55

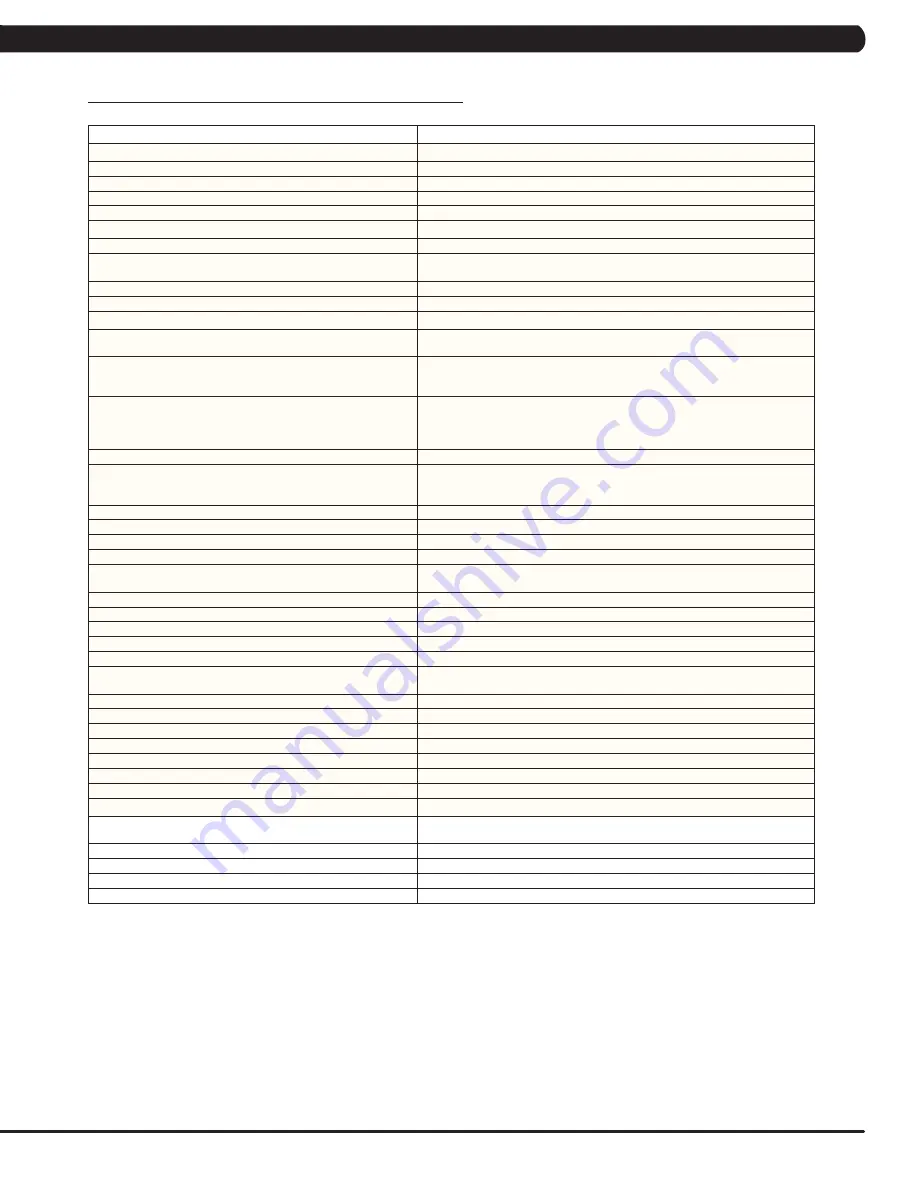

10.1 U3x-05 BIKE SPECIFICATIONS

CHAPTER 10: BIKE SPECIFICATIONS AND ASSEMBLY GUIDE

U3x UPRIGHT

FEATURES

CONTACT & TELEMETRIC HR SENSORS YES

HANDLEBAR DESIGN

FULL RACING STYLE WITH ELBOW SUPPORT

INTEGRATED ARM RESTS

N/A

THUMB SWITCH CONTROLS

YES

RESISTANCE SYSTEM

TECHNOLOGY

JID BRUSHLESS GENERATOR

POWER REQUIREMENTS

SELF POWERED - POWERED 100-125 V, 60 HZ

OR 216-250 V, 50 HZ

MINIMUM WATTS

13 SELF POWERED

MINIMUM RPM

10 POWERED / 25 SELF-POWERED

CONSOLE

DISPLAY TYPE

14-SEG ALPHANUMERIC, 8X16 LED GRAPHIC

DISPLAY

DISPLAY FEEDBACK

TIME ELAPSED, TIME REMAINING, PROGRAM

TIME, SPEED, METS, LEVEL, CALORIES, RPM,

WATTS, HEART RATE, STATIC PROFILE DISPLAY

USER DEFINED MULTI-LANGUAGE

DISPLAY

NO - ACCESSIBLE THROUGH MANAGER

MENU: ENGLISH, GERMAN, FRENCH, ITALIAN,

SPANISH, DUTCH, PORTUGUESE, SWEDISH,

FINNISH

RESISTANCE LEVELS

25

WORKOUTS

MANUAL, ROLLING HILLS, INTERVAL TRAINING,

RANDOM, FAT BURN, FITNESS TEST, HEART

RATE, CONSTANT WATTS

CSAFE READY - FITLINXX™ CERTIFIED

NO

NETPULSE COMPATIBLE

NO

ON-THE-FLY PROGRAM CHANGE

YES

FIT TOUCH TECHNOLOGY™

NO

INTEGRATED VISTA CLEAR™ DIGITAL

READY TELEVISION

