7

§5 Maintenance

5.1 Cutting Torch Maintenance

Plasma cutting torches use ionized air (plasma) as the arc that “melts” the metal and is pushed away by

the compressed air. This

plasma arc exceeds 50,000°F (28,000°C)

when it is pushed through

the .030”-.040” (0.8-1.0mm) hole in the berylium copper cutting tip. Considering these extreme temperatures,

it is easy to understand the

need to replace tips & electrodes, as they become worn

, and to check that all

cooling air ports are clear to allow maximum air flow.

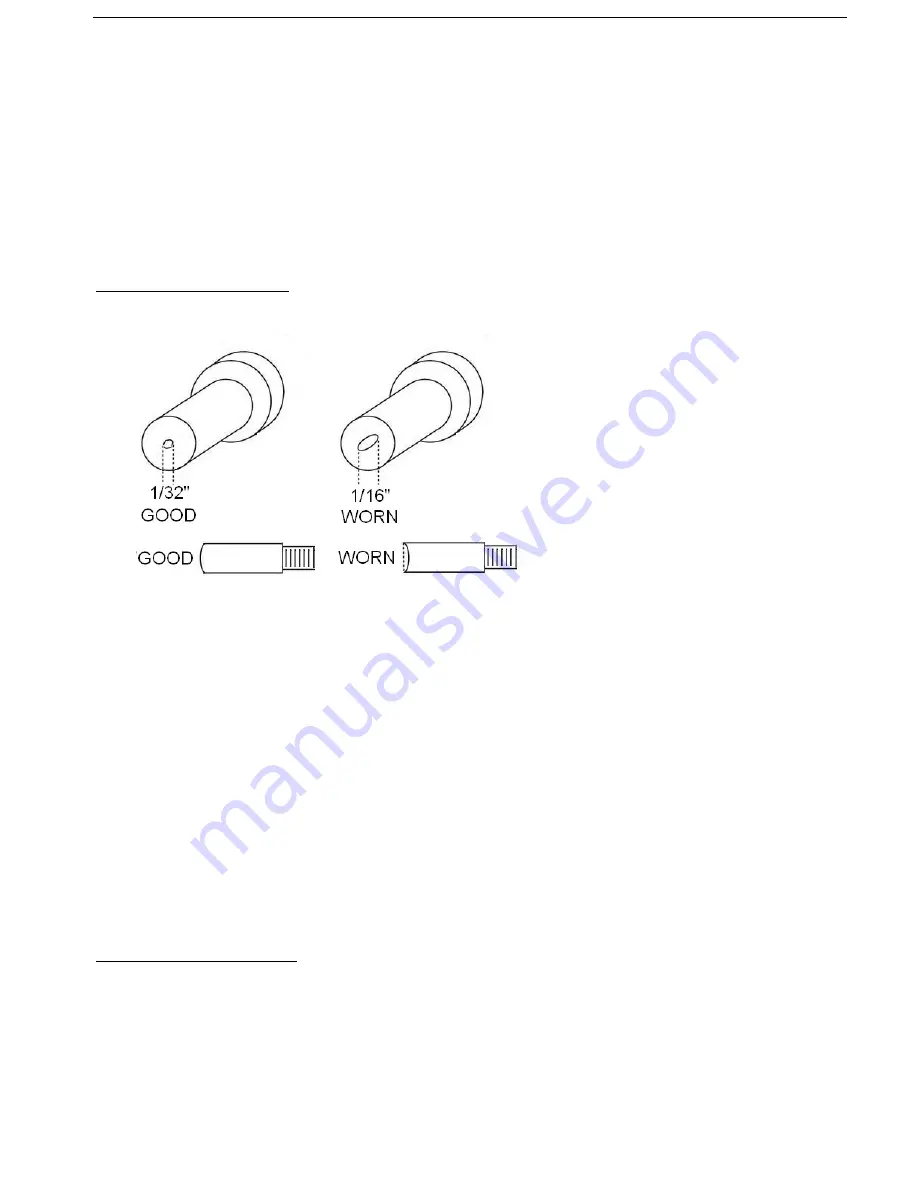

Changing Tip & Electrodes: When reduced cutting performance is observed by the operator, worn tips and

electrodes must be replaced. A simple visual inspection will determine need for replacement.

To replace tips & electrode, complete the following steps:

1) Turn power switch to OFF position, making certain power pilot LED on panel is OFF (wait 5 secs.)

2) Move torch head to clean work benchtop area and, with tip pointing up, remove shield cap.

3) Remove cutting tip and swirl ring by lifting off electrode and place both on bench.

4) Locate electrode wrench and remove electrode by rotating counter-clockwise (RH thread).

5) Inspect torch head for clogged air ports or damage.

6) Replace elctrode with new part and

tighten with wrench

. It is important to secure with wrench as

electrode transfers very high DC current at vert high temperatures.

A loose electrode will damage

the torch head

.

7) Inspect the swirl ring for any damage and replace if necessary.

8) Install the new cutting tip making sure to align with the step in the swirl ring.

9) Inspect the shield cap, making certain no melted outer covering is blocking cooling air ports. If shield

cap is burned or cover is melted, replace.

10) Reinstall shield cap, making certain it is securely turned down to the base making contact with

safety pins located in handle.

Inspecting Cables & Hoses: Upon completing torch consumable replacement, check all power cables,

hoses and the regulator glass bowl (empty water if necessary) to make certain there is no damage. In the

event of damaged insualtion on a cable, repair with proper electrical tape or shrink tubing or repalce with

new assembly.

Summary of Contents for MA48

Page 12: ...5 4 Electrical principle drawing ...

Page 13: ...5 5 PCA48 Parts Drawing ...