4

DRIVING DEPTH ADJUSTMENT DIAL

Adjust the driving depth by twisting the adjustment dial

b

as in-

dicated below.

TRIGGER LOCK MECHANISM (Fig.13)

This tool has a Trigger Lock. The trigger should be locked at all

times until you intend to drive nail into the work surface. Push and

rotate the Trigger LOCK Dial

1

clockwise from LOCK to UN-

LOCK position immediately before driving nails. When fastening

is complete, push and rotate switch counterclockwise to LOCK

position.

CONTACT TIP (Fig.14) (HN90F, HN65)

Attach the Contact Tip

1

on the tip of Contact Arm

2

, when driv-

ing nails to a soft material.

The Contact Tip can be kept on the Arm Cover

3

when not using.

REMOVING JAMMED NAILS (Fig.15)

• ALWAYS disconnect the air supply.

• Wear gloves when removing jams; do not use bare hands

• Confirm that you have removed all nails from nose of tool

before reconnecting to air supply.

1

Disconnect the air supply.

2

Open the tool door and remove nails from inside of the mag-

azine.

3

Insert a thin metal stick in the tool nose and hit the metal

stick with a hammer or remove the jam with a flathead

screwdriver.

4

Put back the nails on the feed pawl and close the tool door.

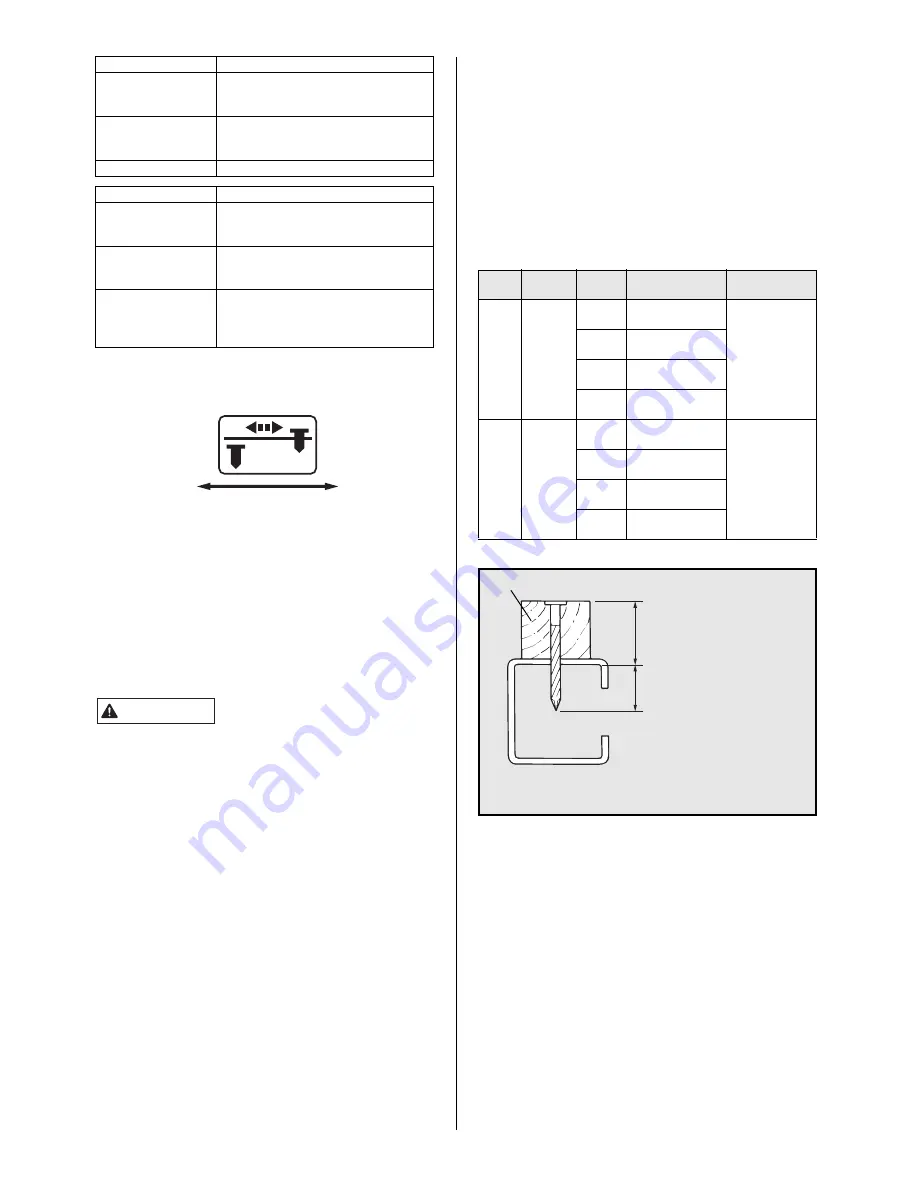

WHEN USING THE TOOL FOR STEEL PLATES

(HN90F, HN65)

(HN65) This tool is exclusively designed for 1.6mm / 16Ga. to

2.3mm / 13Ga. thick light gauge steel.

