Rev.

Descrizione

Redatto/Gestito

Approvato

Cod.Ident.

Pagine

Data Em.

0.6

Manuale Istruzioni

GN

UTEC

B041.M01.EN

38

/47

07/2014

Chapter 8

MAINTENANCE

8.01

PERIODICAL CHECKS

DANGER

All the operations of maintenance, checking and control must be carried out by

personnel professionally qualified and knowledgeable about machine and mechanisms.

All the operations must be carried out when the machine is switched off and with the

feeding cable physically separated from a knife switch of feeding.

It is permitted to use only the original spare parts.

The use of not original spare parts free the constructor from the responsibility.

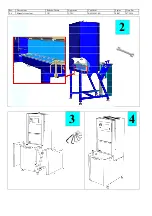

OPERATION

CHECK OF THE GENERAL EFFICIENCY

PROCEDURE

Carry out a visual inspection of the compactor and check that all parts

are in good working conditions and have not been damaged.

The components subject to wear: base disc, wheels, piston.

FREQUENCY

ALWAYS BEFORE EACH SINGLE USE

OPERATION

CHECK MOULD EFFICIENCY

PROCEDURE

Visual inspection. (See standards reference)

FREQUENCY

ALWAYS BEFORE EACH SINGLE USE

OPERATION

COMPACTOR CLEANNESS

PROCEDURE

Remove all the residuals especially from the internal plate of the cart by using a vacuum

cleaner or specific cleaning products. After the cleaning of plate, spread a layer of lubricating

grease on the surface using a brush.

FREQUENCY

ALWAYS BEFORE EACH SINGLE USE

OPERATION

CHECK OF THE SAFETY DEVICES FUNCTIONALITIES

PROCEDURE

Let the machine works for some minutes and simulates a test.

Check the safety devices functionalities: the switch on the front guard, the emergency button,

the general switch and the commands. If the machine stops the test, the safety device works

correctly; if not, the operator has to stop the test immediately and follow the instructions of the

chapter “GUIDE TO RECOGNISING DAMAGE AND ANOMALIES”.

FREQUENCY

ALWAYS BEFORE EACH SINGLE USE

8.02

PERIODIC CHECKS

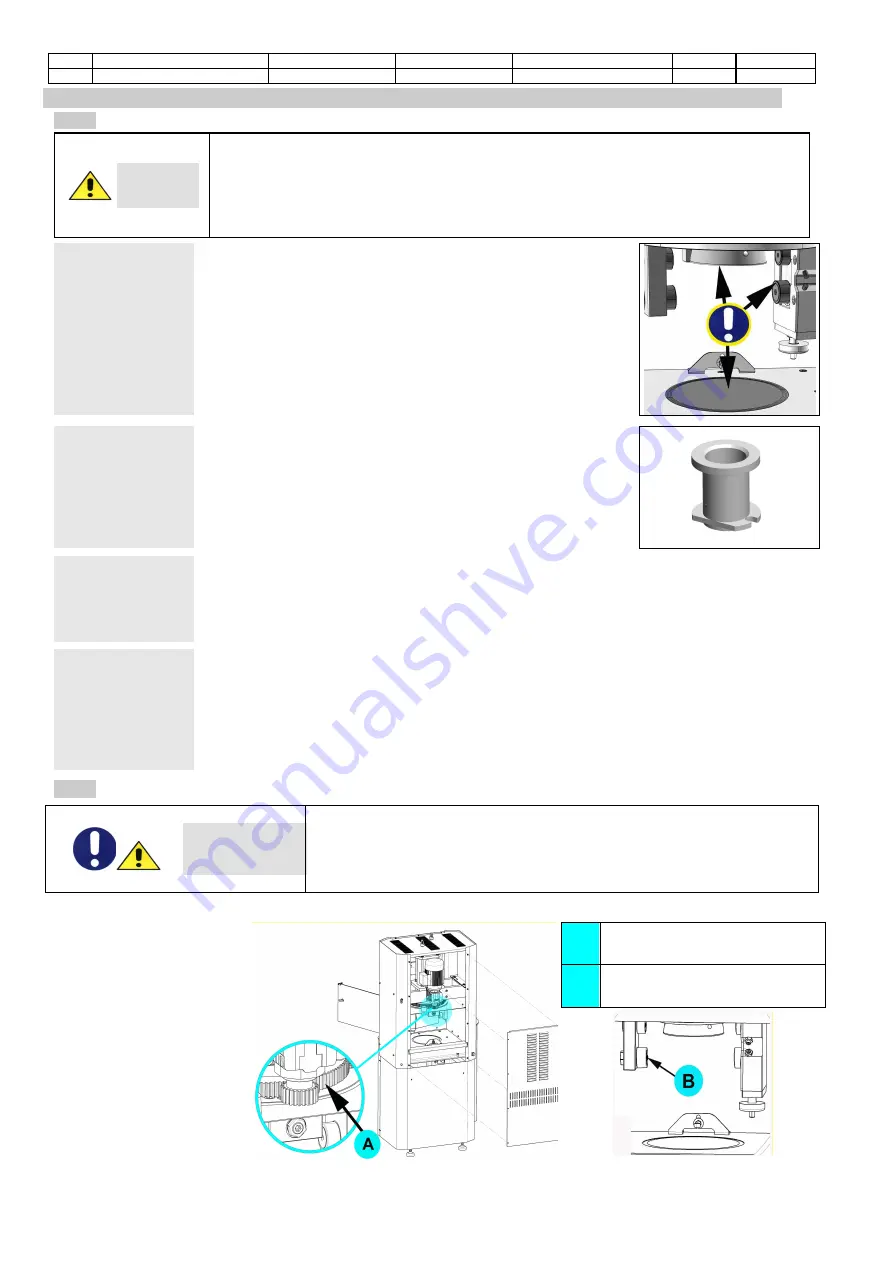

DANGER

WARNING

Do not perform maintenance – interventions on the machine which have

not been quoted and described in this instructions manual without first

contacting the manufacturer.Periodically clean all machine parts and oil the

unpainted parts in order to preserve the machine and its efficiency.Avoid

the use of solvents which damage paint and parts in synthetic material.

The following is proposed the program recommended lubrication intervals in hours of operation.

POINTS OF

LUBRICATION

A

GEAR MACHINE

Frequency: 1000 hours

B

Wheels (N° 5) frequency:

1000 hours