16

CHAPTER 6: P

reventative

m

aintenance

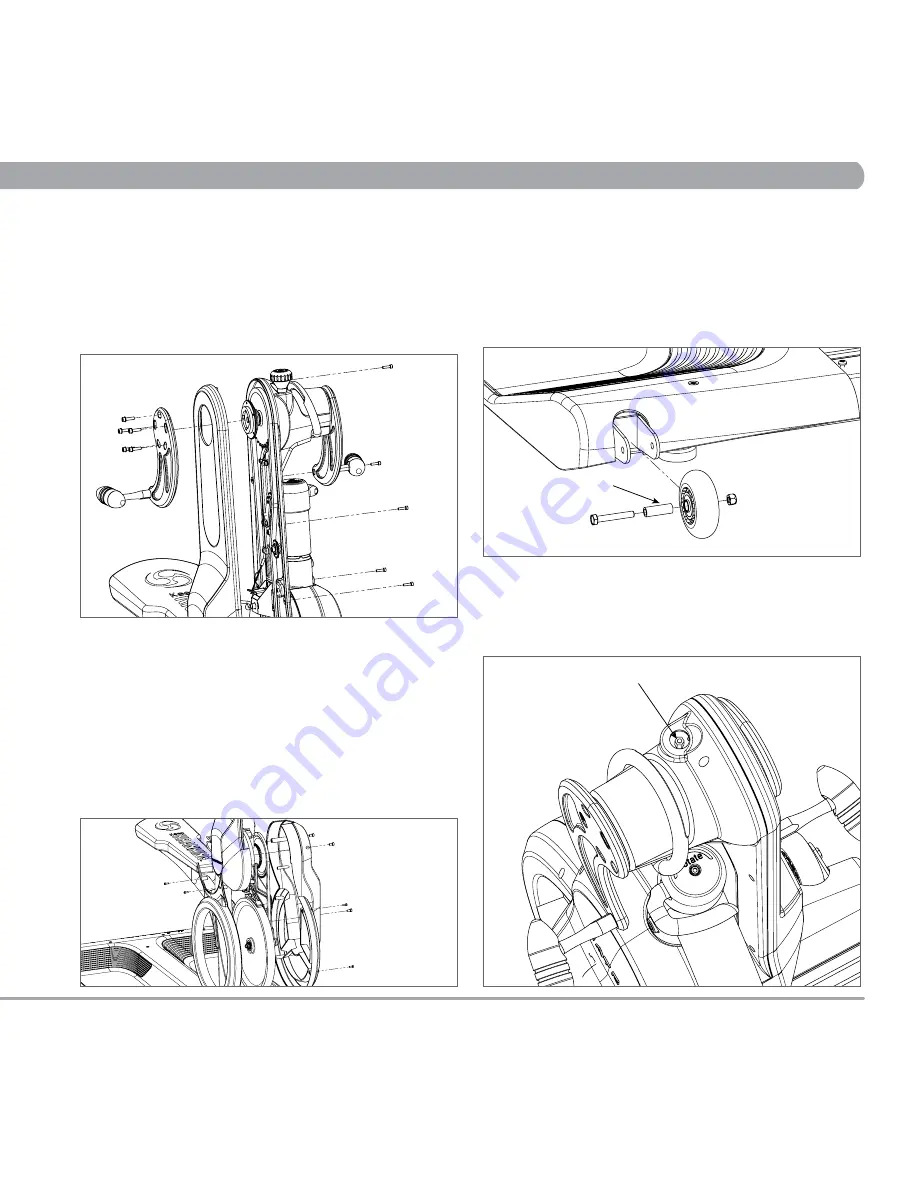

UPPER CHAIN DRIVE MAKING A PRONOUNCED CLICKING NOISE

Over time, it is normal for the drive chains to stretch with use. The

Krankcycle is equipped with automatic chain tensioning devices, but the

chain may need to be replaced if it has stretched too far. Follow the next

steps to check for excessive chain wear or stretch. If the chain needs to be

replaced,contact MATRIX customer service.

Remove the RIGHT crank arm by removing 5 socket head cap screws with a

4mm ALLEN KEY WRENCH then remove the upper outside plastic cover by

removing 5 socket head cap screws with a 3mm ALLEN KEY WRENCH.

If the chain is rubbing on the inside covers the chain should be replaced by

a service technician

Replace upper outside plastic cover and

RIGHT

crank arm

LOWER CHAIN DRIVE MAKING A PRONOUNCED CLICKING NOISE

Over time, it is normal for the drive chains to stretch. The Krankcycle

is equipped with automatic chain tensioning devices, but the chain may

need to be replaced if it has stretched too far. Follow the next steps to

check for excessive chain wear or stretch.

Remove both of the lower plastic covers by removing 9 socket head cap

screws with a 3mm ALLEN KEY WRENCH and 5mm ALLEN KEY WRENCH.

If the chain is rubbing on the inside covers or exhibits too much play

around the sprockets the chain should be replaced by a service technician.

Replace both lower plastic covers.

CYCLE DIFFICULT TO PUSH WHEN MOVING

The front rolling wheels may need lubrication. Remove both wheels by

unscrewing the nut and bolt. Lubricate the outside of steel axle tube (A).

Replace both wheels using a 10mm WRENCH.

RESISTANCE KNOB DOES NOT ROTATE SMOOTHLY

The resistance cable mechanism may need lubrication. Remove the

resistance knob by removing the 1 socket head cap screw with a 4mm

ALLEN KEY WRENCH. Lubricate the cable mechanism (B) through the

opening in the plastic cover. Replace the resistance knob.

A

B