7

3. SPECIFICATIONS AND TECHNI-

CAL DATA

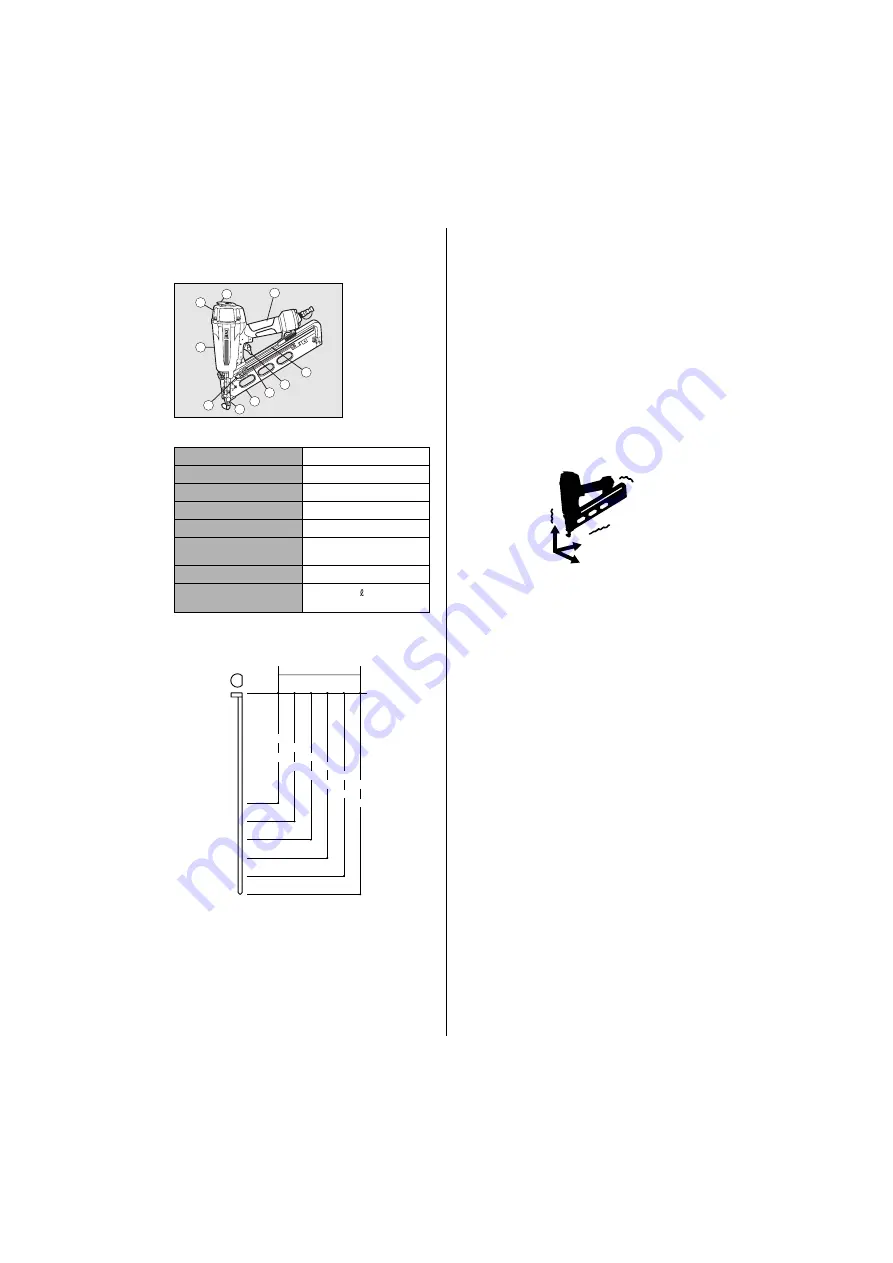

1.

NAME OF PARTS

2.

TOOL SPECIFICATIONS

∗

The machine has been compactly designed in order to im-

prove operating weight balance.

3.

BRAD NAIL SPECIFICATIONS

TOOL AIR FITTINGS:

This tool uses a 1/4" N.P.T. male plug. The inside diameter

should be .28" (7mm) or larger. The fitting must be capable of dis-

charging tool air pressure when disconnected from the air supply.

RECOMMENDED OPERATING PRESSURE:

70 to 100 p.s.i. (5 to 7 bar). Select the operating air pressure with-

in this range for best fastener performance.

DO NOT EXCEED 120 p.s.i. (8.3 bar).

4.

TECHNICAL DATA

1

NOISE

A-weighted single-event sound power level

NF665/15------ LWA, 85.5 dB

A-weighted single-event emission sound pressure level at

work station

NF665/15------ LpA, 79.4 dB

These values are determined and documented in accord-

ance to EN12549 : 1999.

2

VIBRATION

Vibration characteristic value

= 3.2 m/s

2

These values are determined and documented in accord-

ance with ISO 8662-11.

This value is a tool-related characteristic value and does not

represent the influence to the hand-arm-system when using

the tool. An influence to the hand-arm-system when using

the tool will, for example, depend on the gripping force, the

contact pressure force, the working direction, the adjust-

ment of mains supply, the workpiece, the workpiece sup-

port.

5.

APPLICATIONS

∗

Door and window casings

∗

Plywood, decorative boards, and other interior finish works

∗

Panel assembly and moldings

∗

Sub flooring

∗

Furniture assembly including drawer assembly, case back

nailing, blind pinning, and other finishing works

∗

Cabinet assembly

1

Frame

2

Cylinder Cap

3

Exhaust Port

4

Magazine

5

Slider Unit

6

Trigger

7

Grip

8

Warning Label

9

Outlet

0

Pusher

PRODUCT NO.

NF665/15

HEIGHT

12-5/8" (322 mm)

WIDTH

3-11/16" (94 mm)

LENGTH

12-5/8" (322 mm)

WEIGHT

3.97 lbs (1.8 kg)

RECOMMENDED

OPERATING PRESSURE

70 to 100 p.s.i.

(5 to 7 bar)

LOADING CAPACITY

106 Nails

AIR CONSUMPTION

0.096 ft

3

(2.7 ) at 7 bar

operating pressure

9

10

6

5

4

2

1

7

3

8