13

5. MAINTAIN FOR PERFORMANCE

q DO NOT FIRE THE NAILER WHEN IT IS EMPTY

w USE A 3-PIECE AIRSET

Failure to use a 3-piece airset allows the moisture and dirt inside compressor to pass into the tool

directly. This causes rust and wear, and results in a poor operating performance. The hose length

between airset and tool should be no longer than 5 m since a longer length results in a reduction in air

pressure.

e USE RECOMMENDED OIL

The velocite or turbine oil should be used to lubricate the tool. Upon completion of operations, place

2 or 3 drops of oil into the air plug inlet with the jet oiler. (Recommended Oil : ISO VG32)

r INSPECT AND MAINTAIN DAILY OR BEFORE OPERATION

Disconnect air supply and empty the magazine when inspecting or maintaining the tool.

(1) Drain air line filter and compressor

(2) Keep lubricator filled in air 3-pieces set

(3) Clean filter element of air 3-pieces set

(4) Tighten all screws

(5) Keep contact arm moving smoothly

6. STORING

q When not in use for an extended period, apply a thin coat of the lubricant to the steel parts to avoid

rust.

w Do not store the tool in a cold weather environment. Keep the tool in a warm area.

e When not in use, the tool should be stored in a warm and dry place. Keep out of reach of children.

r All quality tools will eventually require servicing or replacement of parts because of wear from the

normal use.

7. TROUBLE SHOOTING/REPAIRS

The troubleshooting and/or repairs shall be carried out only by the MAX CO., LTD. authorised distributors

or by other specialists.

WARNING:

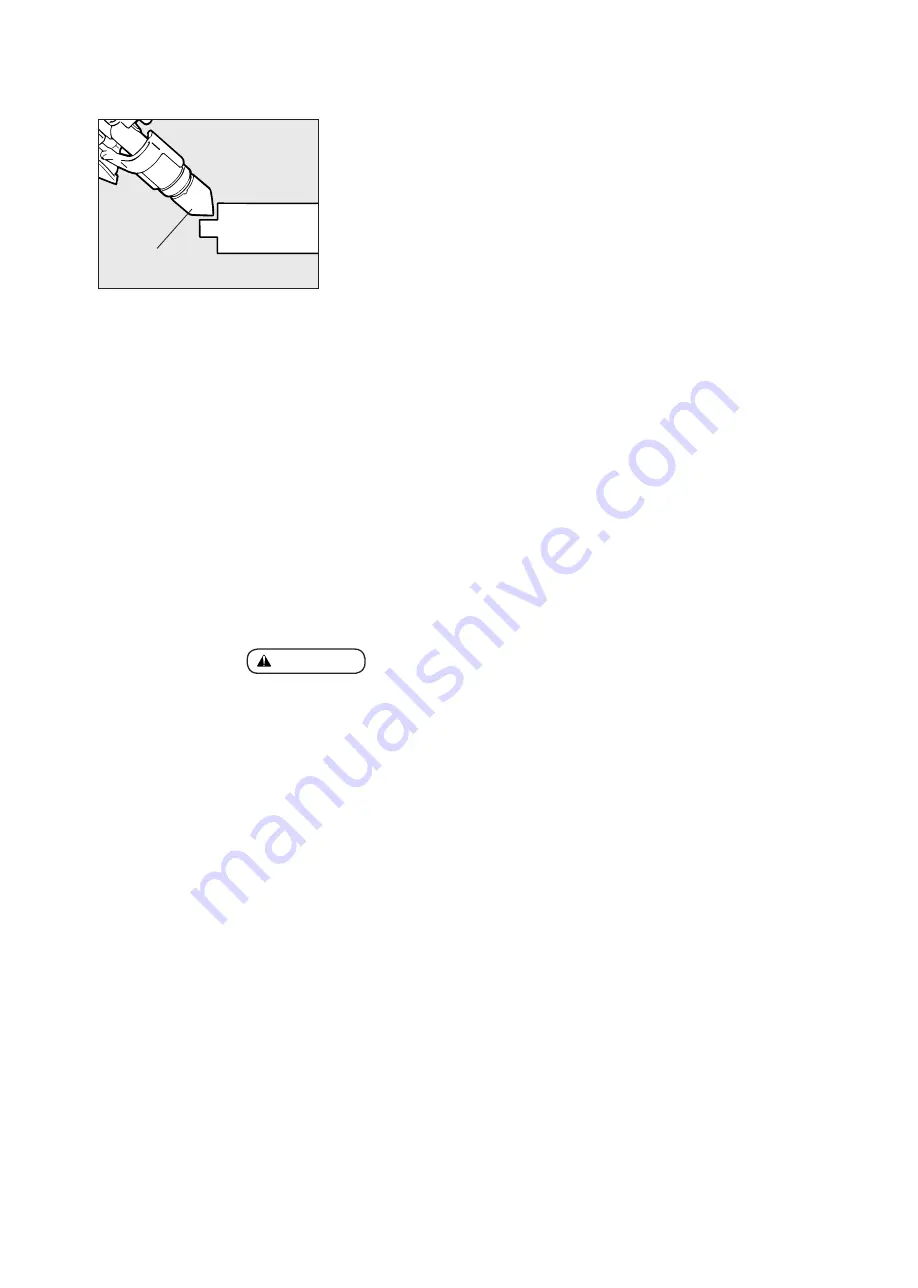

q Mount the metal contact tip firmly, onto the contact arm.

w Metal contact tip can be mounted with tool in horizontal or vertical position.

e Place the tool onto the flooling material as illustrated.

RUBBER CONTACT TIP FOR DRY WALL APPRICATION

Flooring material

Metal contact tip