41

7.2 Rear roller removal

Figure A

Figure B

1. Turn off power and disconnect the cord

from the machine

2. Remove one of the end caps using a

screwdriver (Figure A)

3. Remove both roller adjustment screws using an

8mm hex-tip tools ( Figure B and C)

4. Remove roller from running belt

(Figure D and E)

Figure C

Summary of Contents for MX-T3x

Page 1: ...1 MX T3x TM94E AC SYSTEM SERVICE MANUAL...

Page 4: ...4 SERIAL NUMBER LOCATION SECTION 1...

Page 5: ...5 Matrix T3x TM94E Serial Number Location...

Page 6: ...6 MOVING THE UNIT SECTION 2...

Page 8: ...8 IMPORTANT SAFETY I N S T R U C T I O N S SECTION 3...

Page 12: ...12 PREVENTATIVE MAINTENANCE SECTION 4...

Page 19: ...19 SECTION 5 MANAGER MODE...

Page 23: ...23 SECTION 6 TROUBLE SHOOTINGS...

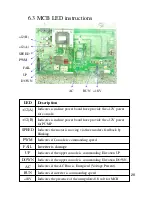

Page 24: ...24 6 1 Electrical block diagram...

Page 25: ...25 6 2 Wire pin definition P01 Console Wire...

Page 26: ...26 P04 Inverter Wire N24 Pulse Board Wire...

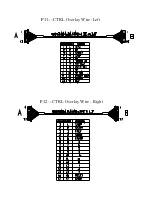

Page 27: ...27 P11 CTRL Overlay Wire Left P12 CTRL Overlay Wire Right...

Page 35: ...35...

Page 39: ...39 SECTION 7 PARTS REPLACEMENT...

Page 42: ...42 Figure D Figure E...

Page 53: ...53 Figure D Figure E Figure F Figure G...

Page 57: ...57 Install the MSP430 Tools Computer...

Page 58: ...58 Press the Load Image Installation software to MSP430 Tools...

Page 59: ...59 Installing the MSP430 cable to console MSP430...

Page 61: ...61 SECTION 8 UPGRADES...