a

b

c

d

d

100mm

e

100mm

d

100mm

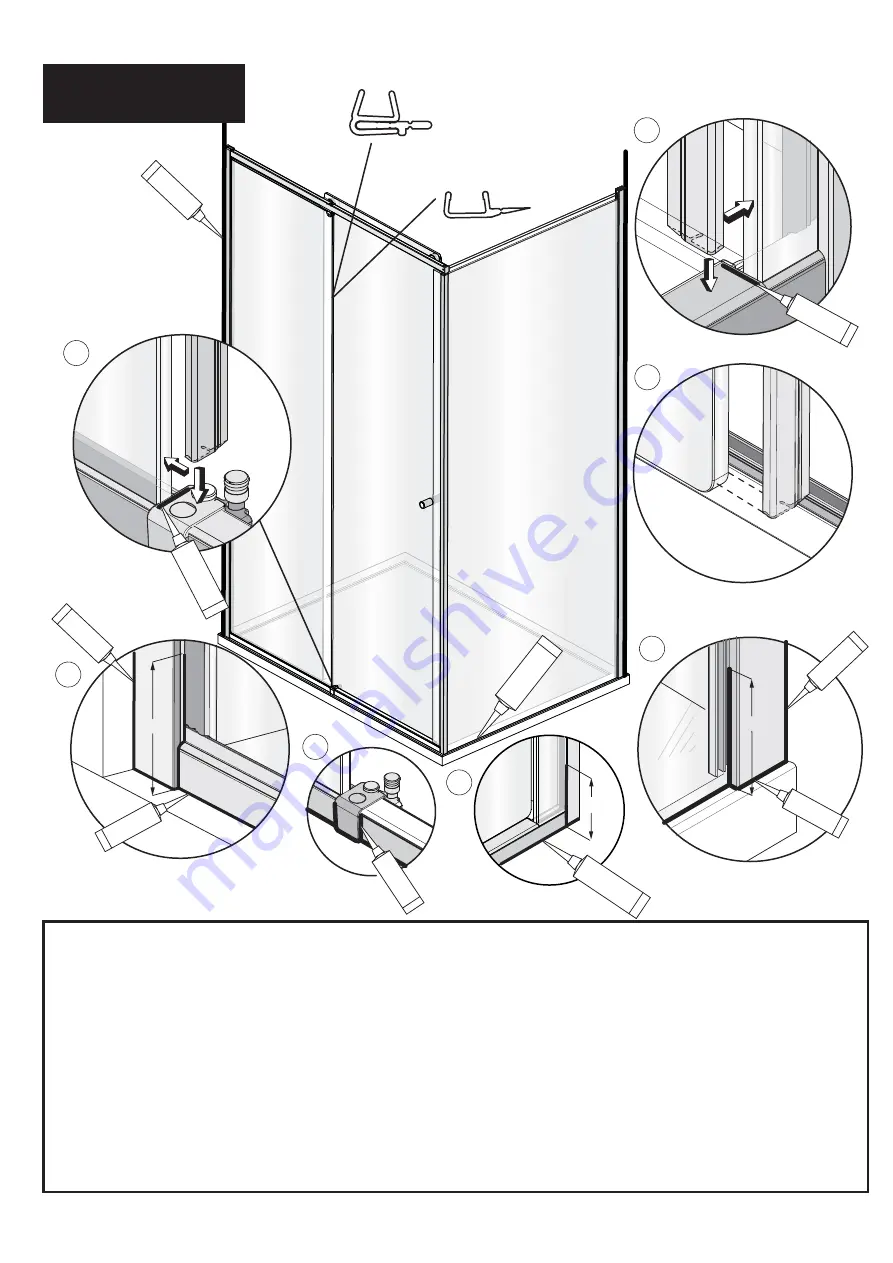

STAGE 10

SILICON

SILICON

INSIDE

VIEW

DOOR

GLASS

SILICON

SILICON

SILICON

SILICON

SILICON

SILICON

SILICON

SILICON

This stage is describing fitting of the Seals and Silicon

a.

Apply a bead of silicon along the top of the door guide. Fit the fixed panel vertical seal (shorter of the 3 seals) to the edge of the

fixed panel, ensuring it is pressed firmly against the face of the door guide. For 1000 model use the 2 part seal.

b.

Apply a bead of silicon along the top of the threshold cover where it meets the closure panel. Fit the closure panel vertical seal to

the edge of the closure panel, ensuring the seal sits firmly down onto the face of the threshold cover .

c.

Fit the door vertical seal to the back edge of the door glass, the bottom of the seal should be lined up with the top of the radius at the

corner of the glass.

d.

Apply a thin bead of silicon along the bottom edge of both the wall mounts and all the way up the outside of both the wall mount

extrusions between the wall mounts and the tiles. Apply a thin bead all the way along the threshold between the extrusion and the

finished floor surface/tray around the corner extrusion and along the bottom of the side panel where it meets the floor/tray. Continue

around the joint where the threshold joins the wall mounts and also 100mm up on the outside where the wall mounts and glass meet

and where the corner extrusion and glass meet. Apply a bead of silicon on the outside around the joints between the door guide and

threshold extrusion (e).

Masking tape can be used to achieve a tidy edge to the sealant. Remove the masking tape immediately and allow the silicon to cure for

24 hours before using the shower.

1100 / 1200 / 1400

1500 / 1600 / 1700

MODELS

1000

MODEL ONLY