8

WARNING:

3. AIR SUPPLY AND CONNECTIONS

Read section titled “SAFETY INSTRUCTIONS”.

DO NOT USE ANY POWER SOURCE EXCEPT AN AIR COMPRESSOR

The tool is designed to operate on compressed air. Do not operate the tool on any other highpressure

gas, combustible gases (e.g., oxygen, acetylene, etc.) since there is the danger of an explosion. For this

reason, absolutely do not use anything other than an air compressor to operate the tool.

OPERATE WITHIN THE PROPER AIR PRESSURE RANGE

The tool designed to operate within an air pressure range of 70 to 100 p.s.i. (5 to 7 bar.)

The pressure should be adjusted to the type of the work being fastened. The tool shall never be

operated when the operating pressure exceeds 120 p.s.i. (8 bar.)

DO NOT OPERATE THE TOOL NEAR A FLAMMABLE SUBSTANCE

Never operate the tool near a flammable substance (e.g., thinner, gasoline, etc.). Volatile fumes from

these substances could be drawn into the compressor and compressed together with the air and this

could result in an explosion.

DO NOT USE A WRONG FITTINGS

The connector on the tool must not hold pressure when air supply is disconnected. If a wrong fitting is

used, the tool can remain charged with air after disconnecting and thus will be able to drive a fastener

even after the air line is disconnected, possibly causing injury.

DISCONNECT THE AIR CHUCK WHEN THE TOOL IS NOT IN USE

Always disconnect the air chuck from the tool when operation has been completed or suspended, when

moving to a different work area, adjusting, disassembling, or repairing the tool, and when clearing a

jammed fastener.

FITTINGS:

Install a male plug on the tool which is free flowing and which will release

air pressure from the tool when disconnected from the supply source.

HOSES:

Hose has a min. ID of 1/4˝ (6 mm) and max. length of no more than 17˝ (5

meters).

The supply hose should contain a fitting that will provide “quick disconnecting” from

the male plug on the tool.

SUPPLY SOURCE:

Use only clean regulated compressed air as a power source for

the tool.

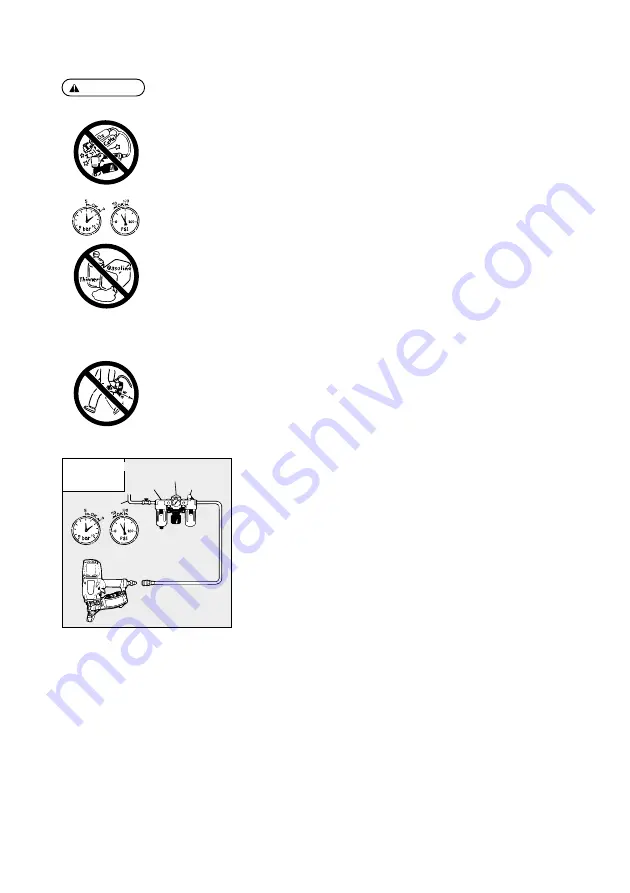

3-PIECE AIRSET

(Air filter, Regulator, Oiler):

Refer to TOOL SPECIFICATIONS for setting the correct operating pressure for the

tool.

NOTE:

A filter will help to get the best performance and minimum wear from the tool because dirt and water in

the air supply are major causes of wear in the tool.

Frequent, but not excessive, lubrication is required for the best performance. Oil added thru the air line

connection will lubricate the internal parts.

Air compressor

[AIR SUPPLY & CONNECTIONS]

Air filter

Air hose

Oiler

Used at 70 to 100 p.s.i. (5 to 7 bar)

Regulator

[AIR SUPPLY & CONNECTIONS]

3-piece airset

Summary of Contents for CN650M

Page 15: ...16...