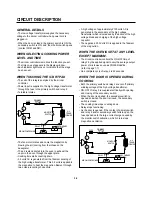

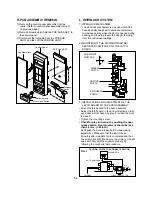

MEASUREMENT WITH OUTER CASE

REMOVED

• When you replace the magnetron, measure for

microwave energy leakage before the outer case is

installed and after all necessary components are

replaced or adjusted.

Special care should be taken in measuring the

following parts. (Circled area of below Fig.)

- Around the magnetron

- The waveguide

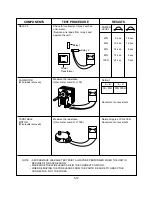

MEASUREMENT WITH A FULLY

ASSEMBLED OVEN

• After all components, including the outer case, are fully

assembled, measure for microwave energy leakage

around the door viewing window, the exhaust opening,

and air inlet openings.

• Microwave energy leakage must not exceed the values

prescribed below.

NOTE: Leakage with the outer case removedless than

5 mW/cm.sq. Leakage for a fully assembled

oven (Before the latch switch (primary) is

interrupted) with the door in a slightly opened

position-less than 2 mW/cm.sq.

NOTES WHEN MEASURING

• Do not exceed meter full scale deflection.

• The test probe must be removed no faster than

1 inch/sec (2.5 cm/sec) along the shaded area,

otherwise a false reading may result.

• The test probe must be held with the grip portion of the

handle.

A false reading may result if the operator's hand is

between the handle and the probe.

• When testing near a corner of the door, keep the probe

perpendicular to the surface making sure the probe

horizontally along the oven surface, this may possibly

cause probe damage.

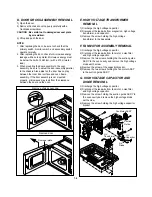

RECORD KEEPING AND NOTIFICATION

AFTER MEASUREMENT

• After adjustment and repair of any microwave energy

interruption or microwave energy blocking device,

record the measured values for future reference. Also

enter the information on the service invoice.

• The microwave energy leakage should not be more

than 4 mW/cm.sq. after determining that all parts are in

good condition, functioning properly and genuine

replacement parts which are listed in this manual have

been used.

• At least once a year, have the electromagnetic energy

leakage monitor checked for calibration by its

manufacturer.

5-2

WARNING : AVOID CONTACTING ANY

HIGH VOLTAGE PARTS

(Magnetron, H.V. Transformer,

H.V. Capacitor, H.V. Cable Ass’y,

H.V. Circuit Protector)

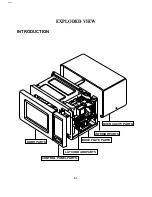

Summary of Contents for M130TCS

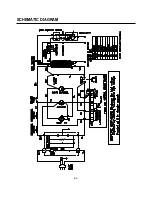

Page 9: ...SCHEMATIC DIAGRAM 4 3 OVEN THERMAL CUT OUT MGT THERMAL CUT OUT ...

Page 28: ...6 2 13536A 15006A 13552A 13213A 13352A 13720D 14970A 14026A 13581A DOOR PARTS EV ...

Page 29: ...6 3 24781M 268711 WTP015 250201 23506A 24510L 23572A 24970A 23550D CONTROL PANEL PARTS EV ...

Page 30: ...6 4 34036W 34960A 36549S 33112U WTT021 WTP013 33052A 33390G 35889A OVEN CAVITY PARTS EV ...

Page 31: ...6 5 466001 43500A 466001 466003 WSZ085 43501A LATCH BOARD PARTS EV ...

Page 33: ...6 7 63303A 63302A WTT021 WSZ002 65006B 56170D 948501 BASE PLATE PARTS EV ...

Page 34: ...8 1 SCHEMATIC DIAGRAM OF P C B ...

Page 35: ...8 2 PRINTED CIRCUIT BOARD ...

Page 36: ......