FRENCH

Page 6

WARNING

2003041-14

MNTS8

HAND PISTOL RIVET NUT KIT

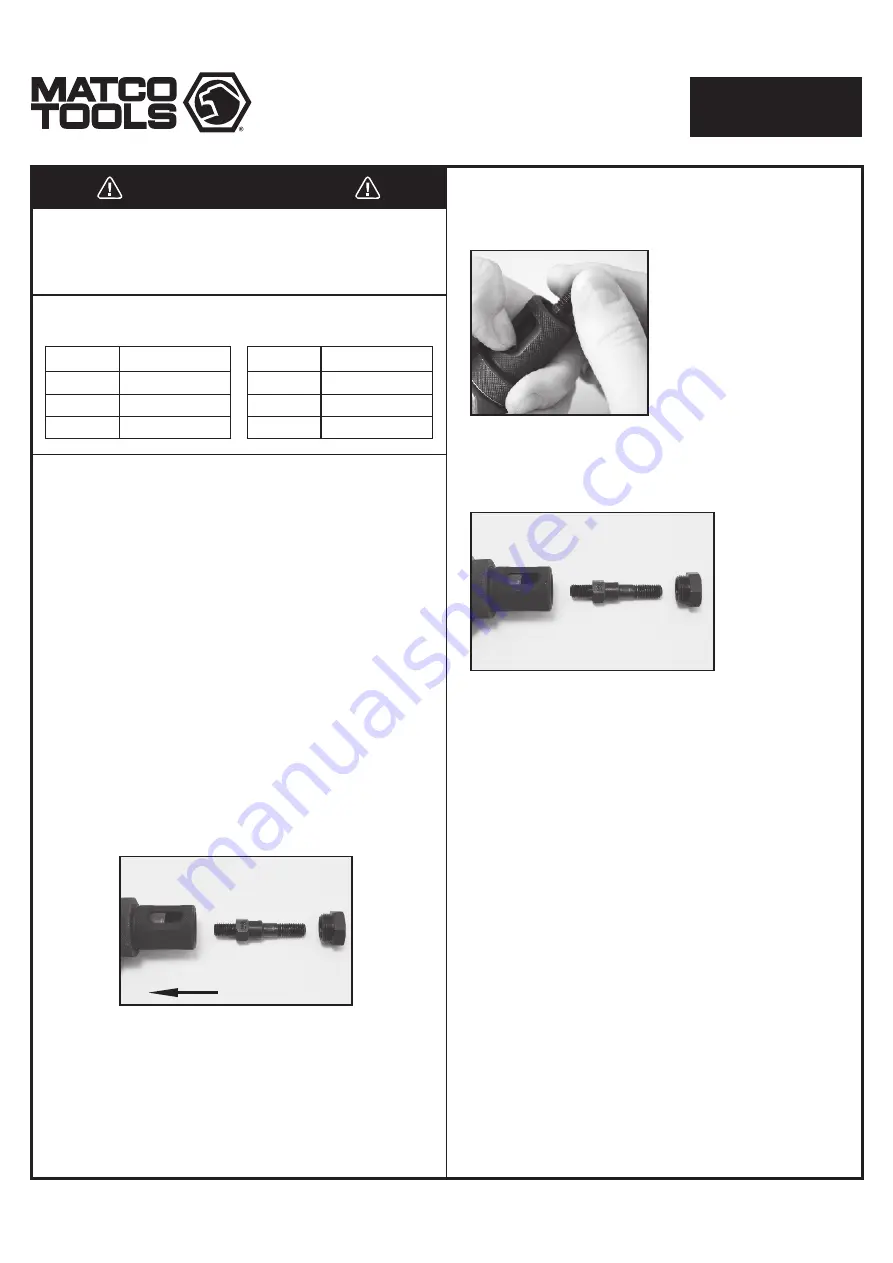

1. Remove and install the mandrel and nosepieces. Always

keep the matched mandrel/nosepiece sets together.

2. Remove nosepiece from #16 sleeve by unthreading the

nose piece counterclockwise. This can be done either by

hand or with the provided wrench if too tight to do so.

OPERATING INSTRUCTIONS:

1. Choose the rivet nut size to be installed.

2. Install the correct size mandrel/nosepiece for the rivet nut

to be installed. See photos and instructions for changing

the mandrel/nosepiece and adjustment.

3. Drill a hole in the work product the same size or slightly

larger than the outside diameter of the rivet nut to be

installed.

4. To install the rivet nut, open the handles outward as far

as possible and thread the rivet nut clockwise onto the

mandrel until reaching the nosepiece.

5. Insert the rivet nut fastened to the riveter into the

pre-drilled hole until flush with the work product, and

pull handles inward to secure the rivet nut into the hole.

If the rivet nut is loose in the hole, open the handles

outward, turn #10 knob clockwise, and pull handles

inward until the rivet nut is secure in the hole. Repeat as

necessary until the rivet nut is secure in the hole. See

adjustment instructions if necessary.

6. Turn the #10 knob counterclockwise until the mandrel is

removed from the rivet nut. The rivet nut installation is

complete if the rivet nut is secure from movement in the

hole.

CHANGING MANDREL/

NOSEPIECE INSTRUCTIONS:

Assembly direction

DRILL SIZE GUIDE:

Nut Size

M4

M5

M6

Drill Size

6mm (7/32")

7mm (9/32")

9mm (3/8")

Nut Size

8-32

10-24

1/4-20

Drill Size

6mm (7/32")

7mm (9/32")

9mm (3/8")

SAE

Metric

WARNING

Always wear ANSI approved safety goggles when using this

product (users and bystanders). Failure to read and follow

all warnings and operating instructions may result in

damages and serious injuries or death.

3. Using your thumbnail or tool, press down to depress the

#15 inner hexagonal sleeve that sits within the #16 outer

sleeve. This should expose the lower hex portion of the

mandrel.

4. Unthread the mandrel by hand to remove it from the

sleeve. Once the mandrel has been threaded out far

enough to clear the #15 hex sleeve you may release

tension on this sleeve collar.

5. Choose the correct mandrel/nosepiece to be installed.

6. Thread the new mandrel into the tool by hand until it

approaches the #15 hex sleeve and fully depress this

sleeve to allow the mandrel to be threaded further until it

stops. The mandrel does not need to be torqued. Release

the hex sleeve and allow it to fully reengage the mandrel.

If the mandrel and hex sleeve do not initially align, rotate

the #10 knob while holding onto the mandrel until it clicks

up and reengages.

7. Thread the matching nose piece into the #16 by hand.

Torqueing the nose piece is optional.