For direct soldering

Safety and Usage of High Voltage Power Supply 2

Handling high voltage output cables

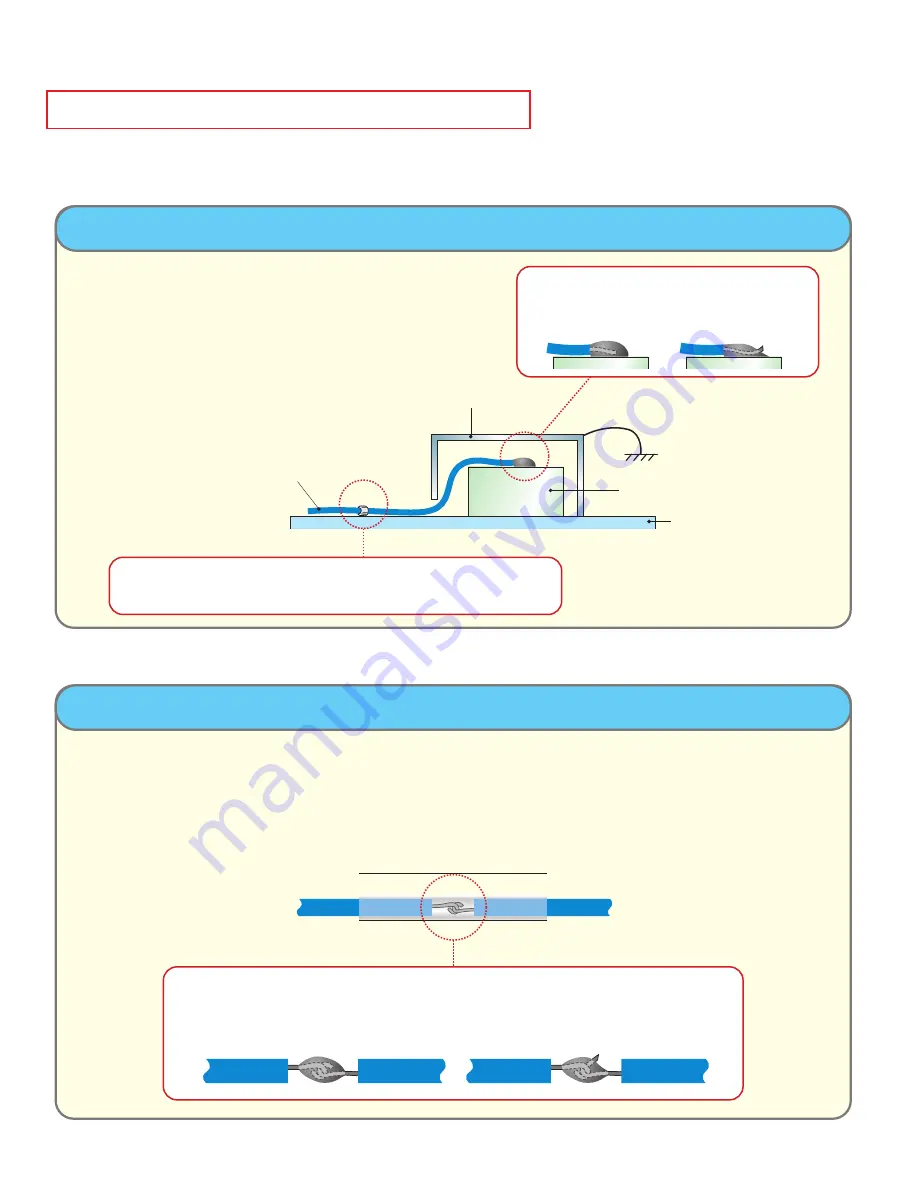

There are a variety of ways to make connections when applying high voltage. Here we describe an example method for

handling high voltage cables, and precautions that should be observed.

In order to avoid discharging electricity in a manner that

will cause bodily harm, either cover the object with an

insulator that has sufficient dielectric strength, or cover

it with an object that has ground potential so that electricity

is not discharged to a different location.

An insulated conductor or a ground potential conductor

Secure the cable in a mechanically method so that any force exerted on the cable

may not concentrate on the soldered area.

In the case of a conductor,

establish a ground for it.

Smooth the soldered area to finish it so that no “pointed” edges can be seen.

Something that hight voltage

will be applied to.

An insulator

Output cable

Finish soldering so that “pointed” edges is found.

When connecting high voltage cables together

When connecting high-voltage cables together to create a long high-voltage line, it is difficult to keep them connected simply by

linking them together as described above. Therefore, cover the connections with heat-shrink tubing that has dielectric strength.

Note that there is a risk of dielectric breakdown in the tube if its withstand voltage is not sufficient.

If the insulation withstand voltage of a single tube is not sufficient, use double or triple tubes to ensure sufficient

withstand voltage. In addition, if there are rough surfaces on the solder, dielectric breakdown might occur even if the tube has

sufficient insulation withstand voltage. Please be sure to make rounded solder joints.

Good

Not Good

Good

Not Good

03