H. AIR DUCT ASSEMBLY REMOVAL

1) Disconnect the leadwire from the lamp.

2) Remove the mounting screw to the latch board.

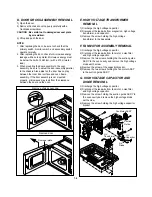

I. MAGNETRON REMOVAL

1) Disconnect the leadwire from the high voltage

transformer and high voltage capacitor.

2) Carefully remove the mounting screws holding the

magnetron and the waveguide.

3) Remove the magnetron ASS’Y until the tube is

clear from the waveguide.

NOTE:

1. When removing the magnetron, make sure its

dome does not hit any adjacent parts, or it may be

damaged.

2. When replacing the magnetron, be sure to install

the magnetron gasket in the correct position and

be sure that the gasket is in good condition.

3. After replacing the magnetron, check for microwave

leakage with a survey meter around the

magnetron. Microwave energy must be below the

limit of 5 mW/cm

2

. (With a 275 ml. water load).

Make sure that gasket is rigidly attached to the

magnetron. To prevent microwave leakage,

tighten the mounting screws properly, making sure

there is no gap between the waveguide and the

magnetron.

L. REMOVING THE TURNTABLE MOTOR

1) Remove the turntable.

2) Remove the turntable shaft VERY CAREFULLY.

3) Lay the unit down on its back.

4) Remove the turntable motor cover.

The turntable base cover is easily removed by

pinching the six parts with a wire cutting.

5) Disconnect the leadwire from the turntable motor

terminals.

6) Remove the screw securing the turntable motor to

the oven cavity ASS’Y

7) After repairing the motor, rotate the removed

turntable motor cover.

8) Fit the turntable motor cover’s projecting part to the

base plate slit.

NOTE:

1. Remove the wire lead from the turntable motor

VERY CAREFULLY.

2. Be sure to grasp the connector, not the wires, when

removing.

5-5

Waveguide

Magnetron

Magnetron

Gasket

Magnetron

Dome

Waveguide

Bracket

Wire Leads

Turntable Motor

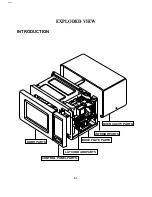

Summary of Contents for M130TCS

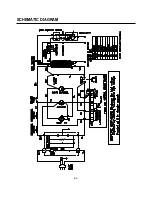

Page 9: ...SCHEMATIC DIAGRAM 4 3 OVEN THERMAL CUT OUT MGT THERMAL CUT OUT ...

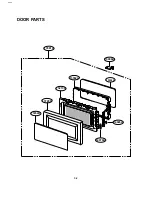

Page 28: ...6 2 13536A 15006A 13552A 13213A 13352A 13720D 14970A 14026A 13581A DOOR PARTS EV ...

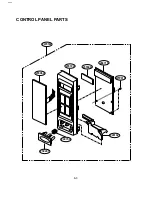

Page 29: ...6 3 24781M 268711 WTP015 250201 23506A 24510L 23572A 24970A 23550D CONTROL PANEL PARTS EV ...

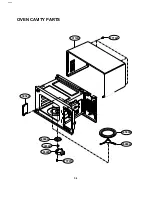

Page 30: ...6 4 34036W 34960A 36549S 33112U WTT021 WTP013 33052A 33390G 35889A OVEN CAVITY PARTS EV ...

Page 31: ...6 5 466001 43500A 466001 466003 WSZ085 43501A LATCH BOARD PARTS EV ...

Page 33: ...6 7 63303A 63302A WTT021 WSZ002 65006B 56170D 948501 BASE PLATE PARTS EV ...

Page 34: ...8 1 SCHEMATIC DIAGRAM OF P C B ...

Page 35: ...8 2 PRINTED CIRCUIT BOARD ...

Page 36: ......