Rev.

Descrizione

Redatto/Gestito

Approvato

Cod.Ident.

Pagine

Data Em.

0.6

Manuale Istruzioni

GN

UTEC

B041.M01.EN

9

/47

07/2014

DANGER

Continuous use of the appliance and machines predictably present in the

installation environment could cause a heightened daily personal exposure to

noise.

Chapter 3

GENERAL SAFETY STANDARDS

3.01

GENERAL STANDARDS

To ensure the safety of machine operators:

· Any tampering with the appliance not pre-

emptively authorised by the manufacturer exempts

the manufacturer from any responsibility for

damage caused by or to it.

·The removal or tampering with safety devices

entails a violation of the safety standards.

· Machine use is only allowed in areas where

there is no risk of explosions or fires.

· Only the original fittings can be used. The use of

unoriginal fittings exonerates the manufacturer from

all responsibility.

• Check the appliance is in ideal working conditions

and that its parts are not worn or faulty before

Carry out all necessary maintenance

• Do not wear loose clothing, ties, chains or

anything else which could become caught in the

frame or other moving parts of the appliance.

• Be aware of the danger of electrical shocks from direct

or indirect contact due to unforeseen electrical faults.

• Do not subject the appliance to violent impact.

• Do not expose the appliance to fire, welding sparks or

extreme temperatures.

• Do not bring the appliance into contact with corrosive

substances.

• Do not wash the appliance with jets of water.

Check the workspace around the machine is clear from

potentially dangerous objects.

The machine operator must wear appropriate work

clothing such as protective glasses, gloves and mask in

order to avoid damage from, for example, harmful dust

projection. Wear a lower back support when lifting heavy

parts.

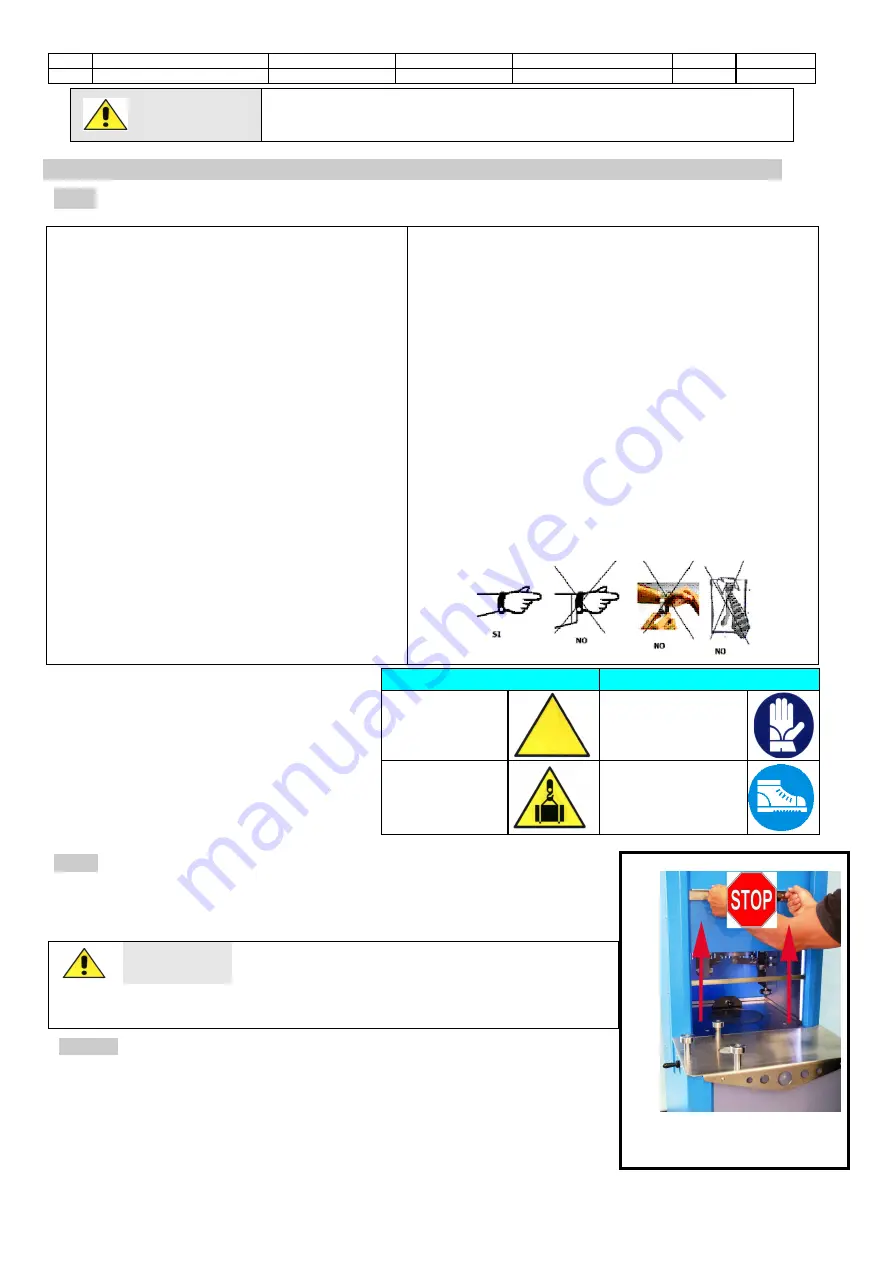

There should be no hanging objects such as bracelets

or otherwise, long hair should be protected with relevant

precautions, shoes must be appropriate for the type of

operation to be carried out.

DURING USE

When operating check there are no

conditions of danger. Immediately stop the

machine when it is functioning irregularly.

Contact

the

authorised

Sales

Service

department.

• For the operator’s safety do not touch any

part of the appliance when testing and use

the appropriate individual protection devices

in order to keep the operator safe.

RISK OR DANGER

PROTECTION DEVICES

FINGER

SQUEEZE

CUTS OR

ABRASIONS

REINFORCED

GLOVES

MATERIAL

FALL

ACCIDENT-

PREVENTION

SHOES

3.02

MACHINE SAFETY DEVICES AND PROTECTION

DEFINITION: Protections are all the safety measures that consist of the use of

specific technical means (repairs, safety devices) to protect people from dangers

which cannot be limited reasonably in design.

DANGER

Tampering with the protections or any appliance

modification could cause risks to users or other

exposed people.

The manufacturer does not assume any responsibility for direct or in direct damage

to people, things or animals following tampering with the protections.

3.03

PASSIVE SAFETY DEVICES

Passive safety devices are the devices or solutions which eliminate or reduce the

risks to the operator without any active intervention by the operator.

The machine has got a protection door ,which prevents the opening during the test

so that the operator cannot come in touch either with the internal mechanisms .The

door opening causes an immediate interruption of the power feeding; in this way the

motor and the road wheel stop moving. The rotation can start again only after the

Picture

. 6