Re-allow the temperature to increase and the steam

ready light will re illuminate (9)

The steam output can be adjusted by the variable

steam control (2)

Choose and fit the required accessory to the hose

handle.

When changing accessories during use please

note these will be hot!!

During Use

Cold water tank empty

Refill the cold water tank (1) when the refill cold

water LED (10) is illuminated.

A buzzer will sound and the steam will no longer

come out of the nozzle when the steam switch on

the handle is pressed.

The pumps will not work when the cold-water tank

is empty.

Once the cold water refill LED is illuminated the

boiler heater will remain on for 30 minutes. If the

cold-water tank is not refilled within 30 minutes

and the machine is left powered on the boiler

heater will switch off.

Storing the hose after use

On completion remove the hose from the front of

the machine and store in basket/bag provided,

once cooled.

Safety Precautions

This machine is to be used by trained

operatives only

DO

•

Check the cable and plug are safe and intact

before plugging the machine in.

•

Place cleaning in progress signs where

necessary

•

Point the steam nozzle away from your body

during use

•

Empty and clean machine after each use

DON’T

•

Use the machine near people, children or

animals

•

Point steam at electrical apparatus

•

Use the machine to clean the machine down

•

Do not use on Velvet, satin or leather

•

Leave the machine unattended

Maintenance

The maintenance of the machine is a prerequisite for

impeccable operation and a long service life.

Use original MATRIX parts only; otherwise, any

warranty and liability claims will expire.

In order to rule out unintended machine functions,

before starting maintenance works the following

must always be carried out

- the machine must be switched off,

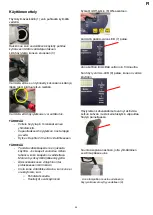

Daily Maintenance

To be carried out every day or every 8 hours of

operation.

1. Grease “O” rings on the steam pin in the

steam hose.

2. Wipe down the body of the machine with a

clean damp cloth

3. Always wash the accessories in hot soapy

water.

(Do not immerse the machine or

hose in water)

4. Wrap the power cable up before storing

away.

Weekly Maintenance

To be carried out every week or every 50 hours of

operation.

As for daily maintenance plus the following:

1. Inspect the power cable for any signs of

damage. If damaged do not repair, contact

the supplier of this product. Do not use

until repaired.

2. Inspect the hose assembly for any signs of

damage. If damaged do not repair, contact

the supplier of this product. Do not use

until repaired.

3. Inspect castors to ensure all securing bolts

are fully tightened.

Warning

Caution

Notice

42

Summary of Contents for SO8

Page 129: ...129 ...