tubes damaged from freezing.

1. Tighten.

2. Have replaced by AWSC.

3. Have replaced by AWSC.

4. Have replaced by AWSC.

Pump Pulsates

1. Nozzle obstructed.

1. See Nozzle Cleaning paragraph in the Maintenance sec-

tion for the correct procedure.

AWSC

= Authorized Warranty Service Center

REPAIRS

• SAVE ALL INSTRUCTIONS

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment should be performed by an Authorized Warranty Service

Center. Always use identical replacement parts. For the location of the nearest Authorized Warranty Service Center call 1-888-895-4549 or visit

our website www.powermate.com.