ⓒ

2021 Matica Technologies Group. All rights reserved

46

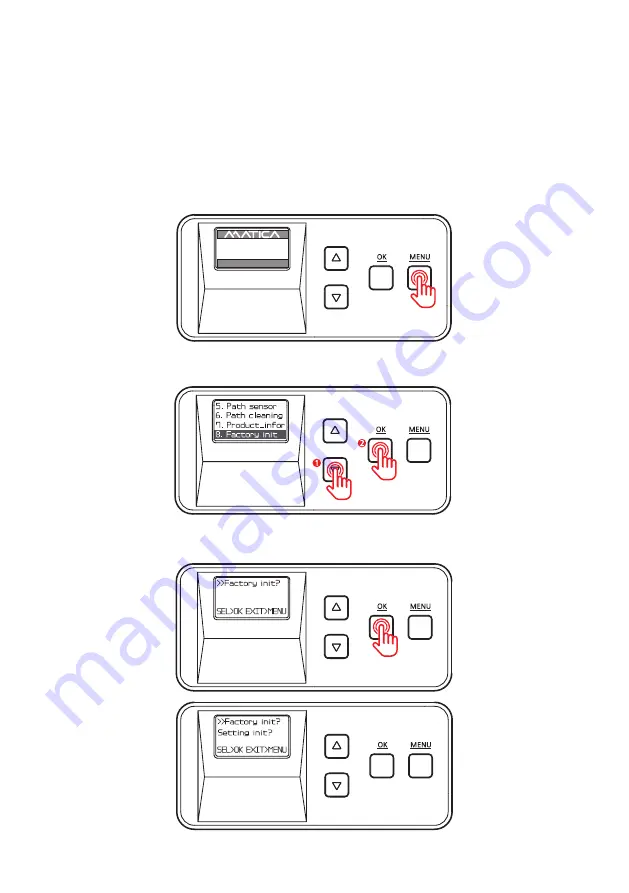

1. Press

‘MENU’

to enter the menu mode.

-Factory Reset (Factory init)

Function :

Reset the system to factory default settings.

Default Settings: Pass mode : Auto, Temper_set: 160 (320 ),

Start_POS set : 0mm, Power_saving: 5min

2. Press the Menu Navigation Button to select

‘8. Factory init’

and press

‘OK’

.

3.

Press

‘OK’

and

‘Setting init?’

appears on the screen.

UP 500 / LO 500

W30 / READY

2019.07.29(V0XX)