6 - ENG

200-2835

Copyright © 2011 MAT Industries, LLC

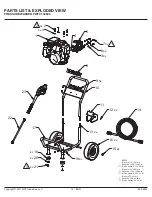

ASSEMBLY INSTRUCTIONS

• SAVE ALL INSTRUCTIONS

1. Locate and remove all loose parts from the carton. (Fig. 1)

2. Cut four corners of the carton from top and bottom and lay the panels fl at. (Fig. 2)

3. Install the handle (A) by centering it over the frame, push in the pins (B) slightly and

push down to lock in place.

4. Roll the unit off the carton and discard carton.

5. Attach the hose hook (C) to the handle (A) by lining up the 2 holes in the base

with the studs on back of the handle, then thread the 2 nuts (D) onto the studs as

shown in Fig. 3 and tighten using a 3/8” wrench or socket, or adjustable open-

ended wrench (i.e. crescent wrench). Insert the 5 nozzle tips into the grommets on

the

panel.

6. Connect high-pressure hose to pump outlet (E). Tighten securely. (Fig. 3)

7. Connect wand to gun. Tighten securely. (Fig. 4)

8. Attach high-pressure hose to gun. Tighten securely. (Fig. 5)

C A U T I O N

There is a shipping plug inserted in oil plug when pump is

shipped from the factory. The shipping plug prevents any oil from leaking out of

the pump in shipping. The shipping plug must be removed before the pressure

washer is operated. To remove the shipping plug, pull it out directly.

NOTE: The pump is supplied with the correct amount of oil and does not re-

quire further service.

W A R N I N G

RISK OF BURSTING.

Use a tire pressure gauge to check the

tires pressure before each use and while infl ating tires; see the tire sidewall for the

correct tire pressure.

NOTE:

Air tanks, compressors and similar equipment used to infl ate tires can fi ll small

tires similar to these very rapidly. Adjust pressure regulator on air supply to no more

than the rating of the tire pressure. Add air in small increments and frequently use the

tire gauge to prevent over infl ation.

FIG. 5

FIG. 2

FIG. 1

B

A

C

D

E

FIG. 3

FIG. 4