Screw into the hub shell the adjusting ring (5 Illustration 22).

Screw the lock nut (6 Illustration 22) on the adjusting ring.

Adjust hub bearings by the method described in Para. 83.

Inject two fluid ounces of grease into the hub shell. (Through grease nipple in

hub barrel). (More than this quantity may result in brake inefficiency).

Re-fit brake cover plate with shoes, etc. and, if a rear wheel, also re-fit the speedo-

meter drive gear box and the central spindle.

The wheel is than ready for fitting to machine.

Note :—

In the case of the front brake cover plate it is most important this is correctly

positioned.

It is retained to the front wheel spindle by an inside nut (part number 40-G12M-

H47), and an outside nut (part number 40-G12M-H46). Between the inside

nut and the brake cover plate is a locating washer (part number 40-G12M-B100).

The inside nut should be positioned so that, when the locating washer is placed

next to it, the outside face of the washer is z " proud of the outer edge of the

brake drum. (Tested by placing a straight edge across the edge of the brake drum).

86 BRAKE SHOES

The front and rear brake shoes, springs and expanders are interchangeable. The two

shoes in each brake are

NOT

identical, they are " handed."

One end of each shoe bears on a fulcrum fixed in the brake cover plate. The other end

accommodates a detachable thrust collar. (See Para. 87).

87 BRAKE SHOE ADJUSTMENT

Brake adjustment, to compensate for lining wear, is normally made by means of a finger

adjuster on the rear brake rod and a cable adjuster for the front brake cable.

After a very considerable mileage this continual adjustment causes the brake expander

to occupy a position whereby the available leverage is considerably reduced and

consequently the brake loses efficiency. (See Paras. 90 and 91 and Illustrations 25 and 26).

To overcome this, the brake shoes have adjustable thrust collars. These have machined

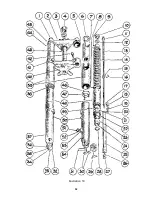

slots of three varying depths (See Illustration 23).

Adjustment is obtained by removing the collars and turning them. so that the next

shallower slots are engaged with the shoes upon replacement on the shoes.

The thrust collars on each pair of shoes must be engaged by the same depth slots, so

as to match the shoes.

When wear on the brake linings is taken up in this manner it is then necessary to con-

siderably unscrew the adjusting nuts on the rear brake rod, or screw in the cable adjuster

of the front brake cable, and then to adjust the brake as described in Paras. 90 and 91.

When a brake cover plate and brake shoe assembly has been disturbed, it is advisable,

upon re-assembly, to centralise the brake shoes in the brake drum to ensure equal shoe

pressure. This is best done before re-fitting the wheel to the machine (front wheel

only) and before fully tightening the spindle nut retaining the brake cover plate to the

wheel spindle. (If rear wheel, do in situ).

63

Summary of Contents for 46/G3L 1946

Page 2: ......

Page 54: ...Illustration 19 52 ...

Page 89: ...Illustration 36 Wiring Diagram Pictorial 87 ...

Page 91: ......

Page 92: ......