4. INSTRUCTIONS FOR OPERATION

Read section titled “SAFETY INSTRUCTIONS”.

1.

BEFORE OPERATION

①

Wear Safety Glasses or Goggles.

②

Do not connect the air supply.

③

Inspect screw tightness.

④

Check operation of the contact arm & trigger if moving smoothly.

⑤

Connect the air supply.

⑥

Check the air-leakage. (The Tool must not have the air-leakage.)

⑦

Hold the Tool with finger-off the trigger, then push the contact arm against the work-piece. (The tool must

not operate.)

⑧

Hold the Tool with contact arm free from work-piece and pull the trigger. (The Tool must not operate.)

⑨

Disconnect the air supply.

2.

OPERATION

Wear safety glasses or goggles

Danger to the eyes always exists due to the possibility of dust being blown up by the exhausted air or of a

fastener flying up due to the improper handling of the tool. For these reasons, safety glasses or goggles shall

always be worn when operating the tool.

The employer and/or user must ensure that proper eye protection is worn. Eye protection equipment must

conform to the requirements of the American National Standards Institute, ANSI Z87.1 (Council Directive

89/686/EEC of 21 DEC. 1989) and provide both frontal and side protection.

The employer is responsible to enforce the use of eye protection equipment by the tool operator and all other

personnel in the work area.

NOTE:

Non-side shielded spectacles and face shields alone do not provide adequate protection.

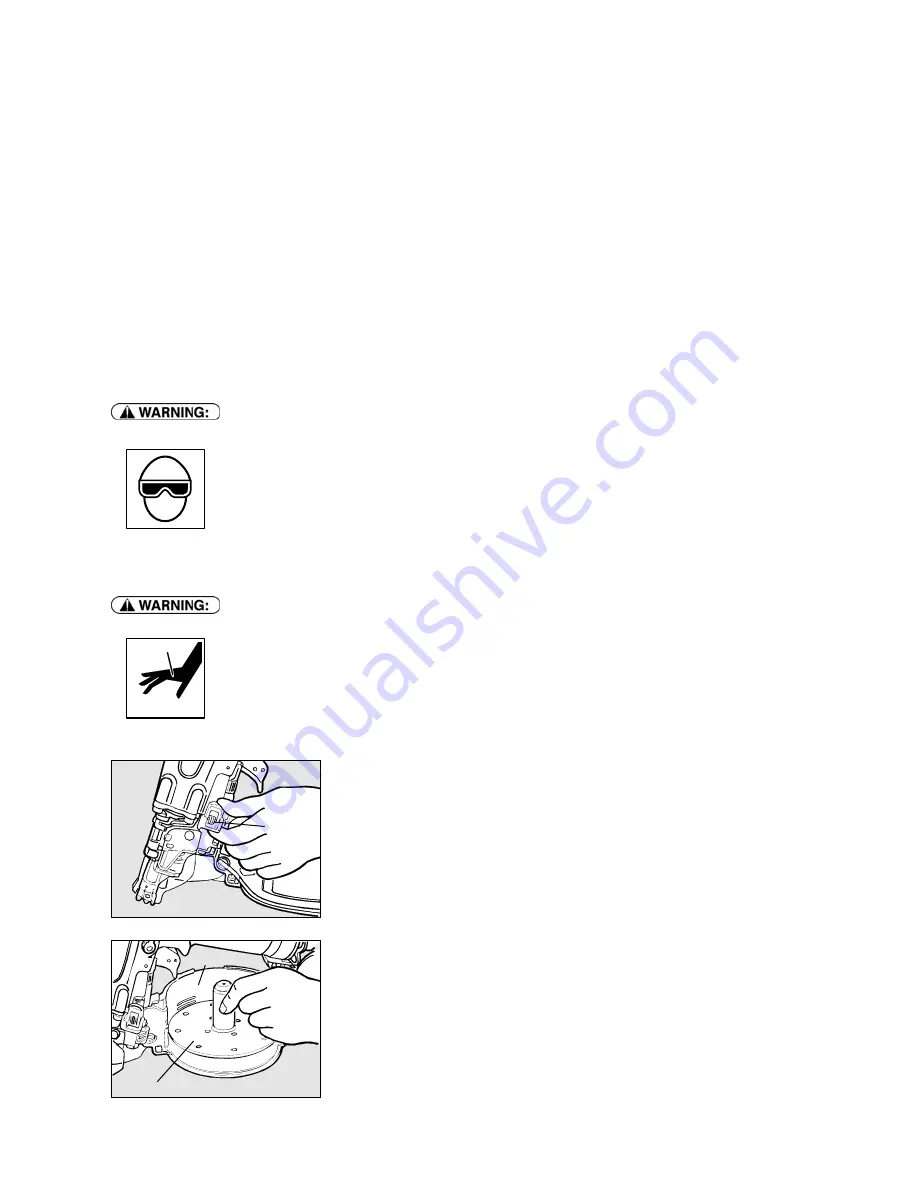

Keep hands and body away from the discharge outlet when driving the fasteners because of dangerous of

hitting the hands or body by mistake.

NAIL LOADING

①

Open the Magazine:

Pull up Door Latch and swing Door open. Swing Magazine Cover open.

Door Latch

②

Check adjustment:

Magazine

The Nail Support can be moved up and down to four settings. To change setting pull up

on the Nail Post and twist to the correct step. The Nail Support should be adjusted

correctly to the position indicated in inches and millimeters inside Magazine.

Nail Support

10

Summary of Contents for HN50

Page 16: ...16...