2000

B

D

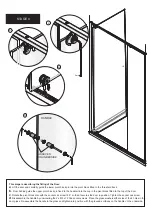

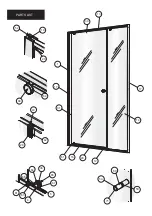

Before disposing of carton and/or commencing assembly, please check all the parts to ascertain that none are missing and they are all

undamaged

.

No claim for missing/damaged parts will be accepted once the packing carton has been disposed of and/or assembly has

commenced.

In case of query contact your Stockist with details of model number and details of serial number.

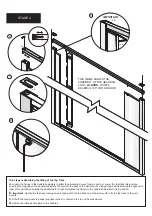

PREPARATION IMPORTANT

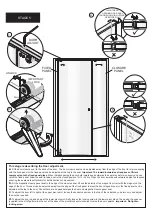

1. Please read complete installation instructions before fitting for Enclosure and Tray (if fitting).

2. We recommend the use of Safety glasses and Non slip gloves when handling the glass panels.

3. Ensure that the product can be

fixed

to a

solid masonry wall

or suitable

timber stud work grade C16/C24

in the area behind the

Wall frames.

4. Shower trays or tiled floors

must be absolutely level

where enclosures are fitted

5. If fitting a tray we recommend a

drainage test

is carried out before the tray is tiled in position.

6. The assembly should be installed onto a waterproof wall covering and installed after the Tray and wall coverings are in place. Where

Tiling lips are provided Trays should be let into the Wall with the Tiling lip flush with the wall to allow the Tiling to overlap the Tiling lip.

7. Seal between tray and tiles. Remove any excess sealant from the area/joint between the tray and the tiles where the Wall Mount is

to be fitted. This will ensure the Wall mount fits correctly to the wall and tray/or tiled floor.

CAUTION: TEMPERED GLASS CANNOT BE CUT, POLISHED METAL AND CHROME CAN BE SCRATCHED.

C

AREFULLY

REMOVE ASSEMBLY FROM CARTON, DO NOT PLACE GLASS ON HARD FLOOR OR EXPOSE EDGES TO IMPACT.

IMPORTANT

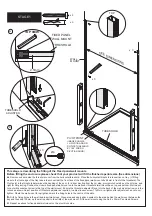

TOOLS REQUIRED

Masonry Drill bit 6mm, Tape Measure, Screw Drivers, Safety Glasses, Electric Drill, Level, Pencil,

Adjustable Spanners, Non Slip Gloves, 2mm/3mm/4mm Allen Keys

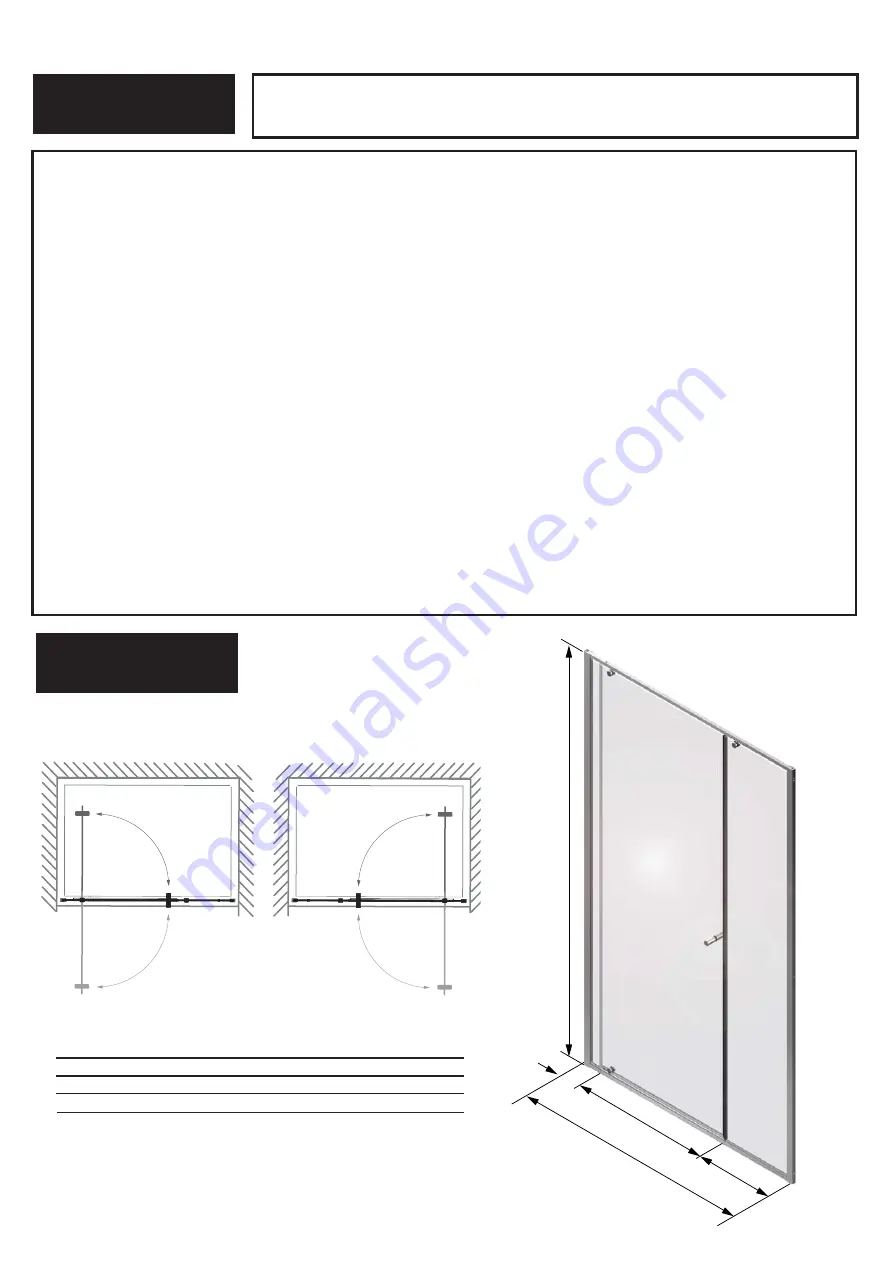

Dimensions are approximate

DIMENSIONS

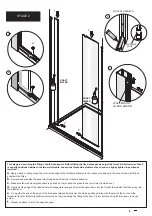

LH OPENING

(AS FACTORY ASSEMBLED)

RECESS INLINE PIVOT

1000/1100/1200

RH OPENING

C - DOOR OPENING

A - OVERALL

WIDTH

Model A B C D

MOPR1000 960-1000 80-100 482 329-349

MOPR1100 1060-1100 80-100 522 389-409

MOPR1200 1160-1200 80-100 622 389-409