RL-450

4

Rev. 08/06/03

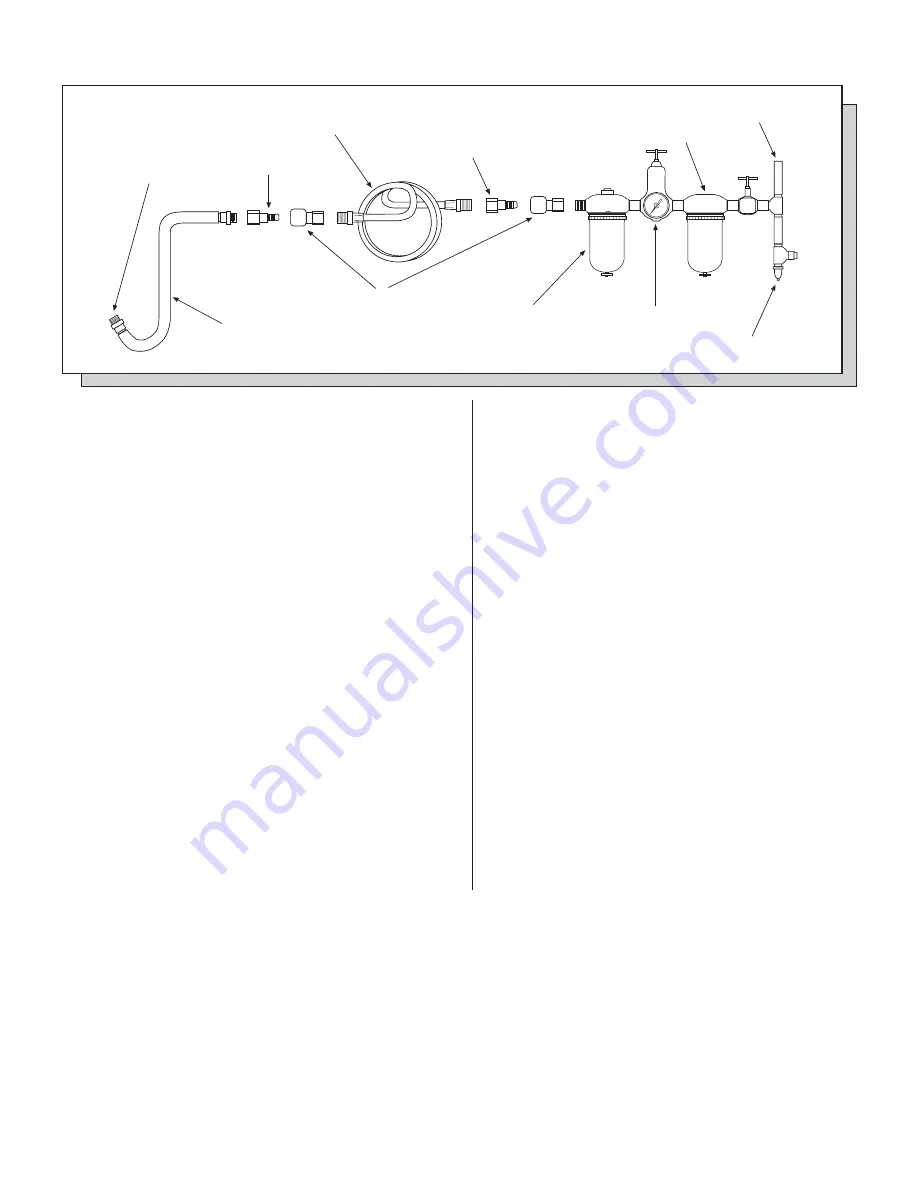

Nipple

Leader Hose

Whip Hose

Nipple

Filter

Air Supply

Regulator

Quick Coupler

Oiler

Drain Daily

Do Not Install

Quick Coupling

Here

Operating Instructions • Warning Information • Parts Breakdown

Operation...

• Always use the recommended wheel guard to prevent injury

from broken grinding wheel parts. If a guard has withstood a

wheel breakage, discontinue its use and replace it with a new

guard. It may be damaged. Position the guard between the

grinding wheel and the operator. Use barriers to protect others

from wheel fragments and grinding sparks.

• Always wear impact-resistant eye and face protection when in-

volved in the operation of this tool. Even small projectiles can

injure eyes and cause blindness. A grinding wheel that bursts

can cause very serious injury. Daily measure the air grinder

speed with a tachometer to make sure it's not greater than the

RPM marked on the grinding wheel. Never use a grinding wheel

marked with a speed lower than the air grinder speed.

• Before grinding, test grinding wheel by briefly running the tool

at full throttle. Be sure to use a barrier (such as under a heavy

work table) to stop any possible broken wheel parts.

To Assemble Grinding Discs:

1. Use stop spanner (#41) to hold gear shaft (#11).

2. Screw on disc nut (#4) with shoulder side facing tool. Tighten.

3. Attach grinding disc wheel.

4. Screw on other disc nut, shoulder side facing tool.

Secure tightly!

Air Supply...

Tools of this class operate on a wide range of air pressures. It is

recommended that air pressure of these tools measure 90 PSI at the

tool while running free. Higher pressure (over 90 psig; 6.2 bar) raises

performance beyond the rated capacity of the tool which will shorten

the tool’s life because of faster wear and could cause injury.

Always use clean, dry air. Dust, corrosive fumes and/or water in the

air line will cause damage to the tool. Drain the air tank daily. Clean

the air inlet filter screen on at least a weekly schedule. The recom-

mended hookup procedure can be viewed in the above figure.

The air inlet used for connecting air supply, has standard 1/4" NPT.

Line pressure should be increased to compensate for unusually long

air hoses (over 25 feet). Minimum hose diameter should be 3/8" I.D.

and fittings should have the same inside dimensions and be

tightly secured.

Lubrication...

Lubricate the air motor daily with quality motor oil. If no air line oiler

is used, run a teaspoon of oil through the tool. The oil can be squirted

into the tool air inlet or into the hose at the nearest connection to the

air supply, then run the tool. The amount of oil to be used is 1 ounce.

Overfilling will cause a reduction in the power of the tool.

MATCO TOOLS™ 1 YEAR LIMITED WARRANTY FOR AIR TOOLS

Matco warrants its air tools for a period of 1 year to the consumer. We will repair any air tool covered under this warranty which proves to

be defective in material or workmanship during the warranty period. In order to have your tool repaired, return the tool to any Matco

Authorized Warranty Center, freight prepaid. Please include a copy of your proof of purchase and a brief description of the problem. The

tool will be inspected and if any part or parts are found to be defective in material or workmanship, they will be repaired free of charge and

the repaired tool will be returned to you freight prepaid.

This warranty gives you specific rights. You may also have other rights which vary from state to state.

The foregoing obligation is Matco's sole liability under this or any implied warranty and under no circumstances shall Matco be liable for

any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages so the above limitation or exclusion may

not apply to you.