NO

VIRTUAL ACTIVE™ COMPATIBLE

NO

FITCONNEXION™ READY

YES

WIFI

NO

ETHERNET PORT

YES

WEB CONNECTIVITY

NO

FACILITY COMMUNICATOR PORTAL/

CALENDAR

NO

ASSET MANAGEMENT COMPATIBLE

NO

IPOD® COMPATIBLE

NO

IPHONE® COMPATIBLE

NO

USB PORT

YES

MULTIMEDIA PLAYBACK

NO

NIKE + IPOD® COMPATIBLE

NO

PERSONAL FAN

NO

TECH SPECS

OVERALL DIMENSIONS

L X W X H

47.8" X 28.8" X59"

121.5CM X 73.2CM X 149.8CM

CRANK DESIGN

SINGLE PIECE

MAXIMUM USER WEIGHT

400 LBS/182 KG

WEIGHT

138 LBS./63 KG

SHIPPING WEIGHT

160 LBS/72.6 KG

NORTH AMERICAN SPECIFICATIONS SHOWN. SPECIFICATIONS SUBJECT TO CHANGE.

FOR LATEST SPECIFICATIONS PLEASE VISIT WWW.MATRIXFITNESS.COM

Summary of Contents for U3X-05

Page 1: ...U 3 X 0 5 B I K E S E R V I C E M A N U A L...

Page 4: ...1 1 1 SERIAL NUMBER LOCATION CHAPTER 1 SERIAL NUMBER LOCATION FRAME SERIAL NUMBER LOCATION...

Page 15: ...12 8 1 ELECTRICAL DIAGRAMS CHAPTER 8 TROUBLESHOOTING...

Page 16: ...13 8 1 ELECTRICAL DIAGRAM CHAPTER 8 TROUBLESHOOTING...

Page 19: ...16 8 1 ELECTRICAL DIAGRAMS CONTINUED CHAPTER 8 TROUBLESHOOTING PULSE EXTENDED WIRE...

Page 20: ...17 8 2 LCB LED INDICATORS CHAPTER 8 TROUBLESHOOTING...

Page 73: ...70 NOTES...