(HN90F) This tool is exclusively designed for 1.6mm / 16Ga. to

3.2mm / 11Ga. thick light gauge steel.

When using it, comply with the Work Standards, considering the

object condition and work site environment.

1

Select appropriate nails according to the object thickness,

seeing the Nail Selection Criteria Chart.

∗

The nails may not be driven into the object depending on its

hardness or thickness.

∗

If the object is thicker than an appropriate range of thickness,

the nails may not be driven into it because of being bent.

2

If the thickness of the light gauge steel foundations material

used is 3.2mm / 11Ga., use the 2.9mm / .113" nails for steel

plate. (HN90F)

3

Never drive the nails directly into the light gauge steel be-

cause they will fly off, endangering you.

4

Be sure to apply the discharge outlet to the object at a right

angle. If applied obliquely, the nails will fly off, endangering

you.

5

Never use the nails for the roofs (roof foundations included)

or ceilings (ceiling foundations included).

6

If the nails are driven into the steel plate too deeply, their

holding force will be extremely reduced. When working with

the tool, fully check the driven conditions.

Nail Selection Criteria

REPLACING THE AIMING GUIDE LOCATOR

(HN65J)

The aiming guide locator is worn out depending on the frequency

of use.

If the machine cannot be easily held vertically when setting the

aiming guide locator in a hole in a metal fitting, it is about time to

replace.

Replace it in the following procedure:

1

(Fig.16) Remove a rubber washer

1

with a regular

screwdriver to pull out a pin

2

. Push the nail leg guide

3

to remove the aiming guide locator

4

.

2

(Fig.17) Attach a new aiming guide locator, set the pin and put

back the rubber washer.

When replacing the aiming guide locator, contact the nearest

MAX CO., LTD. authorized distributor.

CHANGING THE HOOK DIRECTION (HN90F)

(Fig.18) The hook can be directed in the two direction. Remove

the hexagon socket cap screw with hexagon wrench, change the

direction, and then, put back the bolt to reassemble.

PROCEDURE

1

Pulling the Trigger and keeping it

pulled.

2

Depressing the Contact Arm.

CONTACT TRIP WITH

ANTI-DOUBLE FIRE

MECHANISM

The tool fires a nail each time when the

Contact Arm is depressed.

SEQUENTIAL TRIP

The tool cannot fire a nail.

PROCEDURE

1

Depressing the Contact Arm.

2

Pulling the Trigger and keeping it

pulled.

CONTACT TRIP WITH

ANTI-DOUBLE FIRE

MECHANISM

The tool fires a nail.

The tool cannot fire a second nail until

the Trigger is released.

SEQUENTIAL TRIP

The tool fires a nail.

In order to fire a second nail, you should

both release the Trigger and remove the

Contact arm from the surface.

Deep

Shallow

WARNING

Tool Diameter Length

Object thickness

(Total) range

Light gauge

steel thickness

HN65

HN90F

2.5mm

(.098")

45mm

(1-3/4")

25 to 35mm

(1" to 1-3/8")

1.6 to 2.3mm

(16Ga. to

13Ga.)

50mm

(2")

30 to 40mm

(1-1/8" to 1-1/2")

57mm

(2-1/4")

35 to 45mm

(1-3/8" to 1-3/4")

65mm

(2-1/2")

45 to 55mm

(1-1/2" to 1-1/8")

HN90F

2.9mm

(.113")

45mm

(1-3/4")

25 to 35mm

(1" to 1-3/8")

1.6 to 3.2mm

(16Ga. to

11Ga.)

50mm

(2")

30 to 40mm

(1-1/8" to 1-1/2")

57mm

(2-1/4")

35 to 45mm

(1-3/8" to 1-3/4")

65mm

(2-1/2")

45 to 55mm

(1-1/2" to 1-1/8")

Wood

Object thickness

(Total) range

Penetration amount

Light gauge steel:

(HN65) 1.6mm (16Ga.) to 2.3mm

(13Ga.) thick

(HN90F) 1.6mm (16Ga.) to 3.2mm

(11Ga.) thick

∗

For the 3.2mm (11Ga.) thick light gauge steel, use the

2.9mm (.113") nails for steel plates. (HN90F)

All manuals and user guides at all-guides.com