measurements.

6. The potential at any point should not exceed 0.75 V RMS. A leakage

current tester (Simpson Model 229 or equivalent) may be used to make

the hot checks, leakage current must not exceed 1/2 mA. In case a

measurement is outside of thelimits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and rechecked

before it is returned to the customer.

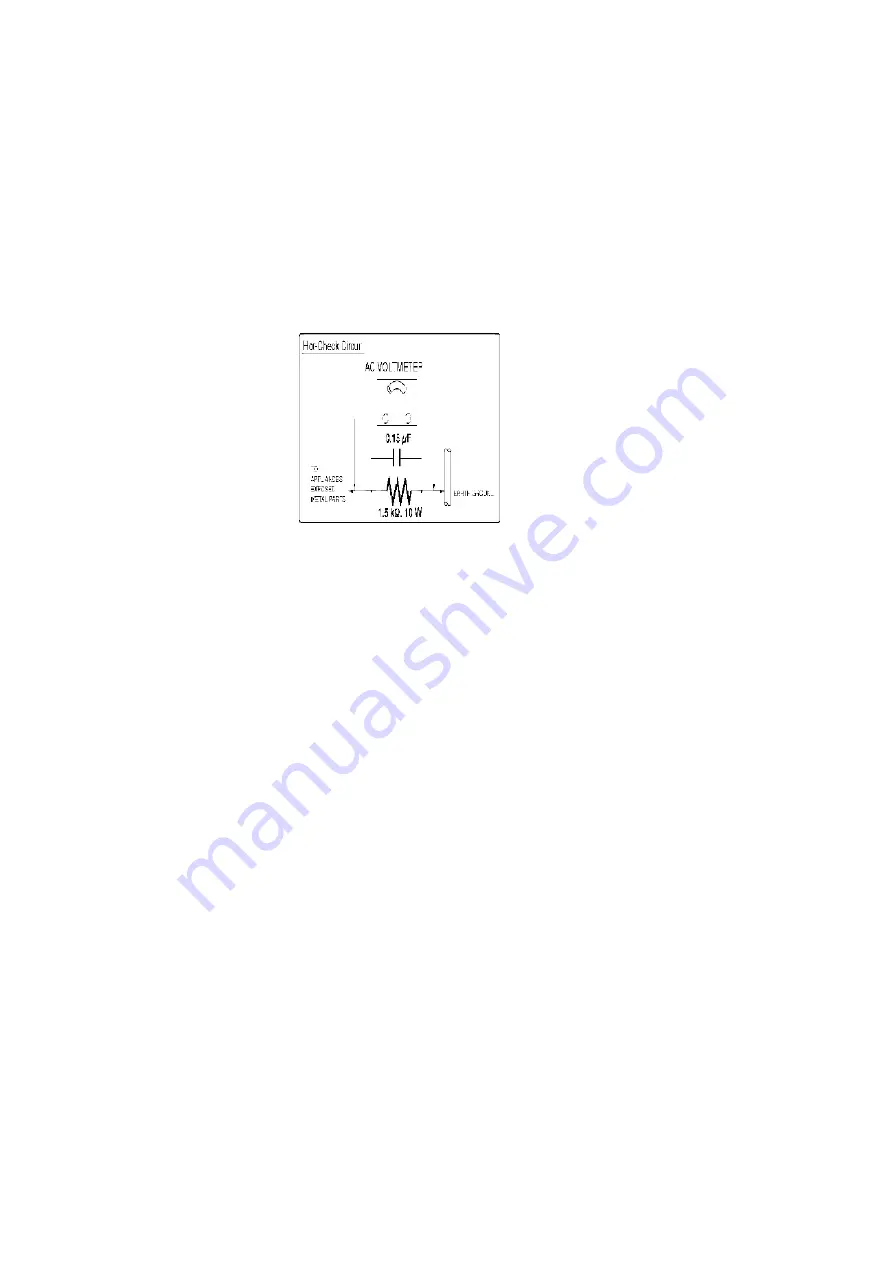

Figure. 1

2. Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Device

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such

components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistorsand semiconductor "chip" components.

The following techniques should be used to help reduce the incidence of component damage caused

by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any ESD on your body by

touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging ESD wrist strap,which should be

removed for potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES devices, place

the assembly on a conductive surface such as aluminum foil, to

prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an antistatic solder removal device. Some solder removal

devices not classified as "antistatic (ESD protected)" can generate

electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical

3

Summary of Contents for VDR-M53PP

Page 7: ...6 2 Specifications 7 ...

Page 8: ...8 ...

Page 9: ...9 ...

Page 11: ...11 ...

Page 13: ...8 2 Problem Guide 13 ...

Page 14: ...14 ...

Page 15: ...15 ...

Page 16: ...16 ...

Page 17: ...17 ...

Page 18: ...18 ...

Page 19: ...8 3 Messages and Troubleshooting 19 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 22: ...22 ...

Page 23: ...23 ...

