13

CHAPTER 6: P

reventative

m

aintenance

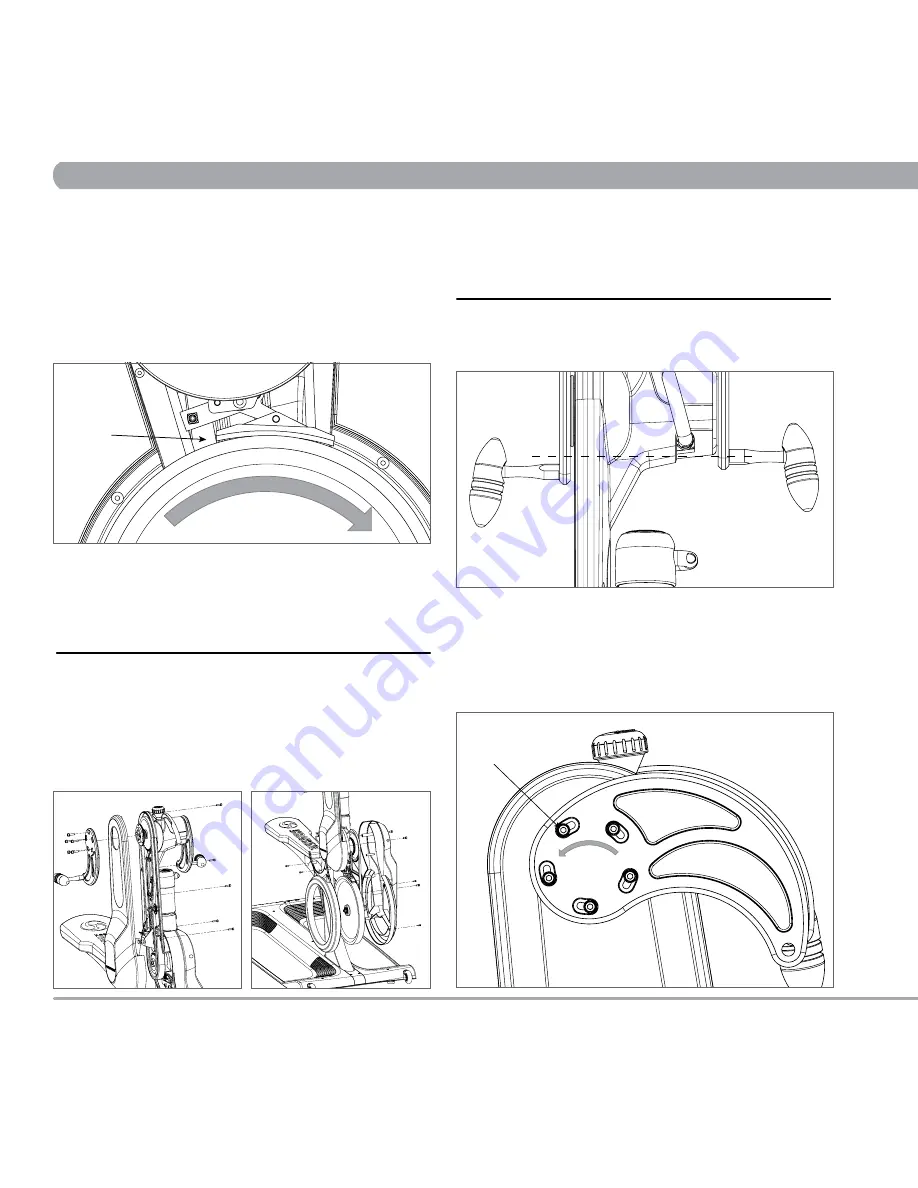

b. Check brake pad setting by first turning the resistance knob toward the

“-“ sign as far as it will go (minimum braking effect). The brake pad should

have approximately a credit card thickness between it and the flywheel and

the brake pad should feel slightly loose around its pivot. If adjustment is

required see

TROUBLESHOOTING GUIDE

(see page 13).

c. Check brake pad for signs of wear and the presence of lubrication. If the

brake pad requires lubrication, first adjust the resistance knob so the brake

pad is just slightly touching the flywheel. Then slowly rotate the flywheel

with one hand while applying a small amount of lubricant on the flywheel

just behind the brake pad (A) on the in-going side. Wipe off excess.

d. Replace brake pad if necessary

e. Replace lower inside plastic cover

2. Check and tighten (if necessary) the screws on crank arms, adjustment

knobs and levers, seat, water bottle holder, and plastic covers.

6.4 BI-YEARLY (6 MONTH) MAINTENANCE

1. For optimal performance of the drive system the following steps should

be taken:

a. Remove the RIGHT crank arm by removing 5 socket head cap screws

with a 4mm ALLEN KEY WRENCH then remove the upper outside plastic

cover by removing 5 socket head cap screws with a 3mm ALLEN KEY

WRENCH. Then remove both of the lower plastic covers by removing 9

socket head cap screws with a 3mm ALLEN KEY WRENCH and 5mm

ALLEN KEY WRENCH.

b. Thoroughly wipe down around all internal components and look for signs

of excessive wear or damage.

c. Lubricate both upper and lower drive chains. Clean excess.

d. Replace drive chains if necessary

e. Replace all plastic covers and RIGHT crank arm

6.5 TROUBLESHOOTING GUIDE

Follow the steps below if any problems are discovered in the weekly

function test.

CRANK ARMS NOT SYNCHRONIZED

Turn the resistance knob toward the “+” sign until the crank arms do not

fall by themselves back to the lowest rest position. Raise the crank arms

so the crank handles are nearly level. Loosen (do not remove) the 5 socket

head cap screws (B) on the RIGHT crank arm with a 4mm ALLEN KEY

WRENCH. Adjust the position of screws within the slots until both crank

handles are level and then tighten. Make sure all screws are tight, or the

crank handle may slip out of synchronization again.

Rotation Direction

A

B