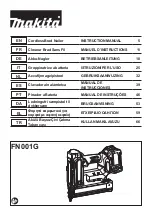

CONTACT FIRE OPERATION (CONTACT TRIP)

For contact fire operation, hold the Trigger and depress the Contact Arm against the work surface.

PROCEDURE

①

Hold the Trigger.

②

Depress the Contact Arm.

SINGLE FIRE OPERATION (ANTI-DOUBLE FIRE MECHANISM AND SEQUENTIAL TRIP)

For single fire operation, depress the Contact Arm against the work surface and pull the Trigger. Tool can not

fire a second nail until the Trigger is released and tool can cycle.

PROCEDURE

①

Depress the Contact Arm.

②

Pull the Trigger.

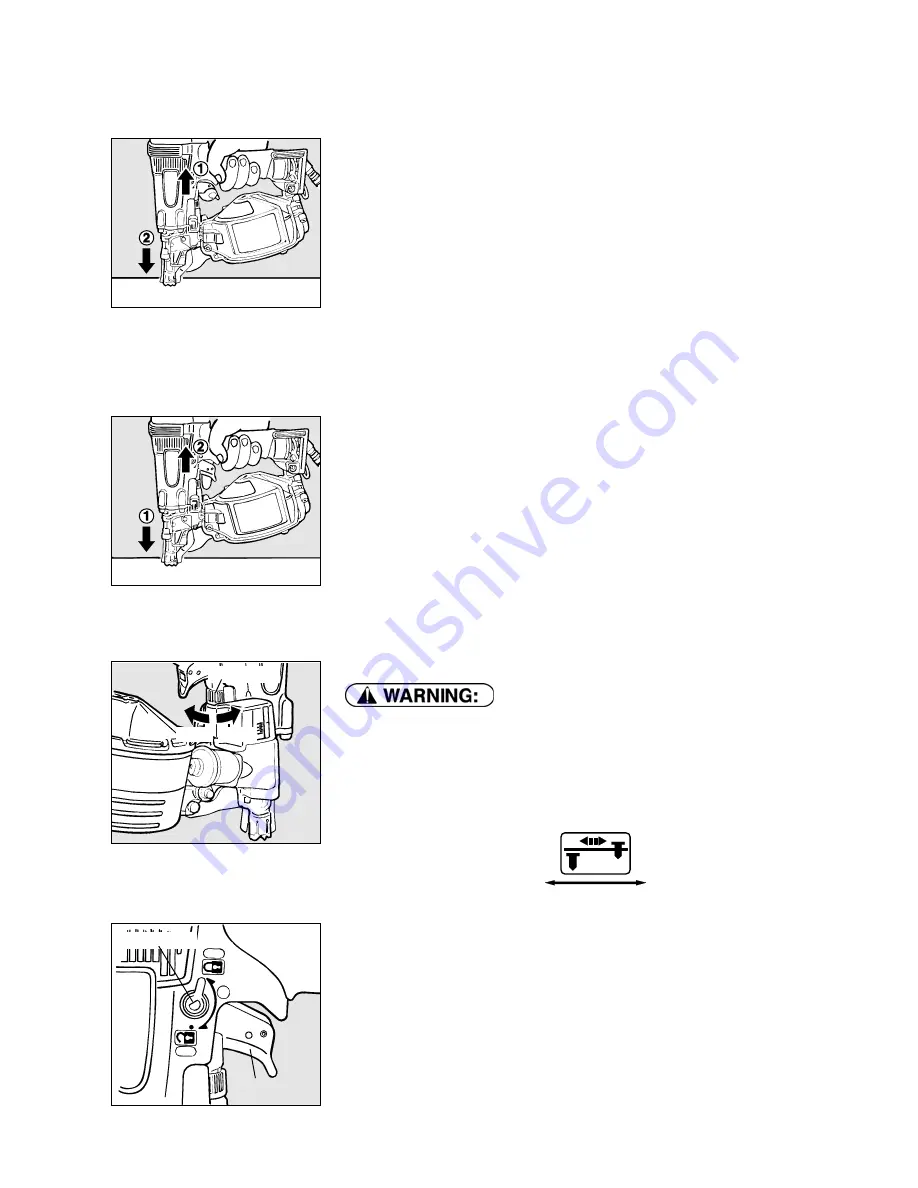

DRIVING DEPTH ADJUSTMENT DIAL

Deeper Shallow

Trigger Lock Dial

Adjustment Dial

ALWAYS disconnect air supply before adjustment dial.

①

With air pressure set, drive nails into a representative material sample to determine if

adjustment is necessary.

②

If adjustment is required, disconnect air supply.

③

Refer to the mark on the Adjust Spacer for direction to turn the adjustment dial.

④

Reconnect air supply.

Deeper

Shallow

TRIGGER LOCK MECHANISM

The tool is equipped with a Trigger Lock Mechanism. Push and rotate Trigger Lock Dial

from the LOCK to the UNLOCK position before driving nails.

Trigger

13

Summary of Contents for HN50

Page 16: ...16...