Page 24: ...24 ...

Page 25: ...25 ...

Page 26: ...26 ...

Page 27: ...27 ...

Page 28: ...28 ...

Page 30: ...8 4 2 Details of error code display 8 4 3 Major error codes and troubleshooting 30 ...

Page 31: ...31 ...

Page 32: ...8 4 4 Cleaning disc and optical pickup 32 ...

Page 33: ...8 5 Checking Versions of Firmware and Updating 33 ...

Page 34: ...8 5 1 Checking firmware versions 34 ...

Page 35: ...8 5 2 Updating firmware 35 ...

Page 36: ...8 6 Trouble Diagnosis 36 ...

Page 37: ...8 6 1 Trouble disgnosis flowchart 37 ...

Page 38: ...38 ...

Page 39: ...39 ...

Page 40: ...8 6 2 Reassembly to enable service position 40 ...

Page 41: ...41 ...

Page 42: ...42 ...

Page 43: ...43 ...

Page 44: ...44 ...

Page 47: ...47 ...

Page 48: ...48 ...

Page 50: ...8 9 1 Forced initialization of DVD RAM 8 9 2 EEPROM data backup and write 50 ...

Page 51: ...51 ...

Page 52: ...52 ...

Page 53: ...53 ...

Page 54: ...9 Disassembly and Reassembly 9 1 Items to be Checked 54 ...

Page 55: ...9 2 Order of Disassembly 55 ...

Page 56: ...9 3 Disassembly 56 ...

Page 57: ...57 ...

Page 58: ...58 ...

Page 59: ...59 ...

Page 60: ...60 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 ...

Page 65: ...65 ...

Page 66: ...66 ...

Page 67: ...67 ...

Page 68: ...68 ...

Page 69: ...69 ...

Page 70: ...70 ...

Page 71: ...71 ...

Page 72: ...72 ...

Page 73: ...73 ...

Page 75: ...10 1 2 Power Supply and Materials for Creating Reference Data 75 ...

Page 76: ...10 1 3 Connecting when Creating Reference Data 76 ...

Page 77: ...10 1 4 Settings when Creating Reference Data 10 1 5 Copying or Deleting Adjustment Program 77 ...

Page 78: ...10 1 6 Starting and Terminating Reference Data Creation Program 78 ...

Page 79: ...79 ...

Page 80: ...10 1 7 Creating Reference Data 80 ...

Page 81: ...81 ...

Page 82: ...10 2 Setups for Adjustment 10 2 1 Checking Reference Data 82 ...

Page 83: ...10 2 2 List of Jigs and Tools for Adjustment 83 ...

Page 85: ...10 2 5 Setting for Adjustment 85 ...

Page 86: ...86 ...

Page 87: ...10 2 6 Starting and Terminating Adjustment Program 87 ...

Page 88: ...88 ...

Page 89: ...10 3 List of Adjustment Items 10 3 1 Adjustment Program Hierarchy Diagram 89 ...

Page 90: ...10 3 2 List of Adjustment Needed After Replacing Major Components 90 ...

Page 91: ...10 3 3 Purpose of Adjustment and Incompleted Phenomenon 91 ...

Page 92: ...10 4 Adjustment Procedure 10 4 1 Initial Data Write 92 ...

Page 93: ...10 4 2 Video Level 93 ...

Page 94: ...10 4 3 Burst Level 94 ...

Page 95: ...10 4 4 Autofocus 95 ...

Page 96: ...10 4 5 Auto Iris Control 96 ...

Page 97: ...10 4 6 Sampling Pulse 10 4 7 Linearity VDR M95 only 10 4 8 Matrix 97 ...

Page 98: ...10 4 9 Chroma Gain 98 ...

Page 99: ...99 ...

Page 100: ...10 4 10 Spot Noise 100 ...

Page 101: ...10 4 11 LCD 101 ...

Page 102: ...102 ...

Page 103: ...103 ...

Page 104: ...104 ...

Page 105: ...105 ...

Page 106: ...106 ...

Page 107: ...107 ...

Page 110: ...14 2 LCD 110 ...

Page 111: ...14 3 VDR M95 Camara 111 ...

Page 112: ...14 4 VDR M75 Camera 14 5 VDR M55 M53 Camera 112 ...

Page 113: ...14 6 VDR M95 Packing and Accessory Parts 113 ...

Page 114: ...14 7 VDR M75 M55 M53 Packing and Accessory Parts 114 ...

Page 122: ...C6027 AA01111R CAPACITOR CH 6 3V 1 0U 1 VDR M95 75 122 ...

Page 124: ...C6329 AA00966R CAPACITOR CH 6 3V 4 7U 1 124 ...

Page 126: ...Q6001R CA14091R TRANSISTOR 1 126 ...

Page 128: ...R6025 0790221 RESISTOR CHIP 1 16W 10K 1 128 ...

Page 130: ...R6203L 0790223 RESISTOR CHIP 1 16W 15K 1 130 ...