ADVANTIX

SPA

Via

Mansoldo

Gettuglio

–

Loc.

La

Macia

Z.A.I

–

37040

ARCOLE

(Verona)

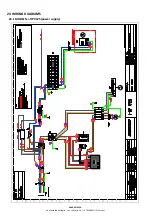

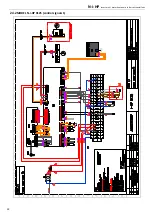

The

following

are

present

the

standard

connections.

Other

connections

and

configurations

are

shown

in

the

manual

control

(the

permissible

configurations

tables

for

user

and

installer).

TERMINAL

TYPE

CONNECTION

AI1E

Analogue

input

NTC

ST3E

Terminal

input

for

remote

plant

temperature

probe

(optional)

AI1E

Analogue

input

NTC

ST3E

Terminal

input

for

remote

plant

temperature

probe

(optional)

AID1E

Digital

input

DI6E

expansion

board

Input

terminal

for

double

set

‐

point

consent

(only

if

Hi

‐

T

not

presents)

AID1E

Digital

input

DI6E

expansion

board

Input

terminal

for

double

set

‐

point

consent

(only

if

Hi

‐

T

not

presents)

DO1EN

Digital

output

230

Vac

(DO1E)

expansion

board

Neutral

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

for

power

on

the

contactor

coil

of

sanitary

integrative

heater

(not

supplied)

DO1E

Digital

output

230

Vac

(DO1E)

expansion

board

Neutral

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

for

power

on

the

contactor

coil

of

sanitary

integrative

heater

(not

supplied)

DO2EN

Digital

output

230

Vac

(DO2E)

expansion

board

Neutral

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

for

power

on

the

contactor

coil

of

sanitary

integrative

heater

(not

supplied)

DO2E

Digital

output

230

Vac

(DO2E)

expansion

board

Neutral

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

for

power

on

the

contactor

coil

of

sanitary

integrative

heater

(not

supplied)

DO3EN

Digital

output

230

Vac

(DO3E)

expansion

board

Neutral

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

for

boiler

consent

(voltage

output,

use

a

relay)

DO3E

Digital

output

230

Vac

(DO3E)

expansion

board

Neutral

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

for

boiler

consent

(voltage

output,

use

a

relay)

NO1E

Digital

output

230

Vac

(NO

contact)

expansion

board

Power

supply

phase

NO

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

double

setpoint

3

way

valve

for

radiant

panels

(optional)

(if

the

contact

is

active

the

valve

must

be

turn

to

floor

side)

N1E

Neutral

terminal

power

supply

(230V

AC)

double

setpoint

3

way

valve

for

radiant

panels

(optional)

NC1E

Digital

output

230

Vac

(NC

contact)

expansion

board

Power

supply

phase

NC

terminal

(230V,

50Hz,

5A

resistive,

1

A

inductive)

double

setpoint

3

way

valve

for

radiant

panels

(optional)

(if

the

contact

is

active

the

valve

must

be

turn

to

fancoil

side)

8

START

UP

Before

start

‐

up:

Check

out

the

availability

of

the

supplied

wiring

diagrams

and

manuals

of

the

installed

appliance.

Check

out

the

availability

of

the

electrical

and

hydraulic

diagrams

of

the

plant

in

which

the

unit

is

installed.

Check

that

the

shut

‐

off

valves

of

the

hydraulic

circuits

are

open.

Verify

that

the

hydraulic

circuit

has

been

charged

under

pressure

and

air

vented.

Check

out

that

all

hydraulic

connections

are

properly

installed

and

all

indications

on

unit

labels

are

respected.

Check

if

all

power

cables

are

properly

connected

and

all

terminals

are

tightly

fixed.

Check

if

the

electrical

connections

are

performed

according

to

the

norms

in

force

including

the

grounding

connection.

Check

if

the

voltage

is

that

shown

in

the

unit

labels.

Make

sure

the

voltage

is

within

the

limits

(±5%)

of

tolerance

range.

Check

if

the

electric

heaters

of

the

compressors

are

powered

correctly.

Make

sure

that

there

is

no

refrigerant

leak.

Be

sure

that

all

the

cover

panels

are

installed

in

their

proper

positions

and

locked

with

fastening

screws

before

start

up.

If

the

first

start

up

of

the

machine

does

not

turn

the

display

on

of

the

controller,

you

must

reverse

the

phase

sequence

of

the

power

supply

cable.

WARNING:

The

unit

must

be

connected

to

the

electrical

network

and

should

be

in

STAND

‐

BY

mode

(powered)

closing

the

general

switch

in

order

to

operate

the

crankcase

heaters

of

the

compressor

for

a

minimum

of

12

hours

before

start

up.

(the

heaters

are

automatically

powered

when

the

main

switch

is

switched

off).

The

crankcase

heaters

are

working

properly

if,

after

some

minutes,

the

temperature

of

crankcase’s

compressor

is

about

10°C

÷

15°C

higher

than

ambient

temperature.

WARNING:

Never

switch

off

the

unit

(for

a

temporary

stop)

by

switching

off

the

main

switch:

this

component

should

be

used

to

disconnect

the

unit

from

the

power

supply

only

for

lengthy

stoppages

(e.g.

seasonal

stoppages).

Besides,

failing

the

power

supply,

the

crankcase’s

heaters

are

not

supplied

thus

resulting

in

a

possible

breakdown

of

the