Manual CT35-IP & CT45IP Last update:December 2013

www.max-power.com

5

positioning and then tightening the two 6mm

∅

screws alternatively using a 5mm Allen

key (maximum torque: 12 Nm).

Check that the propellers rotate freely, without resistance or friction.

It is imperative that the holes and the screws remain free of sealing compound,

otherwise there is a risk of an incorrect assembly of the parts.

Caution: do not use graphite grease.

NOTE:

The composite drive leg:

•

is pre-filled with oil and sealed for life

•

does not require anodes

•

must not be disasembled, even partially (exclusion waranty)

4. ELECTRIC MOTOR (12 volts)

After having greased the motor shaft and the drive pin, place the motor on its support.

The motor should centre itself and align easily when correctly mounted on its support.

If not, the drive leg, motor support and tunnel are incorrectly assembled. Most likely due

to an uneven surface on the outside radius of the GRP tunnel.

If this is the case dissasemble the motor support / drive leg assembly, sand the tunnel so

as to achieve a smooth exterior radius and repeat the previous steps.

Position the four 6 mm

∅

motor support screws, then tighten them alternatively

(maximum torque: 20 Nm).

5. PROPELLER(S)

Insert the drive pin and propeller (to be carried out twice for the CT45-IP duo).

Check that the propeller(s) turn(s) without resistance (a little resistance due to the motor

is normal).

Gradually tighten the 13 mm nut, while holding the propeller tightly with your hand

(maximum torque: 10 Nm).

Protect your hands during this operation to avoid risks of injuries caused by the edges of

the propeller.

IMPORTANT:

to prevent against calcium deposits that damage the seals, we

recommend that you coat the shaft and stainless steel cover with silicon grease.

6. PROTECTION GRILLS

It is possible to install protection grills; however installation of such grills will affect

thruster performance.

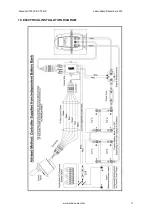

7. ELECTRICAL INSTALLATION

CAUTION:

an incorrect electrical installation will cause rapid deterioration or even failure

of the thruster. Excessive voltage drop will cause premature wearing of the relays and

brushes. Special attention should be given to the quality, capacity and condition of your

batteries, aswell as cable sections used.

Ensure that all electrical connections are correctly tightened.