13

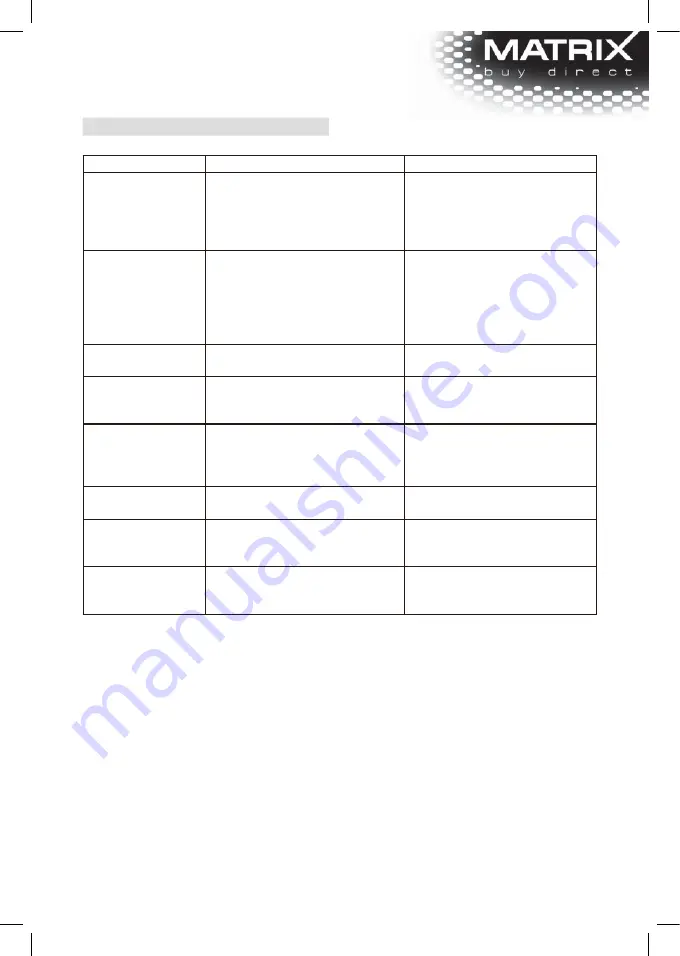

Troubleshooting

Problem

Possible Cause

Help

The motor does not

run.

Faulty motor, power supply cable or

plug.

Burned out fuses.

Have the machine checked by

skilled personnel. Do not try to

repair the machine yourselves as it

may be dangerous. Check the

fuses and replace them if necessary.

The motor starts

slowly and does not

reach running speed.

Low-power supply voltage.

Damaged windings. Burned out

capacitor.

Ask the Electricity Distributor

to check the voltage available.

Have the machine motor checked

by skilled personnel. Have the

capacitor replaced by skilled

personnel.

Excessive motor noise.

Damaged windings. Faulty motor.

Have the motor checked by skilled

personnel.

The motor does not

reach full power.

Overloaded circuit due to lighting,

utilities or other motors.

Do not use other utilities or motors

on the circuit to which the cutting-

off machine is connected.

Motor overheats

easily

Overload of the motor; inadequate

cooling of the motor.

Prevent overloading the motor

when cutting; remove dust from

the motor to ensure an optimum

cooling of the motor.

Decrease in cutting

power when

The saw blade is too small

(sharpened too often).

Re-adjust the end stop of the saw

unit.

The saw cut is rough

or wavy.

The saw blade is dull; the tooth

shape is not suited to the thickness

of the material.

Re-sharpen the saw blade or use an

appropriate saw blade.

The work piece rips or

splinters.

The cutting pressure is excessive or

the saw blade is not suited to the

application.

Use the correct saw blade.