52 TO REMOVE AND REPLACE THE OIL PUMP PLUNGER

Remove :—

Lower end of rocker box oil feed pipe by unscrewing union nut.

Both oil pump end caps.

Oil pump plunger guide screw. (See Illustration 13).

Oil pump plunger, by pushing at from and extracting from rear end of its housing.

Replace by :—

Reversing above procedure.

Note :—

Remember there is a paper washer under each oil pump end cap and, when

fitting a new paper washer to the front cap, ensure the oil passage in the cap is not

obstructed by the paper washer.

Make certain that the guide screw is correctly located in its groove (cut in the

plunger) before tightening down otherwise serious damage will result when

revolving engine.

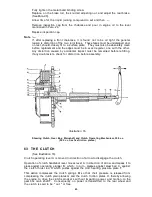

Illustration

13

The rotating oil pump plunger, is here shown partially withdrawn, together

with the guide screw which registers in the plunger profiled groove, thereby

providing the reciprocating movement.

(By courtesy of " Motor Cycling ")

1

2

3

4

5

6

7

DOWEL PEG, LOCATING TIMING GEAR

COVER.

BUSH, FOR INLET CAMSHAFT.

PLUNGER, FOR OIL PUMP.

BOLT, FIXING REAR END CAP.

BOLT, FIXING REAR END CAP.

REAR END CAP, FOR OIL PUMP.

TAPPED HOLE, FOR PIPE RETURNING

OIL TO OIL TANK.

8

9

10

11

12

13

14

TAPPED HOLE, FOR PIPE FEEDING OIL TO

OIL PUMP.

TAPPED HOLE, TO ACCOMMODATE

CRANKCASE DRAIN PLUG.

CRANKCASE. TlMING SIDE.

GUIDE SCREW, FOR OIL PUMP PLUNGER.

PLUG SCREW, FOR OIL PASSAGE.

PLUG SCREW, FOR OIL PASSAGE.

BUSH, FOR TIMING SIDE FLYWHEEL

AXLE.

34

Summary of Contents for 46/G3L 1946

Page 2: ......

Page 54: ...Illustration 19 52 ...

Page 89: ...Illustration 36 Wiring Diagram Pictorial 87 ...

Page 91: ......

Page 92: ......