ll. SAFETY GUIDE:

Dimensions:

Weight:

Hex Shank Size:

Riveting Capability:

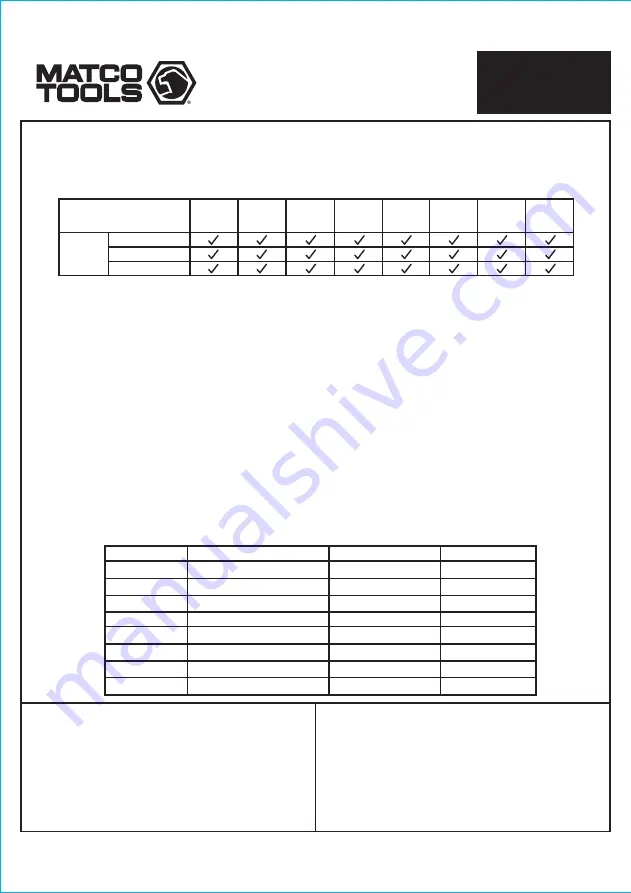

Common Sizes Chart:

*

Tool is capable but may require very high grip strength

8.5" x 5.5" x 2.4"

2.5 lbs.

6.35mm (1/4")

Rivet Nut Size

Nut

Material

SAE

10-24

SAE

1/4-20

SAE

5/16-18

SAE

3/8-16

M5

M6

M8

M10

Aluminum

Steel/Copper

Stainless Steel

Rivet Nut

M5

M6

M8

M10

10-24

1/4-20

5/16-18

3/18-16

Rivet Nut Diameter

6.9mm OD

8.9mm OD

10.9mm OD

12.9mm OD

6.9mm OD

8.9mm OD

10.9mm OD

12.9mm OD

Drill Hole Size

7mm (9/32")

9mm (3/8")

11mm (7/16")

13mm (17/32")

7mm (9/32")

9mm (3/8")

11mm (7/16")

13mm (17/36")

Grip Range

26 – 16ga

26 – 13ga

26 – 11ga

26 – 11ga

26 – 16ga

26 – 13ga

26 – 11ga

26 – 11ga

*

*

I. PRODUCT TECHNICAL DATA:

Rivet Type:

Stroke Limit:

Working Torque:

Recommended RPM:

Requirements of Driving Tools:

Requirements of electric

or pneumatic Driving Tool:

Rivet Nut

Maximum 0.7"

Refer to section III. Operation Guide

Low speed, driver setting (<240 RPM)

• Adjustable torque setting

• Chuck capacity of 6.35mm (1/4") shank

• Minimum 12V for aluminum, or M5 and 10-24 steel rivet nuts

• Minimum 14.4V for steel rivet nuts in M6, M8, 1/4" and 5/16" or stainless in M5

or 10-24

•

Minimum full-size 18V+ for M10 and 3/8" rivet nuts and all other sizes in stainless

steel

(

WEAR GLOVES)

• Clutch provides a felt and/or audible indication of reaching max setting

• Adjustable torque setting

• Chuck capacity of 6.35mm (1/4") shank

•

With maximum torque > 190 in. lbs. for aluminum and steel rivet nuts in smaller sizes

•

With maximum torque > 400 in. lbs. for stainless steel rivet nuts

1. Wear adequate protective gear including ANSI

approved goggles and

THICK WORK GLOVES

(RUBBER COATED)

2. Only use the nut riveting adapter with driving tool

that matches with requirements specified on

Product Technical Data.

3. Switch off the driving tool before installing or

uninstalling the nut riveting adapter.

4. The objects to be riveted

MUST BE SECURED

BEFORE

riveting in order to avoid possible injury.

Unsecured objects may rotate with the driving tool

if not secured.

5. The driving tool MUST be stopped if user releases

the adapters body during riveting.

6. During disassembly for mandrel changing or

Maintenance

, take care as there are pre-loaded

springs within the tool.

RIVET NUT

ADAPTER KIT

RN9

Página 2

1802030-14