10

DRIVING FASTENERS

NOTE :

This tool is shipped with SEQUENTIAL TRIP selected.

SEQUENTIAL TRIP

The Sequential Trip requires the operator hold the tool against

the work before pulling the trigger.

This makes accurate fastener placement easier, for instance on

framing, toe nailing and crating applications.

The Sequential Trip allows exact fastener location without the pos-

sibility of driving a second fastener on recoil, as described under

"Contact Trip".

The Sequential Trip Tool has a positive safely advantage be-

cause it will not accidentally drive a fastener if the tool is contact-

ed against the work or anything else-while the operator is holding

the trigger pulled.

Switching SEQUENTIAL TRIP to CONTACT TRIP

ALWAYS-disconnect air supply before switching the trigger-

ing method.

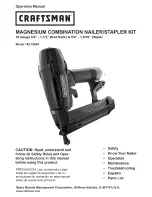

1

Press the button on the trigger.

2

Turn the switching lever in the direction of the arrow.

3

Set the switching lever as above picture.

CONTACT TRIP

The common operating procedure on "Contact Trip" tools is for

the operator to contact the work to actuate the trip mechanism

while keeping the trigger pulled, thus driving a fastener each time

the work is contacted.

All pneumatic tools are subject to recoil when driving fasteners.

The tool may bounce, releasing the trip, and if unintentionally al-

lowed to recontact the work surface with the trigger still actuated

(finger still holding trigger pulled) an unwanted second fastener

will be driven.

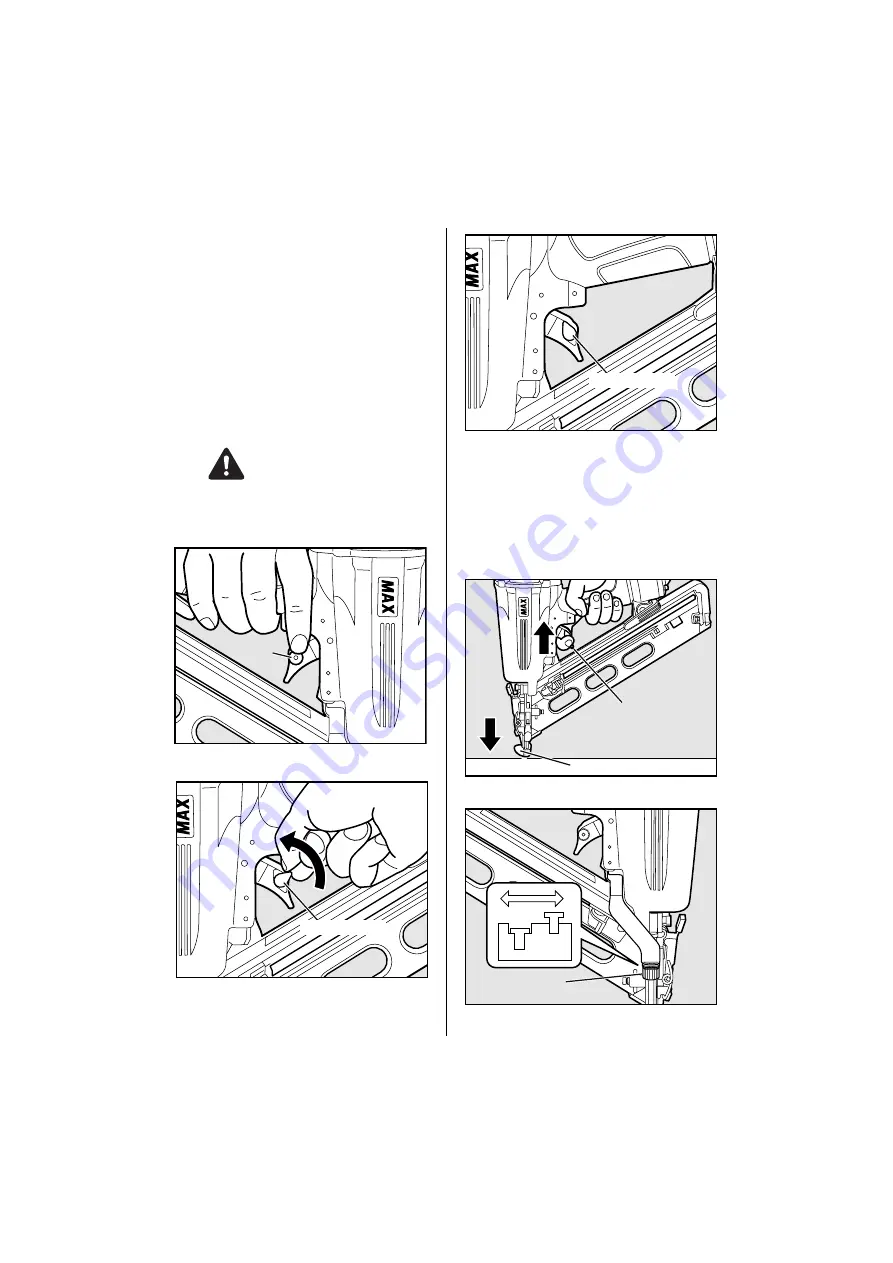

DRIVING DEPTH ADJUSTMENT DIAL

WARNING

Button

Switching lever

Switching lever

Trigger

Contact arm

Adjustment dial