INSTALLATION MANUAL CT550

7

7.

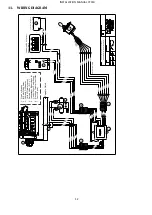

HYDRAULIC (general remarks)

A typical installation of the hydraulic power thruster requires the following elements:

oil reservoir/tank

hydraulic pump

directional control valve

hydraulic motor

circuit piping

oil cooler (depending on type of installation)

The oil reservoir/tank with return filter and suction strainer should be as close to the pump as possible and on

charge. Meaning that the level of the oil should be above the pump, preferably with the oil tank above the water

line.

For future maintenance, make sure that the return filter is easily accessible.

An isolation valve can be fitted

to the suction.

The pump can be driven only by internal combustion engine (crankshaft pulley or gearbox PTO).

For an internal combustion engine with fixed or variable speed, 2 types of pumps can be used, depending on

the unit to be fitted:

Direct PTO:

1. Fixed flow pump (***)

2. Variable displacement pump, depending on the model (**) (*)

3. Fixed flow pump with bypass (**) (*)

PTO with clutch:

1. Fixed flow pump (**) (*)

2. Variable displacement pump depending on the model (**) (*)

3. Fixed flow pump with bypass (**) (*)

(***) always require oil cooler

(**) require oil cooler when time of operation exceeds 15 minutes,

(*) oil cooler not necessary

Note:

The above choices also depend on capacity of the oil tank etc.